Text: Thomas Masuch

Meanwhile, the manufacture of watches, rings, or necklaces is nowhere near as regulated as fields like medicine or aviation – rather the opposite, in fact. While other industries are very much concerned with the challenge of things like repeatability, the jewelry industry focuses on other properties, such as surface quality.

Although the jewelry industry has been involved in the Additive Manufacturing of prototypes and wax molds and the laser melting of gold rings for more than 20 years, it is only more recent technological advances (including in the field of binder jetting or Micro 3D Printing) that have led to a significant increase in the breadth of additive applications. This is now also reflected in strong market development (see below).

Rings, watches, and crystal

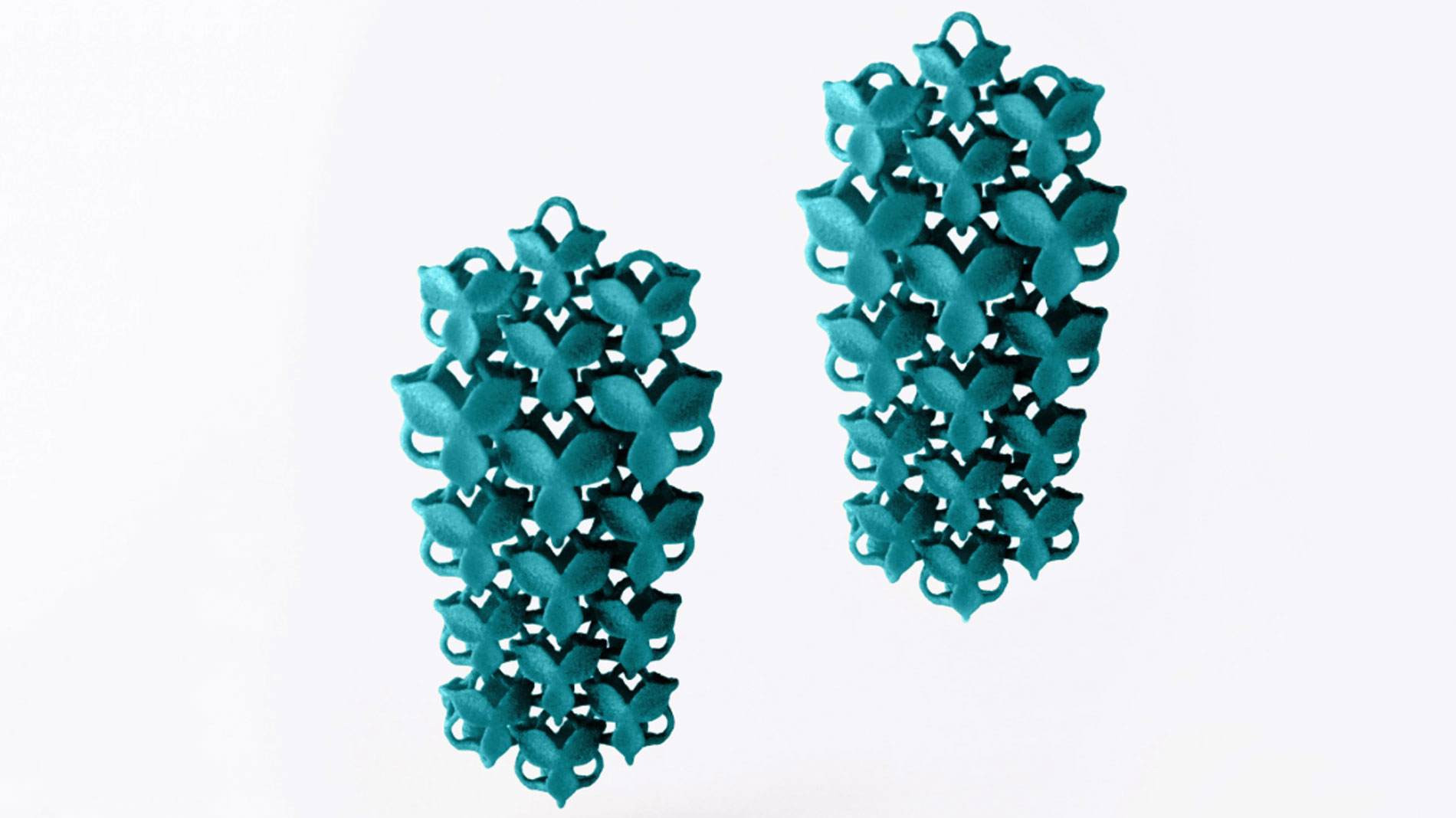

One of the pioneers of 3D Printing in the jewelry industry is Marie Boltenstern, a jewelry designer from Vienna who took over her father's brand in 2015 and subsequently made a name for herself in 3D Printing jewelry. In addition to her collections based on 3D-printed plastic, her jewelry pieces are now also made of yellow gold combined with gemstones, for example. Boltenstern also emphasizes the sustainable aspect of 3D Printing through advantages like on-demand manufacturing and low-waste production.

The British company Cooksongold, meanwhile, has been involved in the 3D Printing of precious metals for many years and has an extensive machine park with several systems from EOS and Renishaw. The company also atomizes various precious metals, such as gold, silver, palladium, and platinum. In the autumn of 2024, Cooksongold opened its new Cookson Industrial division to extend its expertise to sectors beyond jewelry.

Other renowned companies in the industry are also increasingly using Additive Manufacturing. The Italian company Legor, for instance, has now set up a 3D Printing department alongside its traditional business. India’s Jaipur Watch Company offers 3D-printed watches (although its stainless-steel models were sold out as of May 26 according to the company’s website). The French watch manufacturer A.L.B Watches integrates 3D-printed dials into various models and cooperates with the French AM service provider Sculpteo. The Dutch watch manufacturer Holthinrichs prints watch cases in stainless steel, titanium, platinum, and other materials while offering its customers the opportunity to customize watches with 3D-printed texts or other individual details.

New technologies

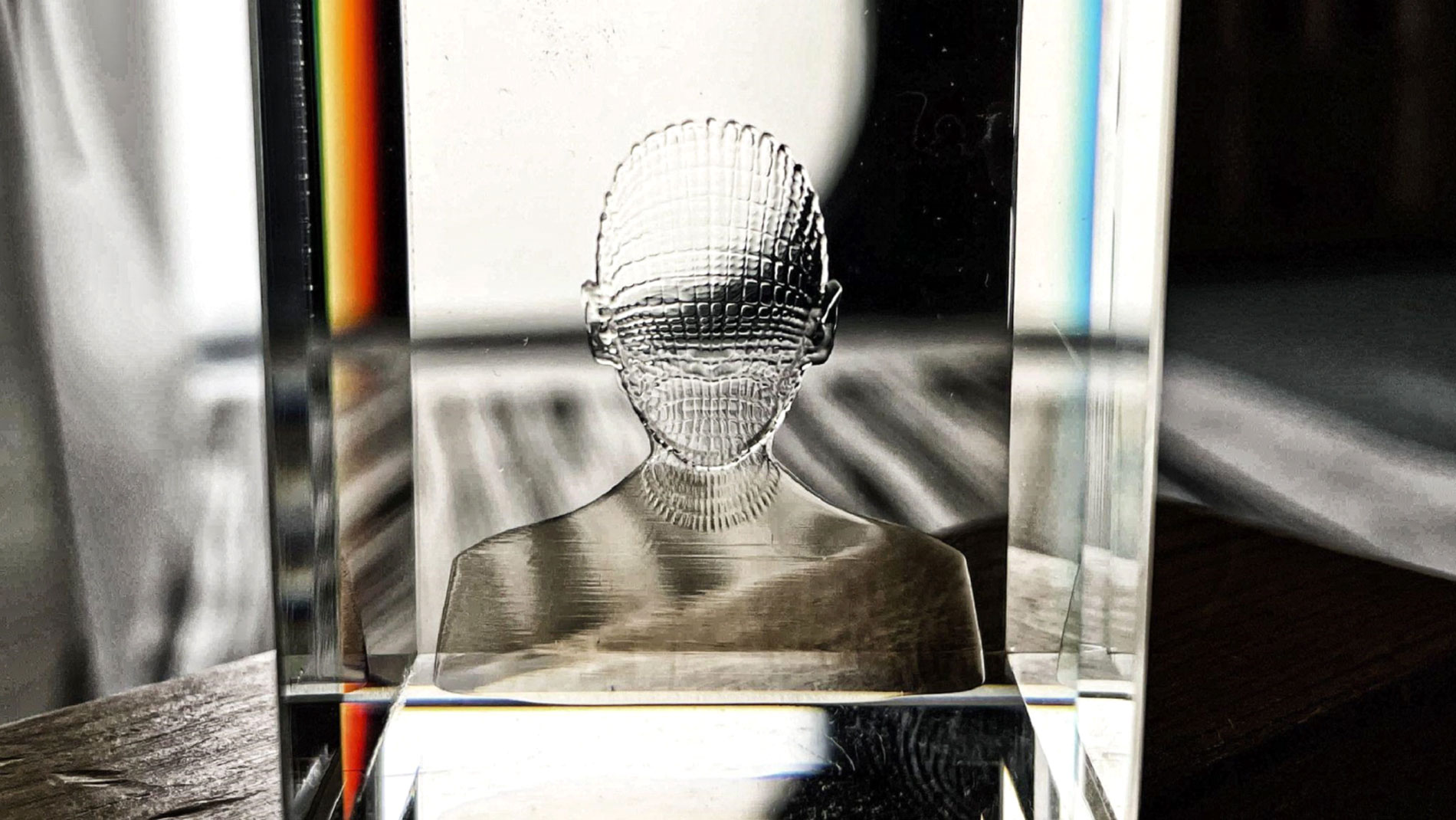

New technological developments are now also being quickly adapted by the jewelry industry. For example, the traditional company Swarowski (founded in 1895) announced a cooperation with Xolo in the autumn of 2024. This young 3D Printing company from Berlin specializes in 3D-printing glass, among other things. The aim of the collaboration is to “combine luxury and creativity in a completely new way”, as the companies have stated.

AM offers greater flexibility

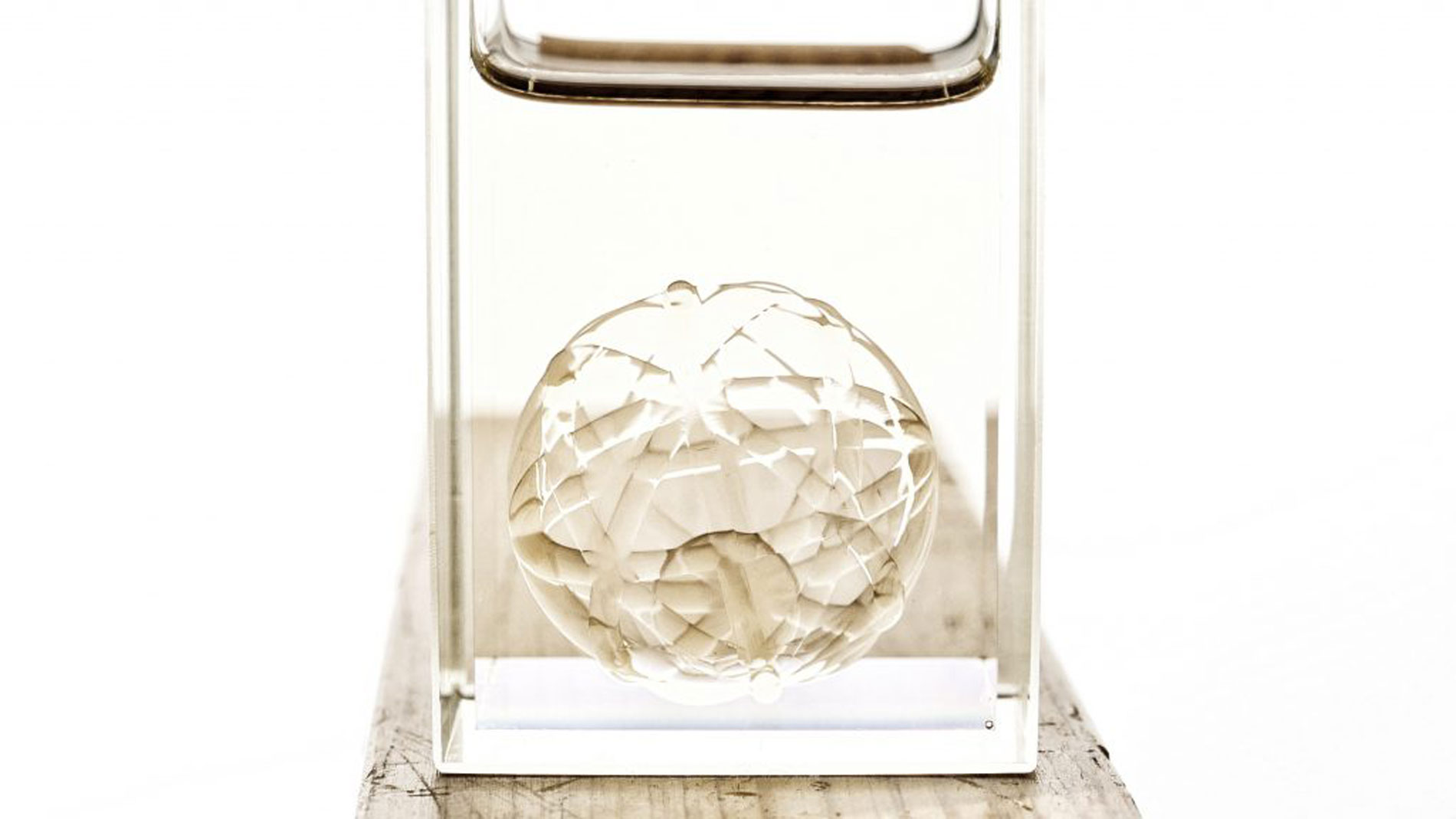

With such a dynamic development in the jewelry and luxury goods industry, it is not surprising that the sector continued to push its way into the limelight at Formnext 2024. Maurizio Ficcadenti – global R&D manager at Balaran, a long-established Italian manufacturer of packaging solutions for the cosmetics industry – presented a perfume bottle of seemingly outstanding quality at the Stratasys booth. Its 3D-printed surface sparkled in the spotlight of the exhibition hall as if it were set with diamonds. Having discovered 3D Printing four years ago, it has now been nearly two years since Balaran developed a process that offers a solution to the challenge of 3D-printed plastic sticking to glass. According to Ficcadenti, one of the advantages of this solution is its greater flexibility: “We normally produce millions of bottles for large brands, but with 3D Printing, we can efficiently offer customized products in smaller quantities in the range of several hundred.”

At Formnext 2024, Maurizio Ficcadenti, Global R&D Manager at Balaran, presented perfume bottles that were 3D-printed to give them an elegant, crystal-like appearance. Images: Thomas Masuch

3D Printing growing significantly faster than the jewelry market

The growth of 3D Printing in the jewelry industry is also reflected in the figures from market analyses, although estimates of the market’s size vary considerably. They range from US$489 million (2023, SmarTech Analysis) or US$841.7 million (2023, Grand View Research) to US$3.57 billion (2024, Business Research Company) or US$5 billion (2025, The Brainy Insights). At the same time, these four analyst firms predict annual growth of 10–20% over the next few years.

If these growth forecasts are accurate, 3D Printing is set to become significantly more important throughout the jewelry world. The key drivers include a further growing desire for more flexibility, design freedom, and sustainability. Compared to the 3D Printing of jewelry, the entire global market for jewelry and watches – which, according to Statista, is expected to generate sales of €457 billion in 2025 – will grow by “only” 4.65% per year over the next four years. As in many other sectors, the global jewelry world is also poised to get important impetus from the Far East: China is already the most important player worldwide, with a market volume of €128 billion.

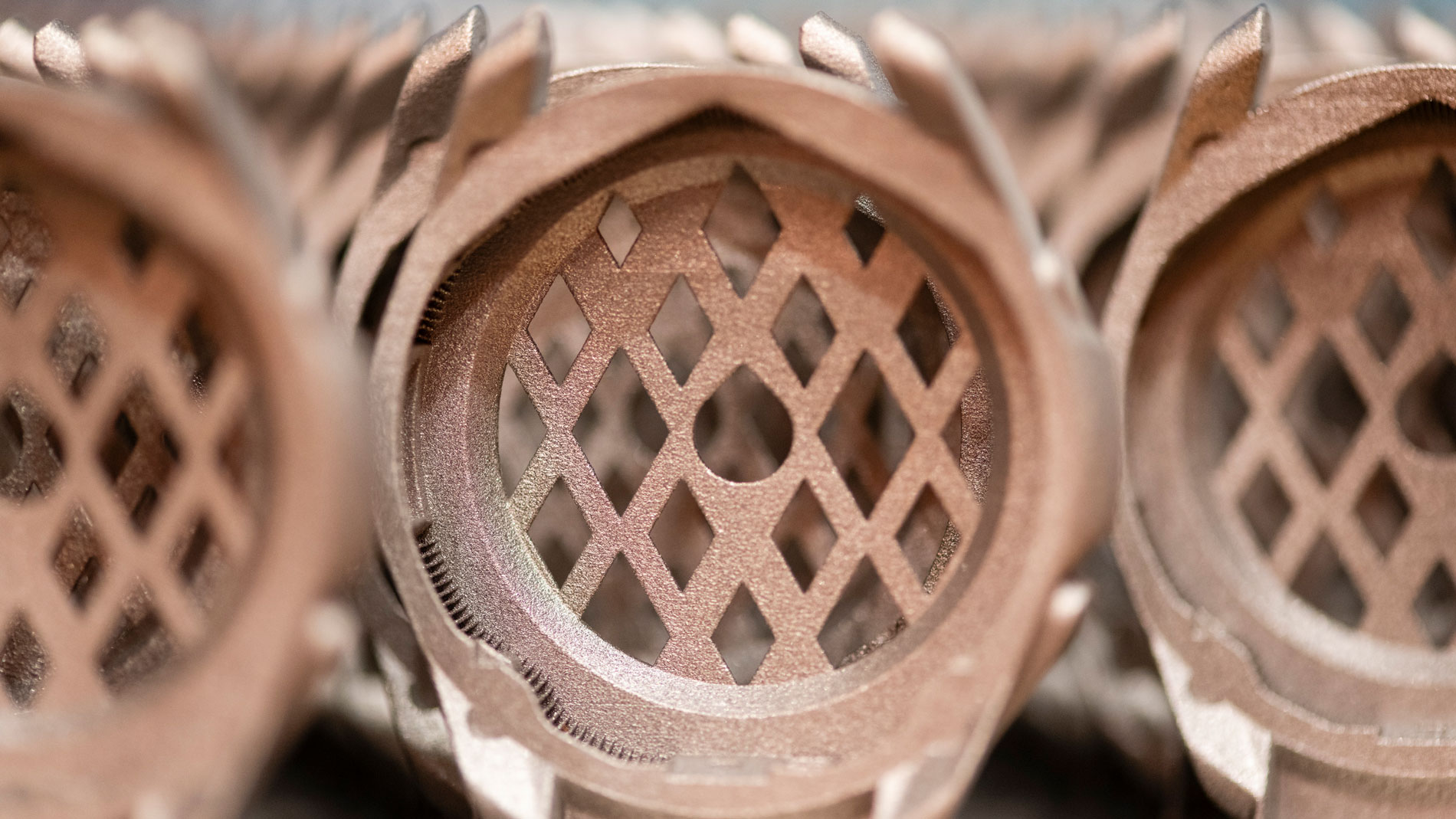

China is an important player and sales market in the global jewelry industry – no wonder that Chinese manufacturers such as Addireen also presented 3D-printed jewelry at Formnext 2024. Here are some examples of a plated copper-chromium-zirconium alloy Images: Thomas Masuch

Further Information

https://www.cookson-industrial.com/