BMF: Compact blasting system

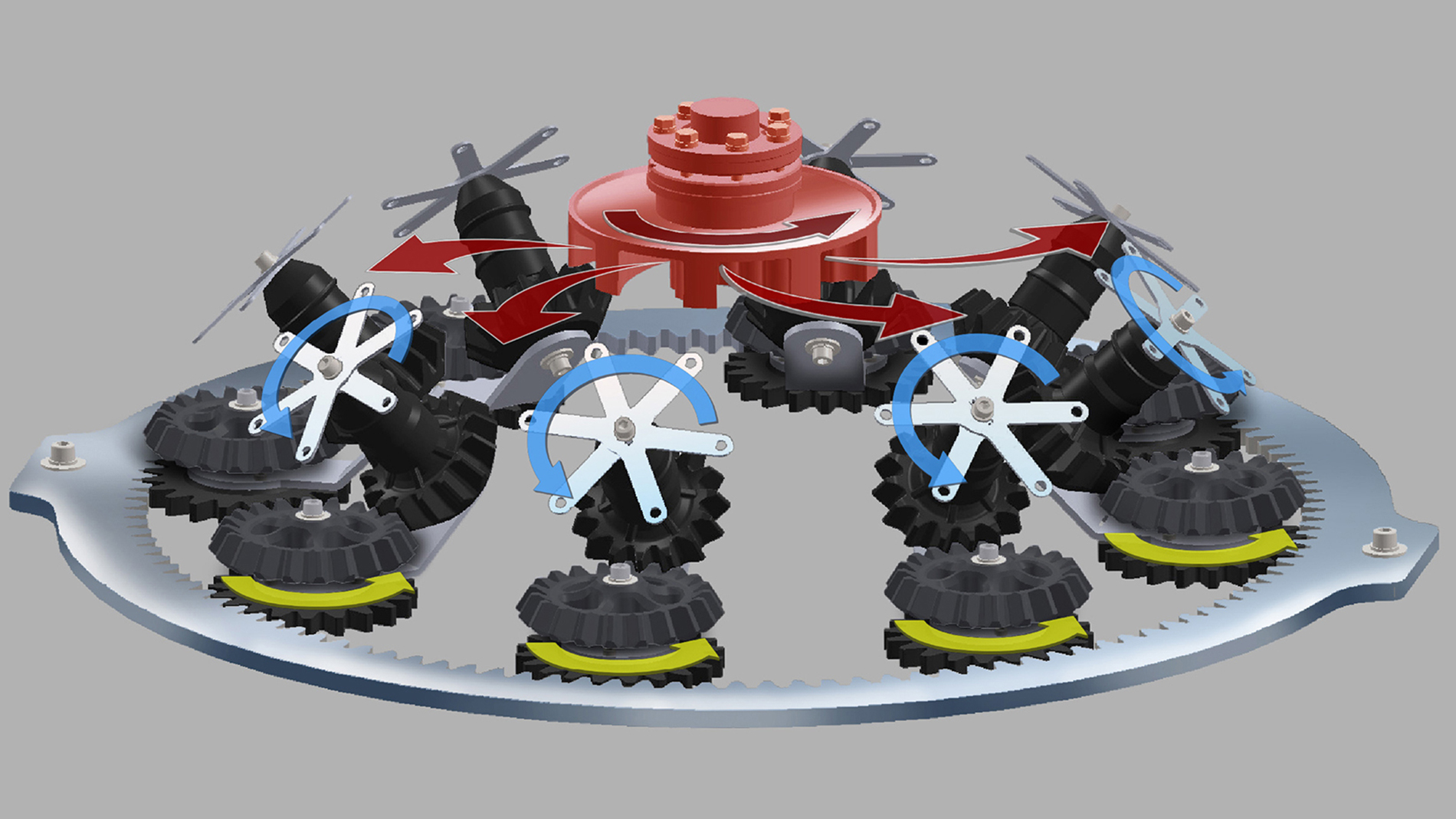

BMF GmbH, a mechanical production company based in Grüna (near Chemnitz), Germany, is expanding its portfolio of automatic blasting systems with the Twister750. The “750” refers to the internal width and depth of unit’s compact blasting chamber. Compared to the established Twister, the new system is not only smaller, but also primarily aimed at the needs of smaller companies. With its simple operation, BMF says that the Twister750 presents a highly intriguing solution for the automatic blasting of many small components, especially for manufacturers and dental laboratories. Meanwhile, the Twister750 offers space for numerous components on a turntable with eight workpiece carriers, which rotate around the blast wheel on holding elements and are continuously processed on all sides by the blasting media. BMF developed its Smart Surface Control technology to enable precise programming of the optical and physical properties of surfaces. This allows the entire manufacturing process to be tailored to the desired surface quality. Here, AI-supported analysis of previously blasted reference workpieces helps to determine the ideal blasting parameters.

BMF at Formnext 2025: Hall 11.0, Booth B30

Images: BMF

Depureco: Safe disposal of reactive powders

The new EcoBull AM and TB AM industrial vacuum cleaners from Depureco can be seamlessly integrated into PBF 3D printers to ensure safe, efficient extraction of reactive metal powders in Additive Manufacturing. With ATEX-certified side channel blowers, they feature explosion-proof technology. Once powder is vacuumed, it is directed through a submerged nozzle into an inert liquid bath inside a container. Here, a dual-stage filtration system consisting of a metal grid filter and a nylon filter separates the powder from the liquid, preparing it for safe disposal. The inert liquid can then be easily drained through a gravity discharge tap positioned at the base of the container.

Depureco Industrial Vacuums at Formnext 2025: Hall 11.1, Booth A11

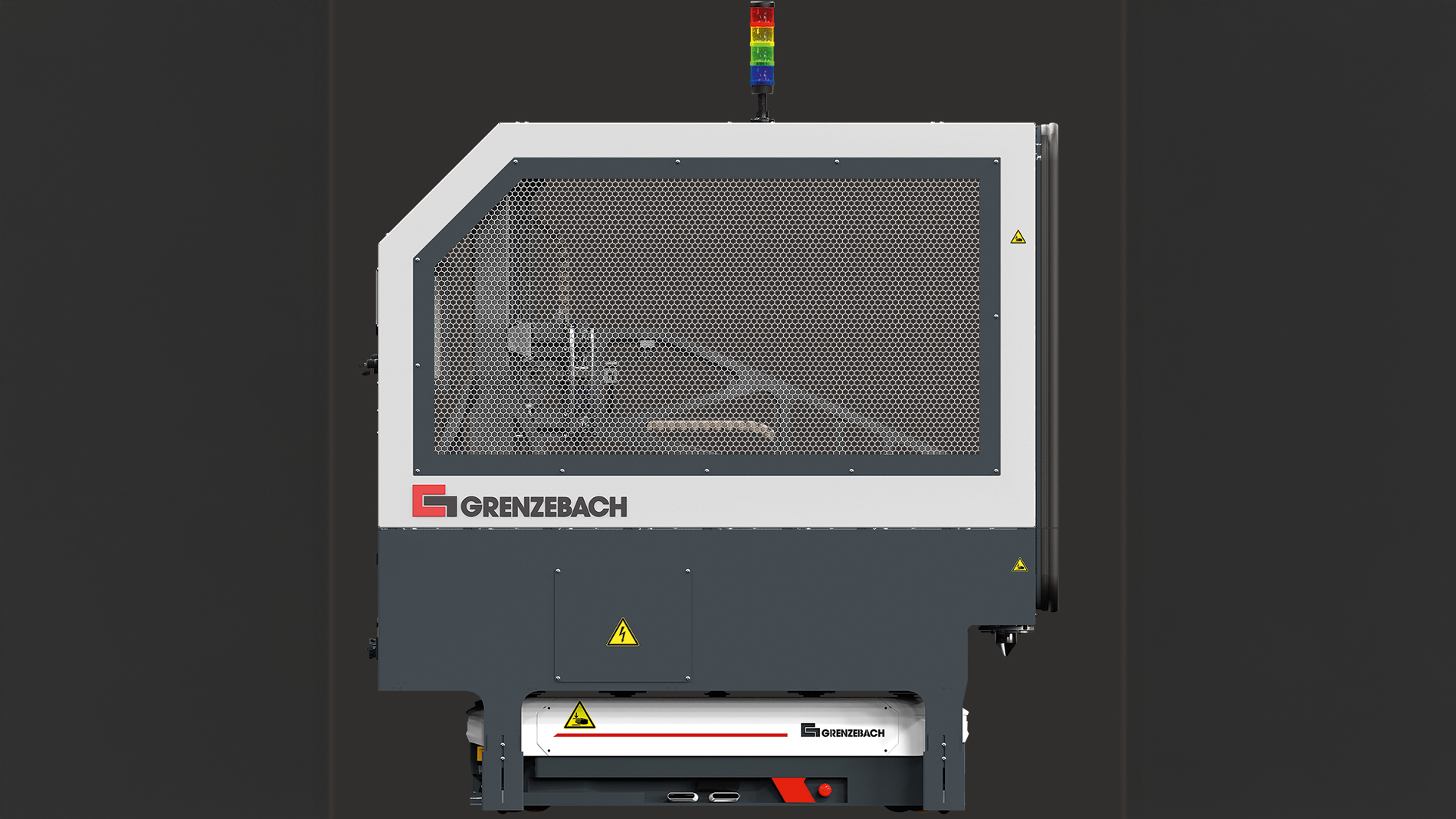

Grenzebach: Automatic loading and unloading

Grenzebach, a specialist in automation solutions for industrial processes, is launching two new solutions for Additive Manufacturing. The upgraded Dual Setup Station makes it possible to fully automate loading and unloading of metal 3D printers and start of new build jobs directly. Grenzebach’s portfolio is also complemented by a new transport container that ensures automated replacement of the build platform and can be flexibly integrated into existing manufacturing environments.

Grenzebach at Formnext 2025: Hall 11.1, Booth D63

MR Chemie: For clean build plates

With the new Reflecon Build Plate Cleaner, MR Chemie GmbH is launching a specially developed cleaning solution that thoroughly and gently removes residues from pressure beds. With this product, MR Chemie is expanding its Reflecon portfolio, which includes 3D scanning technology and solutions for 3D printing. As a ready-to-spray application, Reflecon Build Plate Cleaner allows variable spray-pressure dosing. According to MR Chemie, it also offers a short drying time. Regular cleaning is said to contribute to the longevity of the printing bed surface, as well.

MR Chemie at Formnext 2025: Hall 12.1, Booth F41

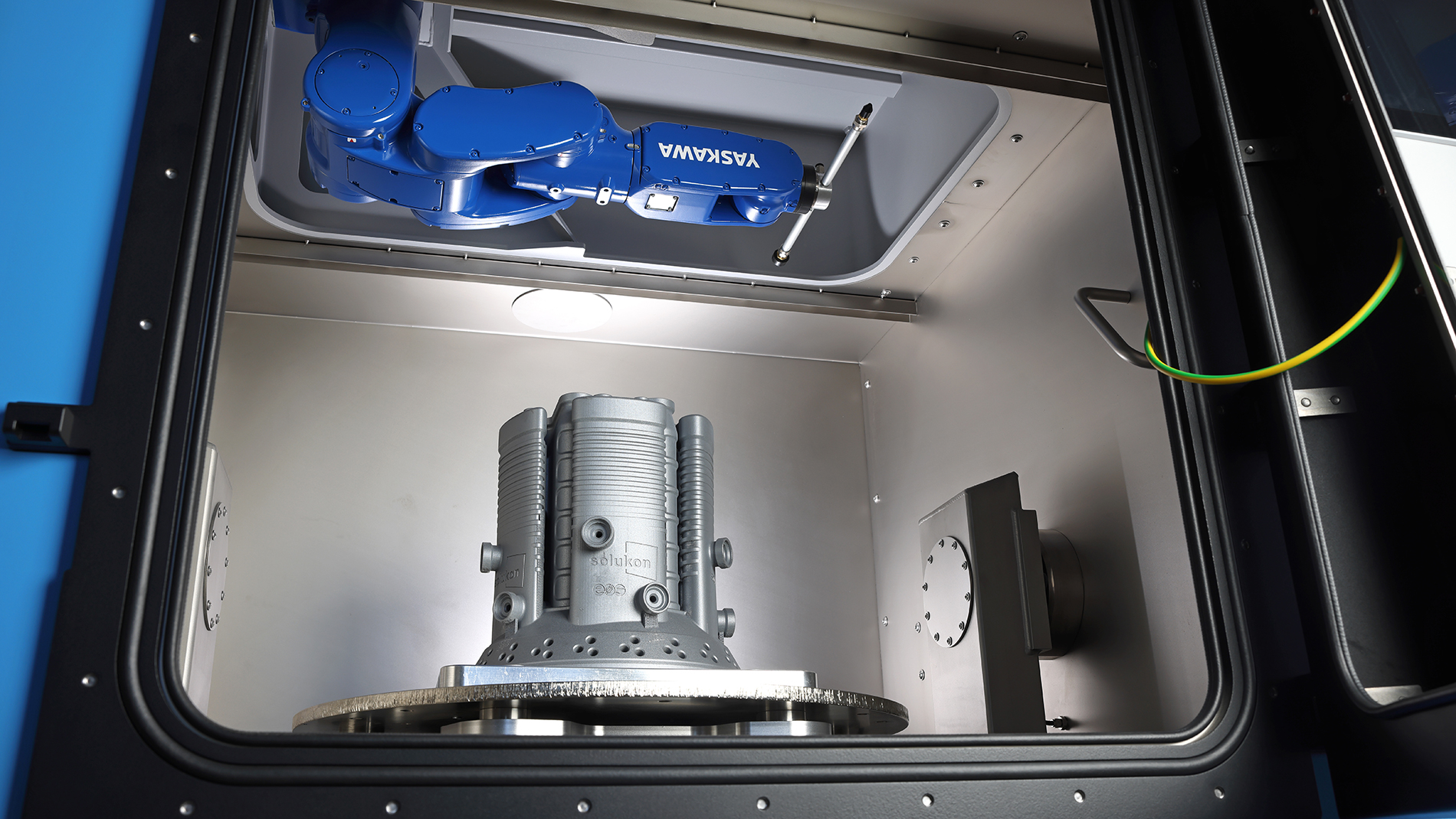

Solukon: Robot-integrated depowdering

To mark its 10th anniversary, Solukon is presenting a special version of its SFM-AT800 depowdering system with component transfer and robot finishing. The process flow of the machine concept is as follows: A transport trolley from Grenzebach transports the component to the Solukon system, which is equipped with an automated front door. After the component is fixed in place using an automatic zero-point clamping system, the depowdering process begins. An integrated robot from Yaskawa finishes the component (in this case by blowing away powder residue on and in the component). In addition to the SFM-AT800-S, Solukon is set to show off its SFM-AT350-E system, which depowders medium-sized components quietly and gently using ultrasonic excitation.

Solukon at Formnext 2025: Hall 12.0, Booth D71