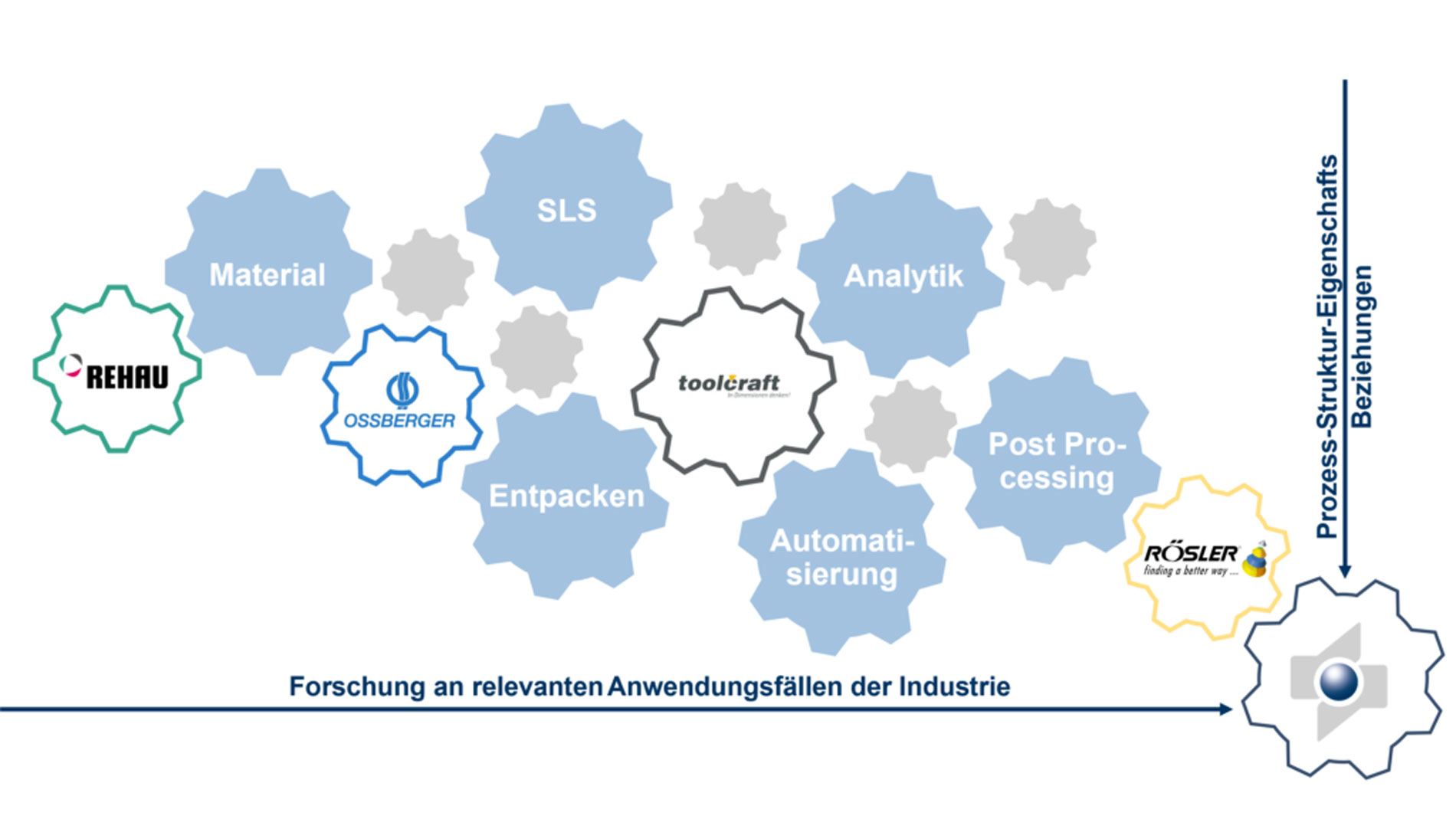

The partners involved are Neue Materialien Bayreuth, Rehau Industries, Toolcraft, Ossberger, and Rösler Oberflächentechnik. Selective laser sintering (SLS) enables the efficient production of high-quality plastic components in large quantities. In addition to the actual printing process, however, downstream steps such as coarse de-powdering and surface finishing are crucial to component quality. Until now, these steps have often been carried out manually, which increases costs, limits reproducibility, and makes industrial use more difficult.

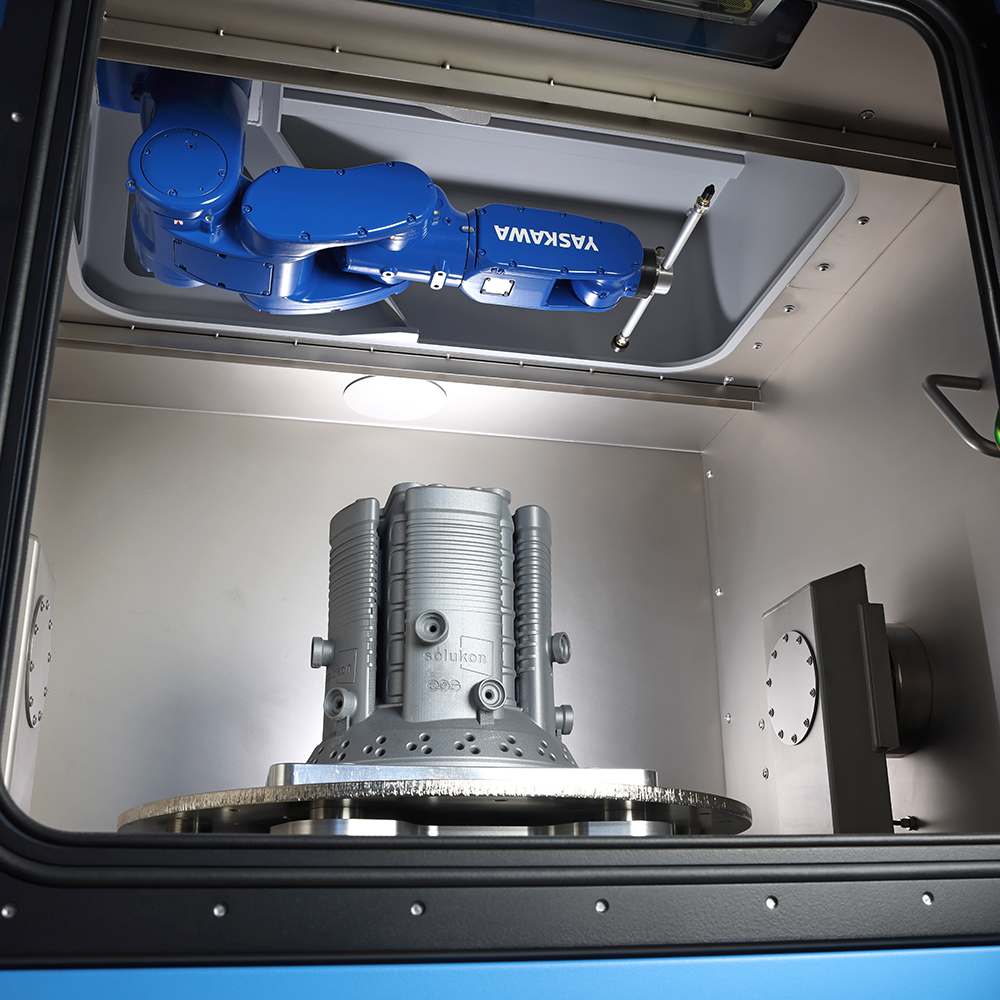

To reduce costs and the time required for component production while increasing quality, the partners in wiseON are investigating the automation and networking of the entire post-processing chain. Inline quality assurance systems are also being integrated. The collection and networking of relevant machine data is to result in a comprehensive process analysis that reveals optimization potential and makes Additive Manufacturing more efficient.

In particular, the project is focusing on the reusability of powder, which is a key factor in sustainable and cost-efficient production. Various SLS powders are therefore being examined to evaluate their processability after repeated recycling. Critical material properties such as particle size distribution and flowability are being continuously measured and analyzed with regard to their impact on the printing process.