29 June 2023, by Thomas Masuch

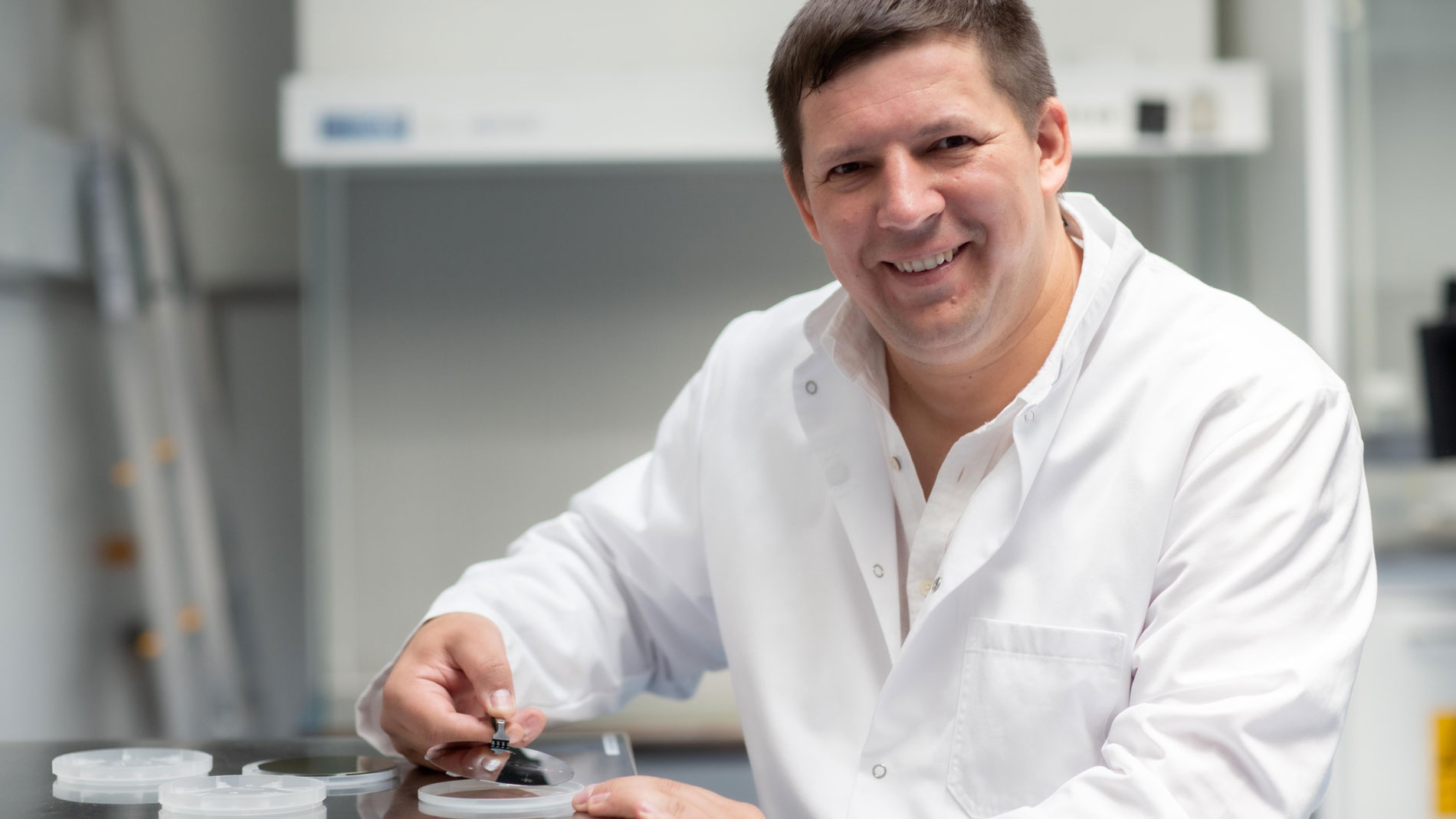

The young Danish company Atlant 3D has big plans with 3D printing of tiny particles at the atomic level. The company, founded five years ago by Maksym Plakhotnyuk and two partners and winner of the 2021 Formnext Start-up Challenge, wants to shake up the semiconductor industry.

At the beginning of this year, the company moved into a new building, where it now also has more space for further growth: Atlant 3D wants to grow to 30 employees by the end of 2023 ¬– that would mean doubling in size within one year. “Above all, we want to strengthen ourselves further in the area of engineering and development,” Dr. Plakhotnyuk explains. Such rapid growth is also made possible by a €15 million financing round that the company closed in 2022.

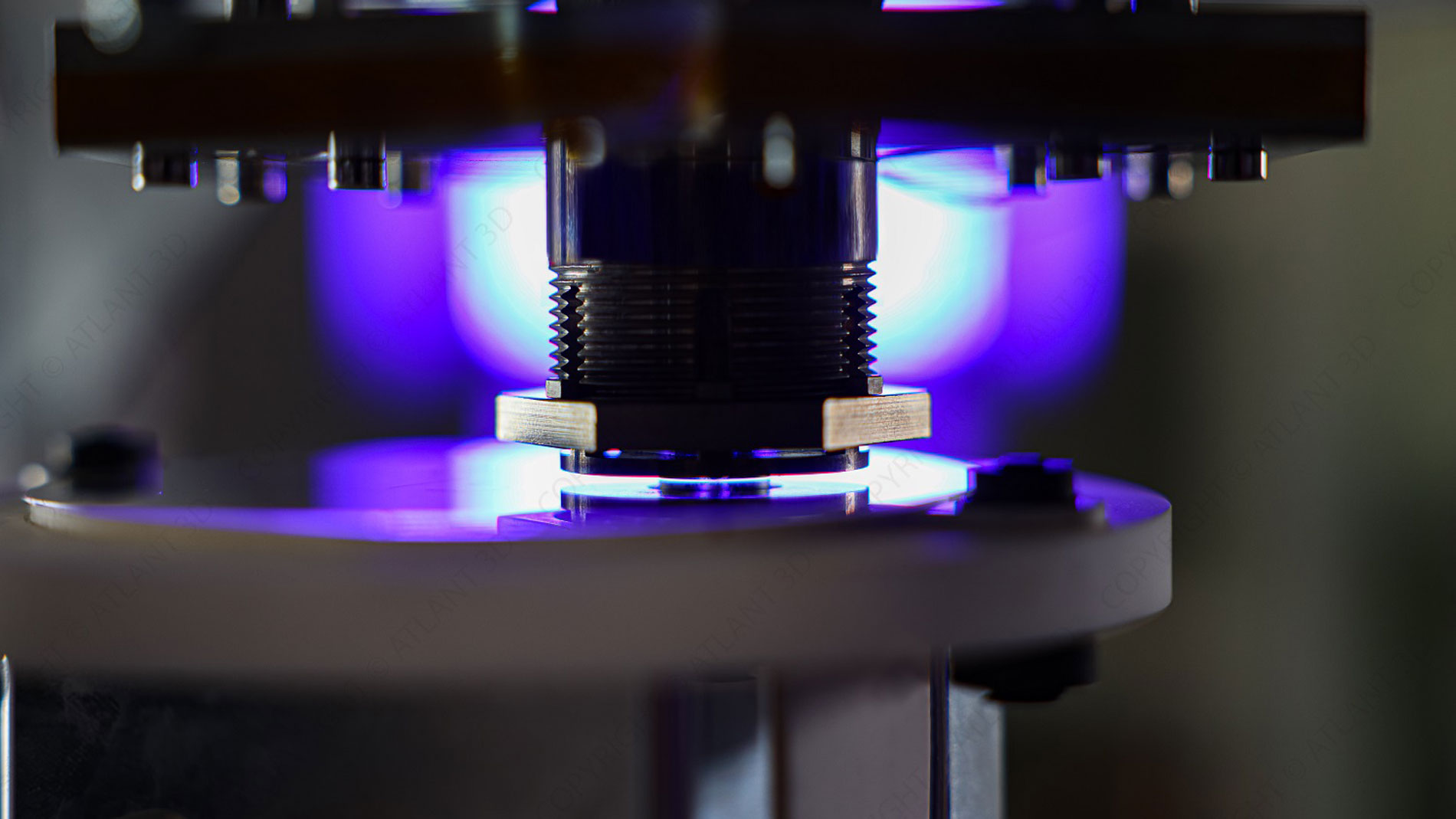

The company now has three systems for microprocessing in its portfolio: The Nanofabricator machines can produce and process parts with diameters of up to 150 mm and 6 materials simultaneously. The Nanofabricator LiteTM was developed by Atlant 3D according to strict NASA specifications and tested with NASA to enable microfabrication under micro-gravity and zero-gravity conditions. A total of three systems have already been delivered. In addition to NASA, customers and partners include ESA, STMicroelectronics and others.

Shortening the process chain

With its systems, Atlant 3D is particularly targeting manufacturers of semiconductors for optical lenses, filters, sensors and other high-tech applications, for example. “Two challenges arise in the classic production of semiconductors: The surfaces are usually polished, and it is very difficult to combine different materials,” Plakhotnyuk said. "We can solve both challenges with 3D printing. We make complex structures possible, shortening the process chain for manufacturing prototypes or finished components."

Atlant 3D was founded by Maksym Plakhotnyuk in 2018. The Nanofabricator LiteTM was developed by Atlant 3D according to strict NASA specifications. Images: Atlant 3D

Winning the Start-up Challenge also had an important influence on the company's successful development: “We exhibited our first prototype at Formnext a year and a half ago and met very interesting people – investors or suppliers, for example,” Plakhotnyuk recalls. And contact with Addifab, another Copenhagen-based startup that has since become part of Nexa 3D, enabled Atlant 3D to move to its new headquarters.

The company has already planned the next big step: A new system will soon be launched that will not only be able to 3D print metals at the atomic level, as before, but also nitrates and other non-metallic materials. "This is the Holy Grail, so to speak, in the manufacture of semiconductors,” Plakhotnyuk enthuses. This could then be used to apply 1000 times 1000 sensors to a chip, creating an "inorganic neural network that can be the future of artificial intelligence.”

MOHR INFORMATION:

Tags

- Additive Manufacturing

- Aviation and aerospace