Text: Thomas Masuch, 1 December 2023

Exciting prints, extraordinary designs, new ground-breaking technologies – all this has been a hallmark of Formnext since its very first edition. Nowhere else can you get such a great perspective on the future of additive manufacturing. Which trends will influence industrial manufacturing in the coming years? Which applications will change, and where will AM unleash its disruptive power? Meanwhile, Formnext itself has also evolved over the past few years as additive manufacturing has come of age.

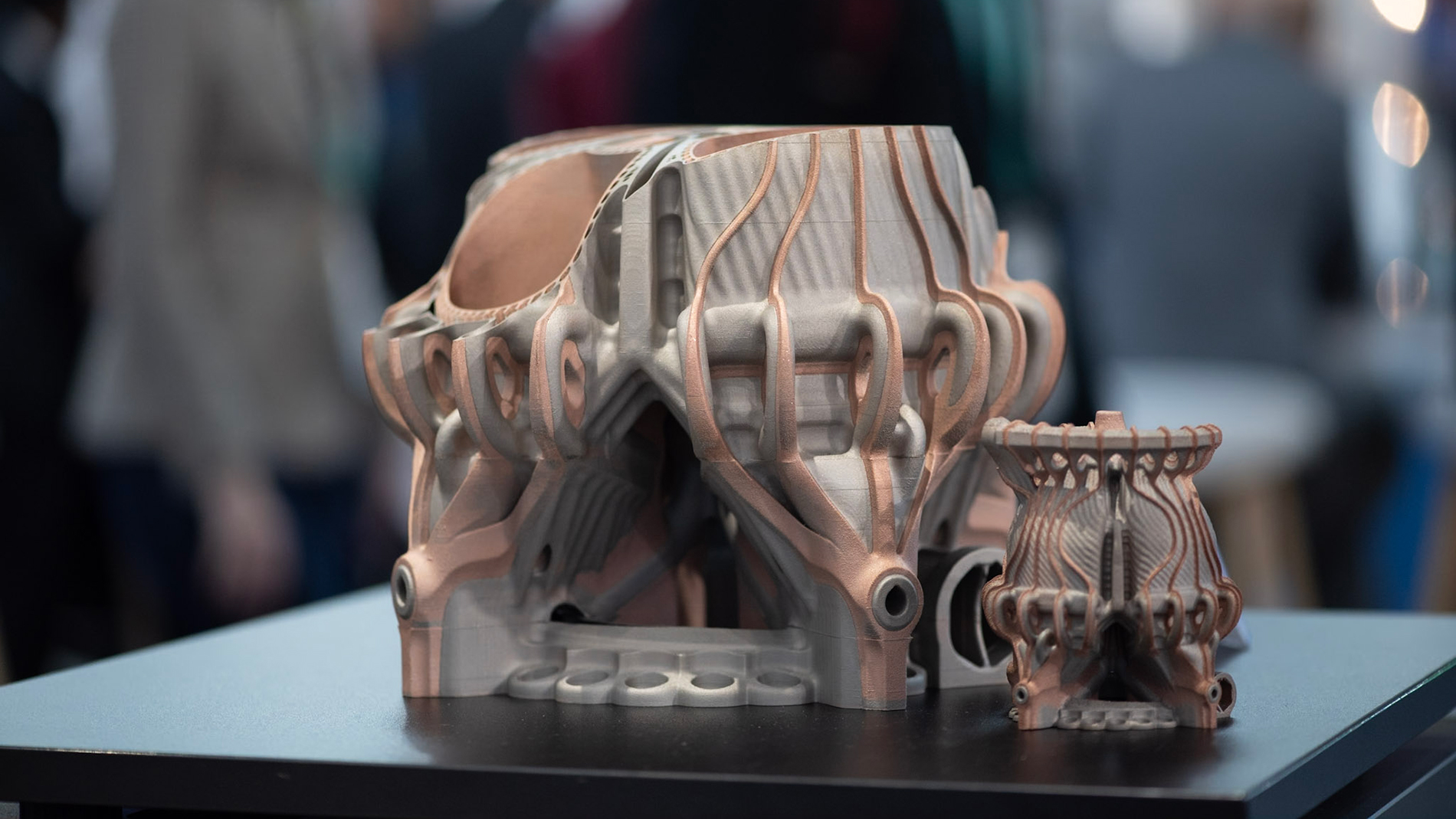

For the trade fair’s exhibitors and visitors, one specific question seems to be increasingly coming to the fore: How can money be made with AM? At Formnext 2023, even more specific applications were on display, ranging from medicine, textiles, and automotive components to heavy impellers for power plant generators. Many innovations also focused on greater cost-effectiveness and more efficient AM production. That said, eye-catching exhibits were still to be found at Formnext, including three Formula One racing cars. Motorsport remains an important sales market for AM manufacturers, after all, as well as an industry that continues to drive development forward.

Larger machines and larger parts - one of the trends at Formnext 2023. Photos: Mesago

Automation and throughput

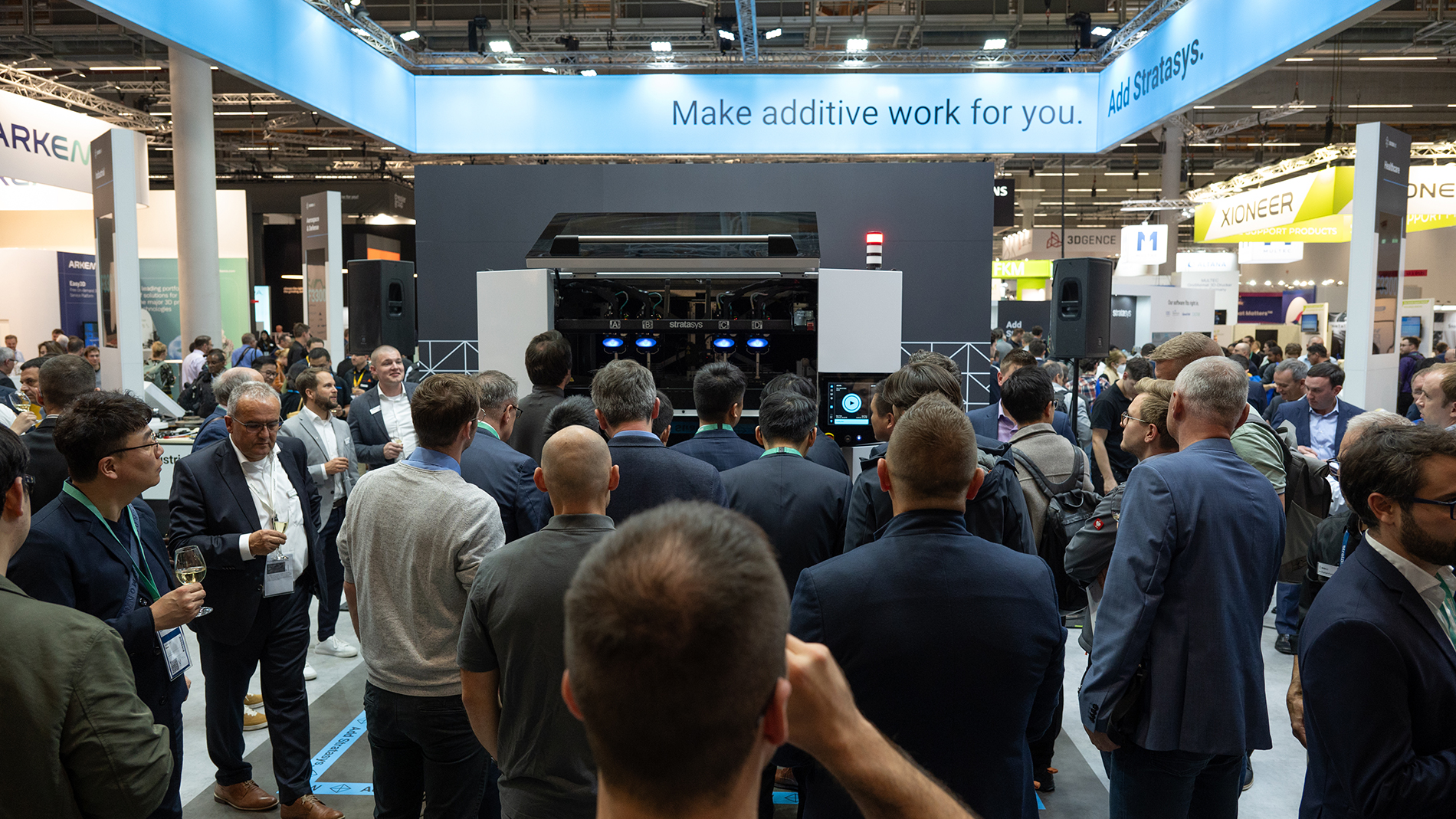

Two factors in particular can facilitate greater cost-effectiveness: automation and higher printing speeds. Almost all the major system providers now offer solutions for automation, while numerous smaller and specialized companies – 3D-Ceram, AM-Flow, Mosaic, and many others – also showcased software solutions for the entire process chain. Higher printing speeds were also one of the key features in numerous products that were launched at Formnext 2023. Industry giant Stratasys, for example, is promising twice the throughput of conventional FDM printers with its new F3300.

Materials driving new applications

One of the most important drivers of new applications are materials, which is another area where Formnext 2023 had a lot to offer. Both established system providers such as 3D Systems and specialized material providers like Henkel presented too many new developments to list here. In addition, traditional material manufacturers are increasingly discovering additive manufacturing as an exciting sales market. The German company Cunova, for instance, presented its copper powders for the first time at Formnext. “We realized here that a completely new market is opening up for us in additive manufacturing and now see even more potential to fully enter the supply chain as a powder supplier,” Robin Bappert and Christof Dratner were pleased to report. Meanwhile, 3D printing with pellets seems to be gaining more and more ground. One of the industry’s leaders, Arburg, developed a technology for this years ago and successfully established it on the market with its Freeformer. At Formnext 2023, significantly more companies had pellet printers in their product range, with Bosch Industrial Additive Manufacturing presenting its own new pellet-printing technology. One material supplier noted that pellets could potentially overtake filament in the future.

New materials are leading to an increasing number of applications. At Formnext, more and more multi-material printing applications were on display. Images: Mesago

Cooperations

There’s no such thing as an unlimited budget, even in additive manufacturing. That’s one of the reasons why the conviction that certain new developments can be better shouldered together seems to be gaining traction; the costs can then be spread around and joint synergies exploited. A number of new cooperation projects were thus presented at Formnext. The most prominent of these was certainly the AM I Navigator (Additive Manufacturing Industrialization Navigator) initiative, which aims to guide AM users through the increasingly complex AM landscape with tailored advice. The project is a collaboration among Siemens, DyeMansion, BASF Forward AM, EOS, and HP. There have also been exciting developments on a smaller scale, however, such as the cooperation agreement between Fraunhofer IGCV and Nikon SLM Solutions AG, which want to strengthen their collaboration in the multi-material sector. Post-processing specialist Rösler also announced partnerships with EOS, FKM Additive Manufacturing, and Shapeways.

Ever larger, ever smaller

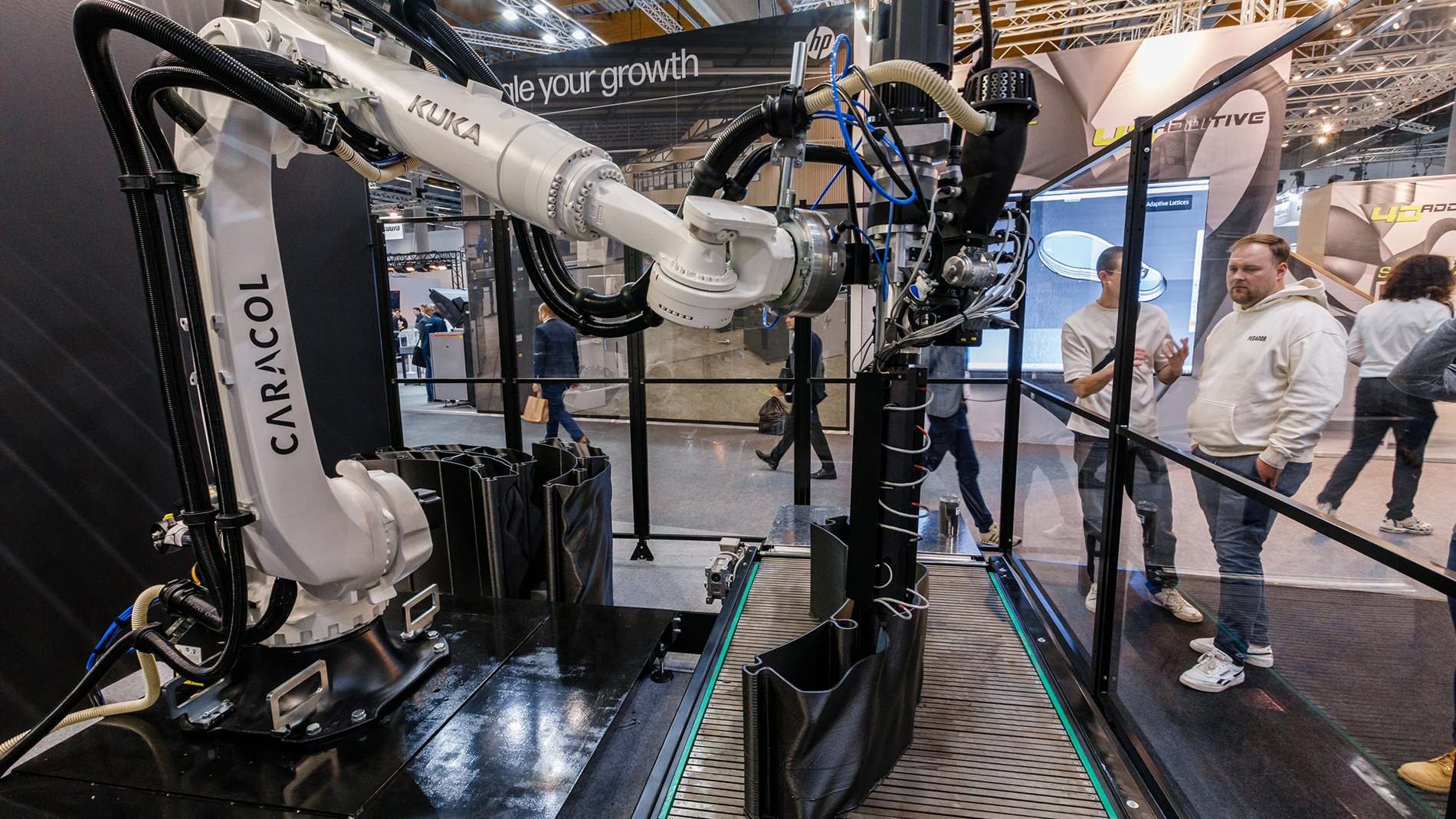

In terms of size, the trend that had already become apparent at previous editions of Formnext continues: Things are getting bigger and bigger. In metal printing, AMCM, Eplus3D, InssTek, MX3D, and others exhibited enormous machines capable of creating components weighing several tons. These considerable dimensions are placing entirely new demands on simulation and construction job monitoring, and numerous companies (such as Oqton and 1000 Kelvin) presented appropriate solutions this year. After all, misprints at this scale are not only annoying – they really hurt business. Meanwhile, the plastics sector is witnessing similar growth. The machine on which CMS printed voluminous components live at Formnext was certainly a real eye-catcher. Many other companies, including WASP and Caracol, demonstrated the flexibility and speed of their technology live at the trade fair, often with robot-based 3D printers.

At the other end of the spectrum, there was also a lot to see at Formnext in the nano sector. In addition to market leader Nano Dimension, more and more companies are establishing themselves in this segment (such as 3D MicroPrint). They showcased an even wider range of applications this year, from 3D-printed electronics and tiny screws for the production of cell phones to small molds for injection molding and tiny components for space travel. In the future, the latter will ensure that satellites can be built significantly smaller, and therefore lighter.

Real eye-catchers and spectacular designs from numerous industrial sectors: from construction to textiles to Formula One. Images: Mesago

Medical, aerospace, automotive, and more

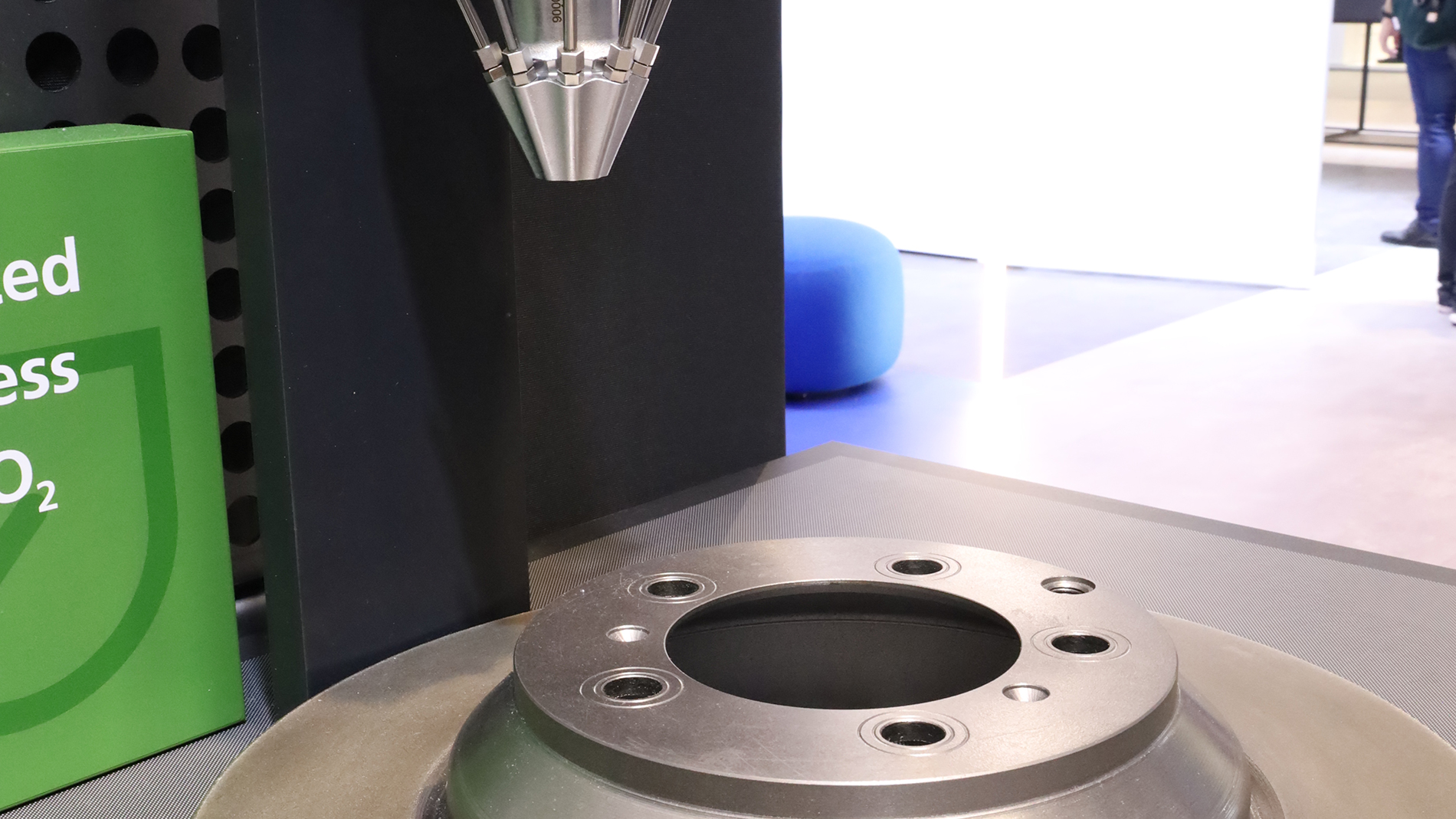

Thousands of applications on display at Formnext 2023 gave the impression that the medical and aerospace sectors are still the most important drivers of the industry and its technical development. This was confirmed not only at the booths of the major system providers, but also by the joint Fraunhofer booths and those of other research institutes. Other interesting developments could be seen in the field of textiles from Stratasys, Mosaic and more. Interestingly, companies such as Trumpf, Prima Additive, and the material supplier Mimete displayed brake discs (in some cases including corresponding coating technology) quite prominently at their booths. The topic is being hotly debated in the automotive industry at the moment: Manufacturers of cars, vans, buses, and trucks will be required to implement the new Euro 7 emissions standard by July 1, 2025, which also places new demands on brake disc coatings. Additive manufacturing offers an excellent means of meeting these challenges.

Medical technology is one of the key drivers of innovation in additive manufacturing. The topic of brake disk coating was also very prominent at Formnext. Images: Mesago (5); Thomas Masuch (1)

The topic of construction was also very prominent at Formnext. In addition to the established special showcase on the subject, Constructions-3D used its MaxiPrinter to create the type of concrete structures used in building houses on a large area. The French company was just one of a number of exhibitors that presented solutions for this industry.

Tags

- Automotive

- Materials

- Additive Manufacturing

- Construction and architecture

- Medical technology

- Research and development