by Thomas Masuch

The team at AdditiveXperts could hardly have chosen a more difficult time to get their endeavor off the ground: About a year ago, the young Austrian company launched directly into the Covid-19 crisis. "That made our development more difficult at first, but we had a good network that we could use," reports co-founder and managing director Alexander Aigner.

Now the start-up, which specializes primarily in the development of new materials for Additive Manufacturing, wants to hit the ground running at Formnext in Frankfurt. "Formnext is a must-attend event for us," Aigner affirms. "While online meetings are all well and good, trade shows are very important – especially when it comes to gaining new customers. Real encounters are simply more sustainable." He acknowledges having collaborated intensively with others in the digital space during the pandemic. "You can handle things technically there, but if you want to build business relationships, personality plays a big role, and that only works in real life."

Alloy design and process parameters

In developing new AM materials, AdditiveXperts works closely with powder manufacturers. This results in new alloy designs for which process parameters for the LPBF process are also created after atomization. In this way, the company recently developed a new high-temperature-resistant steel that supports application environments beyond 1,100°C.

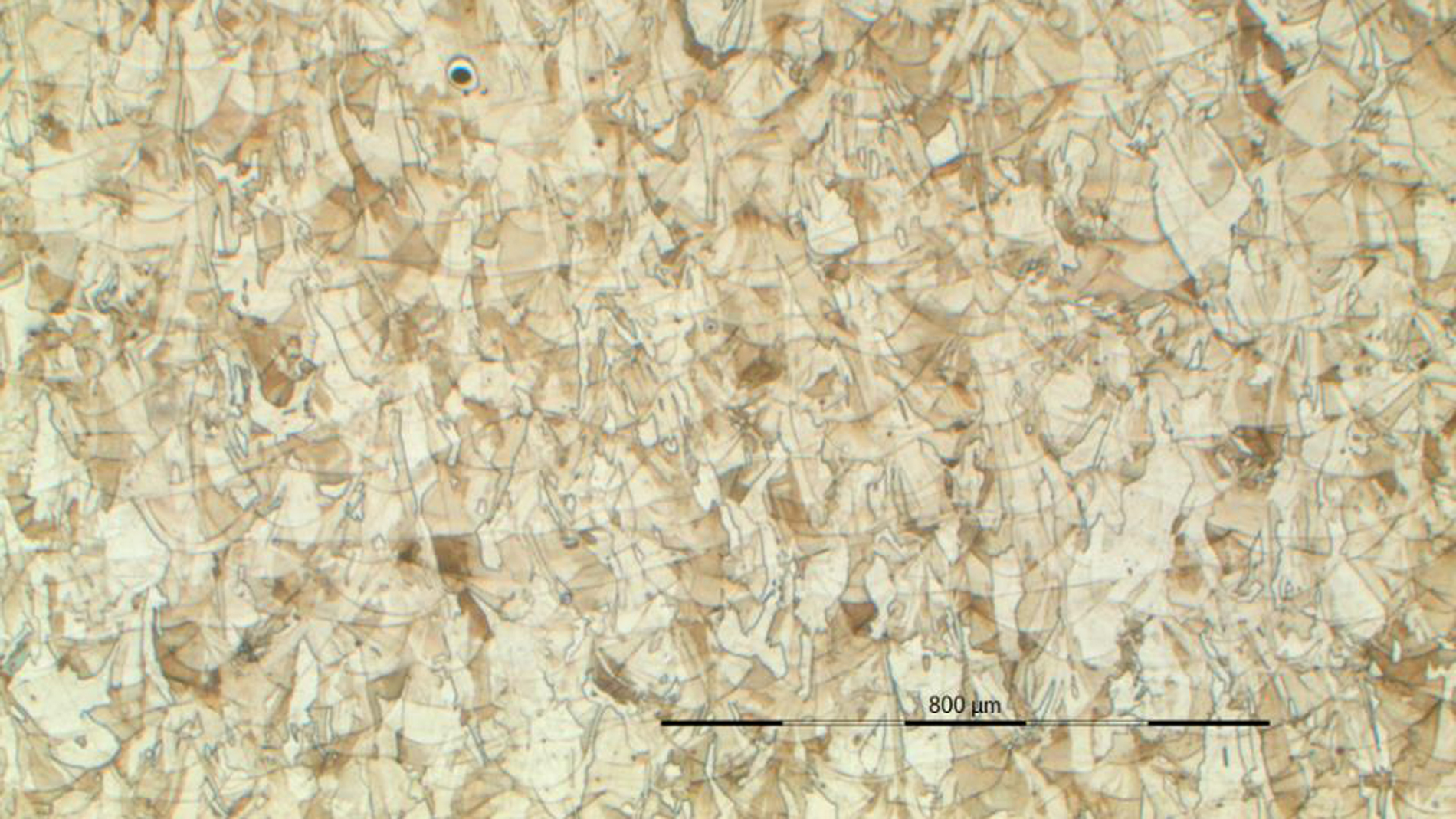

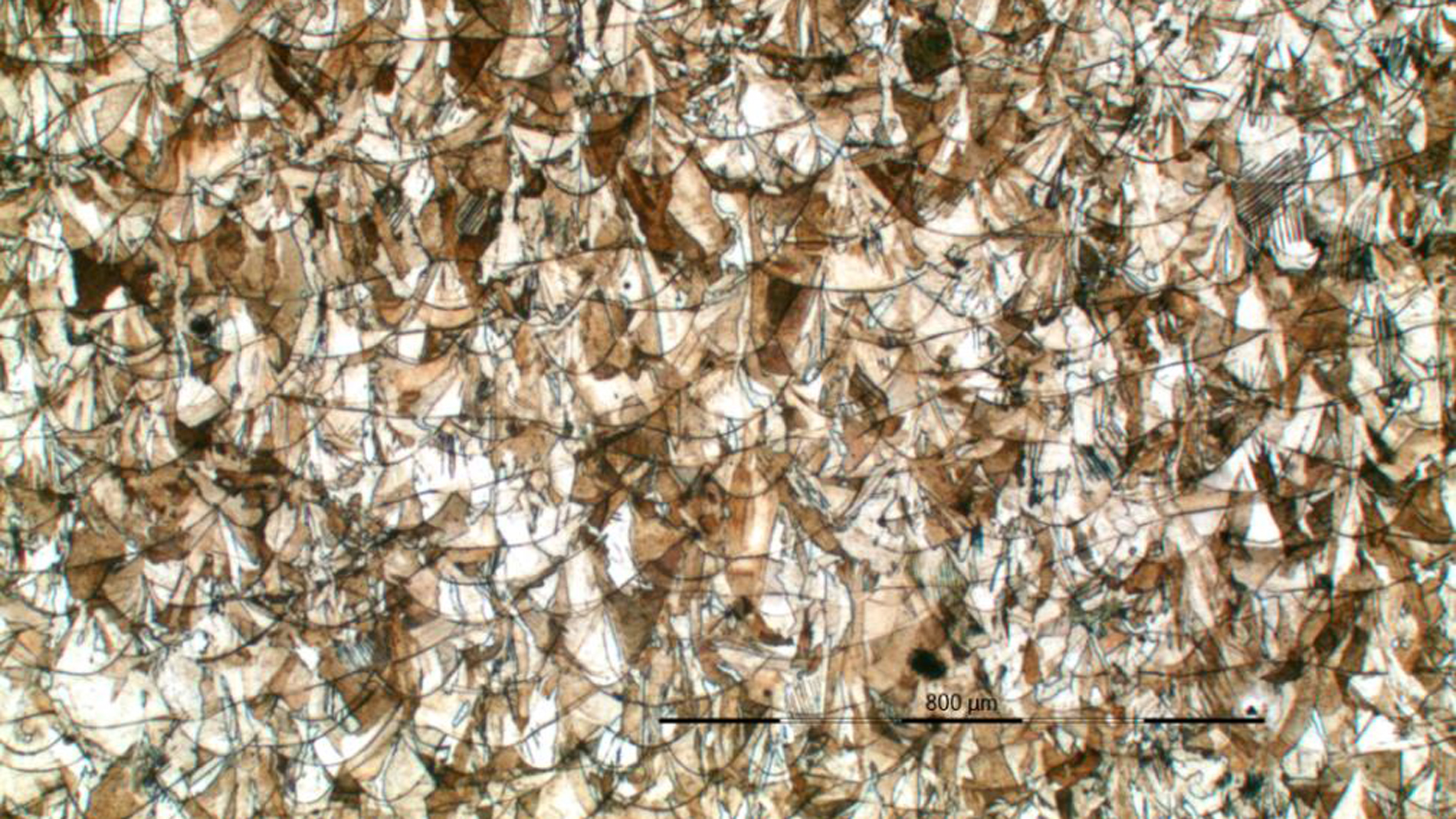

"When generating the process parameters, we made sure that we not only achieved component densities greater than 99.95 percent, but also the ability to print the material 30 percent more productively than comparable alloys thanks to efficient process control," reports a pleased Alexander Aigner. For the steel, sections made in the company's own laboratory were examined with regard to their porosity and microstructure. In the future, AdditiveXperts plans to offer in-house tensile tests, hardness measurements, and notched bar impact tests, as well.

During the young company’s first-ever appearance as an exhibitor at Formnext, Aigner and his team also want to offer their expertise in design, engineering, and the implementation of AM technology. "I’m really looking forward to interacting with people in person again – including with new contacts who haven’t had have us on their radar yet," Aigner says.

AdditiveXperts at Formnext:

Hall 12.0, Booth B81K

FURTHER INFORMATION:

Tags

- Additive Manufacturing