Text: Thomas Masuch, 6 November 2024

New materials are an important driver in the development of additive manufacturing. This is because AM processes often require special powders or filaments. No wonder the AM industry eagerly awaits the new material developments presented at Formnext every year! Visitors will not be disappointed in 2024, either: in the field of metals, new alloys of molybdenum and aluminum will be presented. Both feature impressive special properties that will certainly broaden the range of AM applications even further in the future. Meanwhile, other exciting recent innovations are enabling companies to develop their own materials. And let's not forget the important topic of powder handling, where Formnext will also be presenting new developments.

Crack-free and ductile at high temperatures

At Formnext, Plansee is presenting MoC0.4, its new molybdenum alloy for Additive Manufacturing. MoC0.4 consists of more than 99.5% molybdenum. According to Plansee, this patented alloy exhibits high strength at both room and elevated temperatures, and also remains crack-free and ductile at high temperatures. MoC0.4 has similar properties to conventionally produced TZM (titanium-zirconium-molybdenum). Plansee will be exhibiting at Formnext together with Ceratizit, which is also part of the Austrian Plansee Group. Together, the two companies will be showcasing a wide range of Additive Manufacturing solutions using the refractory metals molybdenum and tungsten, as well as carbide.

Conductive, strong, and weldable

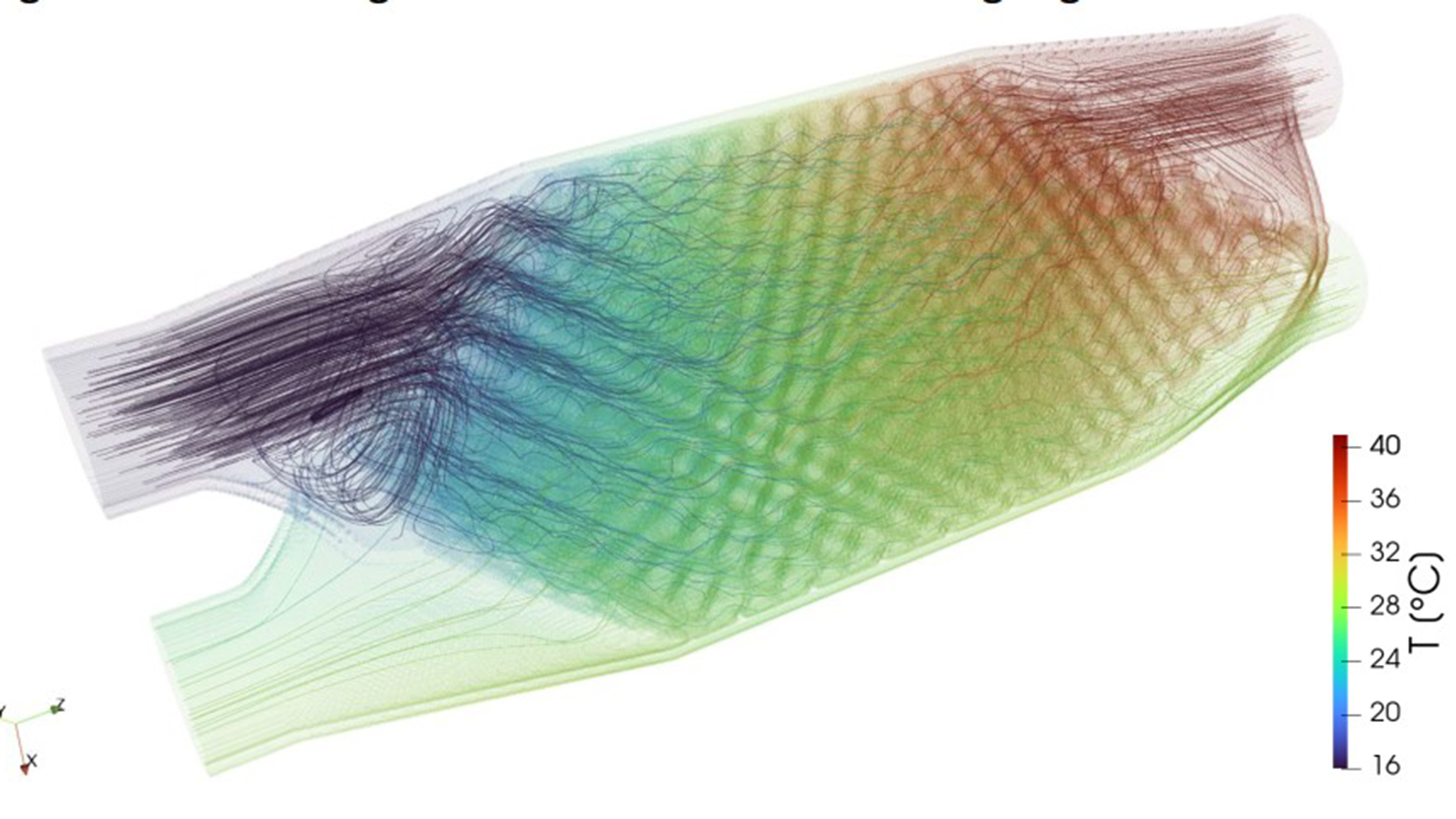

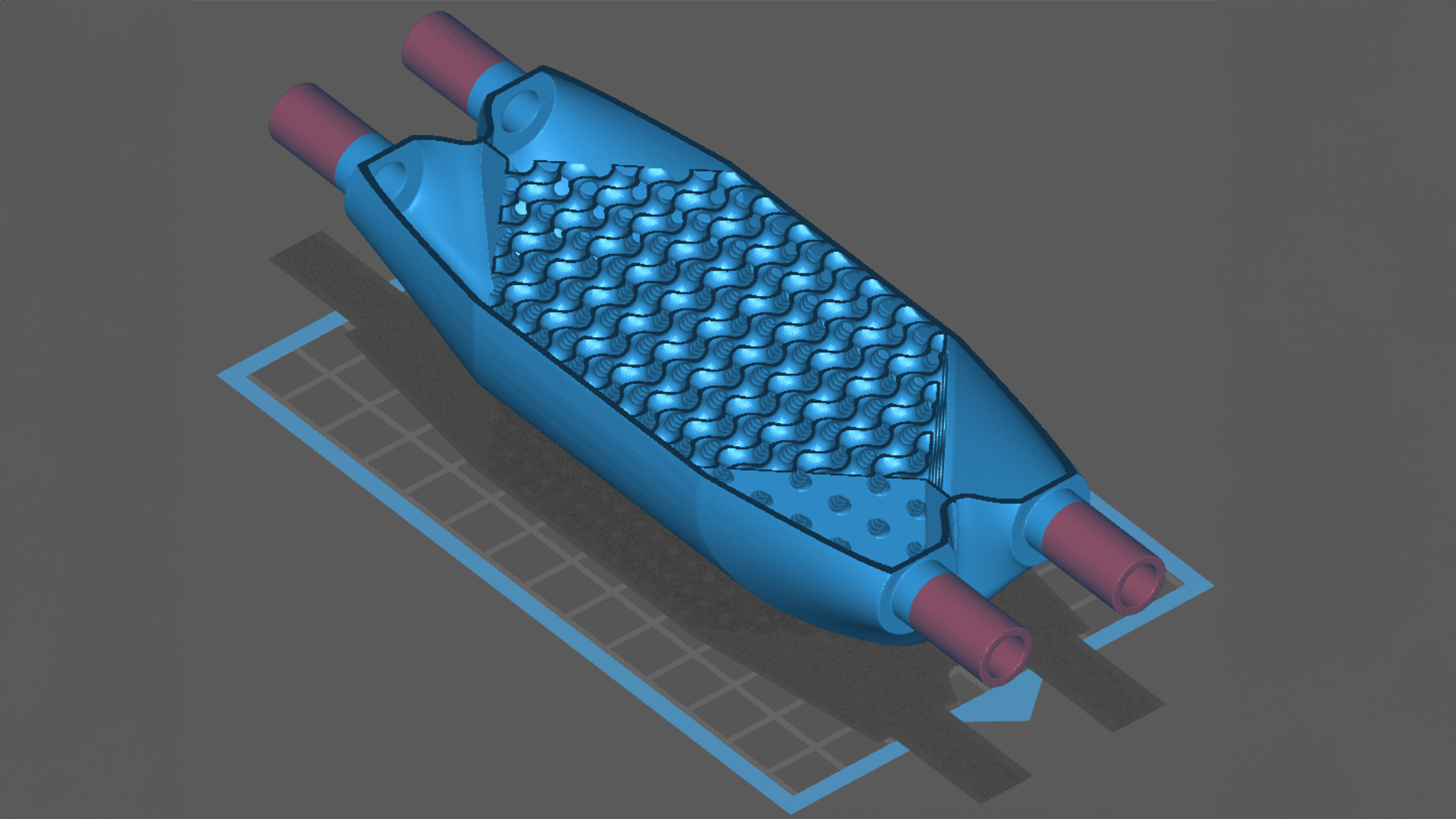

Feramic will showcase the industrial application of Aheadd CP1 aluminum, also known as Aluminum 320 (Feramic's own designation). According to Feramic, this new aluminum surpasses conventional alloys like AlSi10Mg in several key aspects. Its notable properties include excellent electrical and thermal conductivity, high strength, corrosion resistance, and the ability to be anodized. Aheadd CP1 is also highly weldable, which is a feature that sets it apart. Over the past 18 months, Feramic has worked diligently to optimize the material’s production parameters, ensuring that components made from CP1 can be produced with an ideal balance of cost and performance.

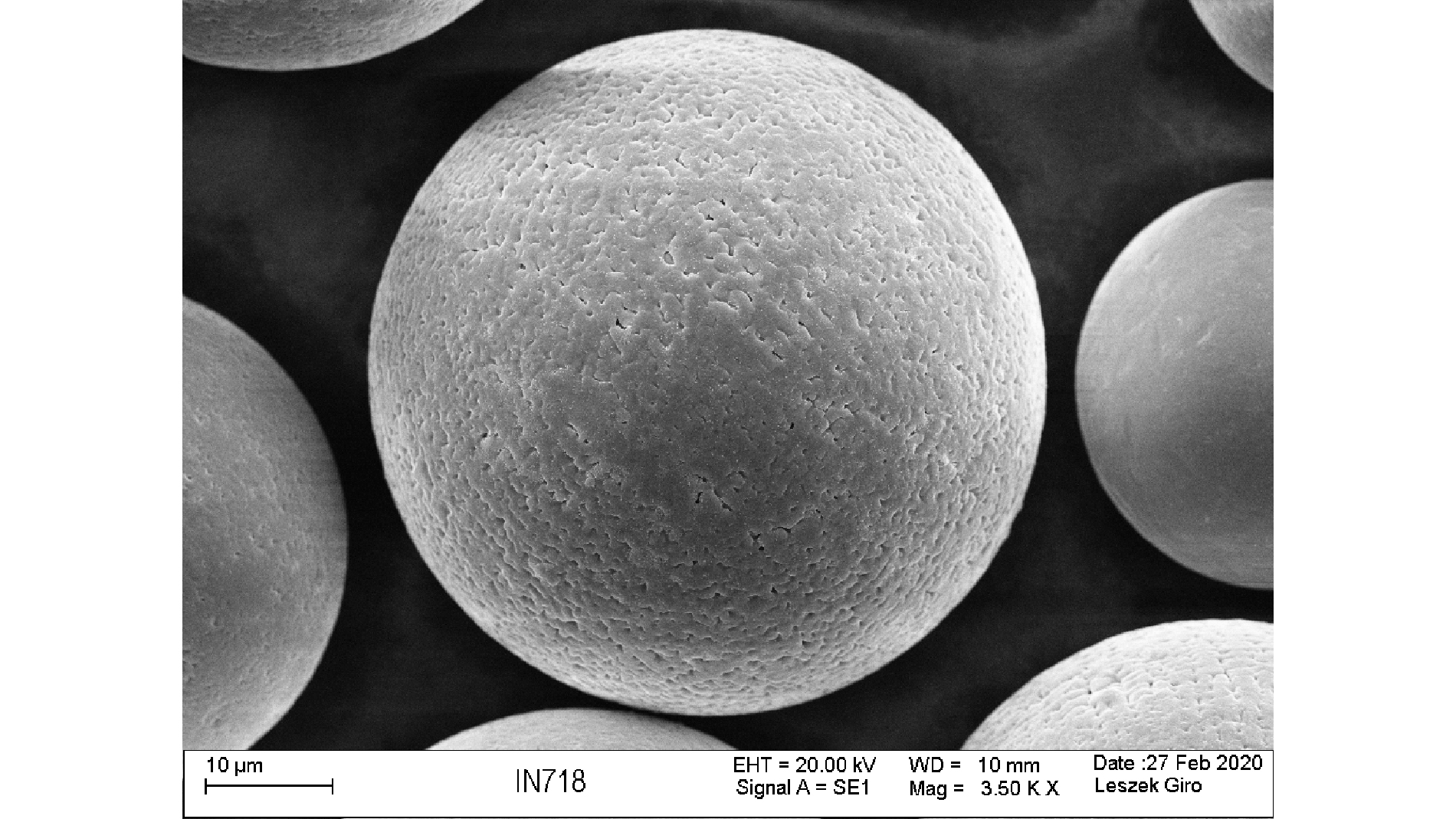

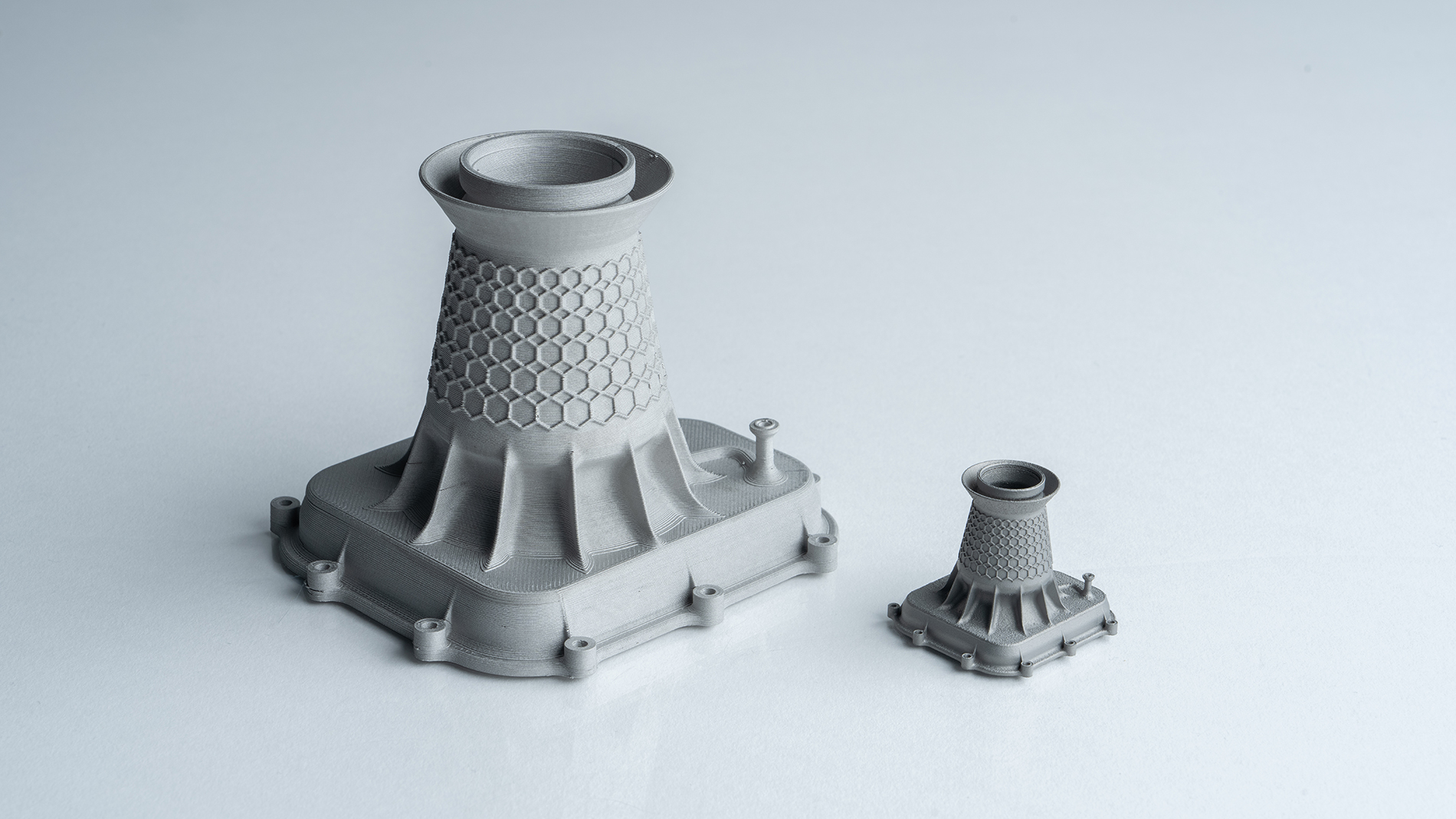

Full control over powder production

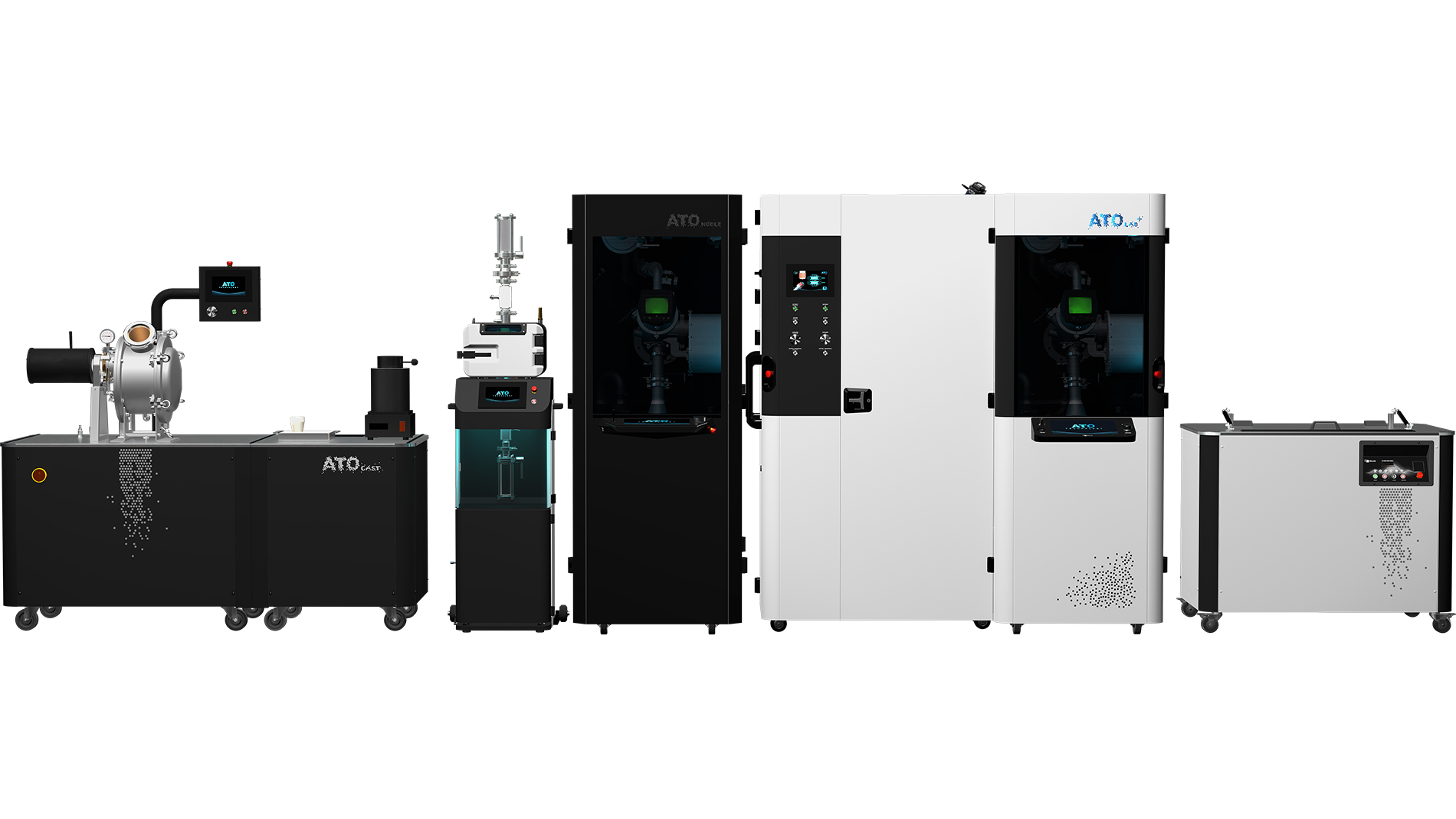

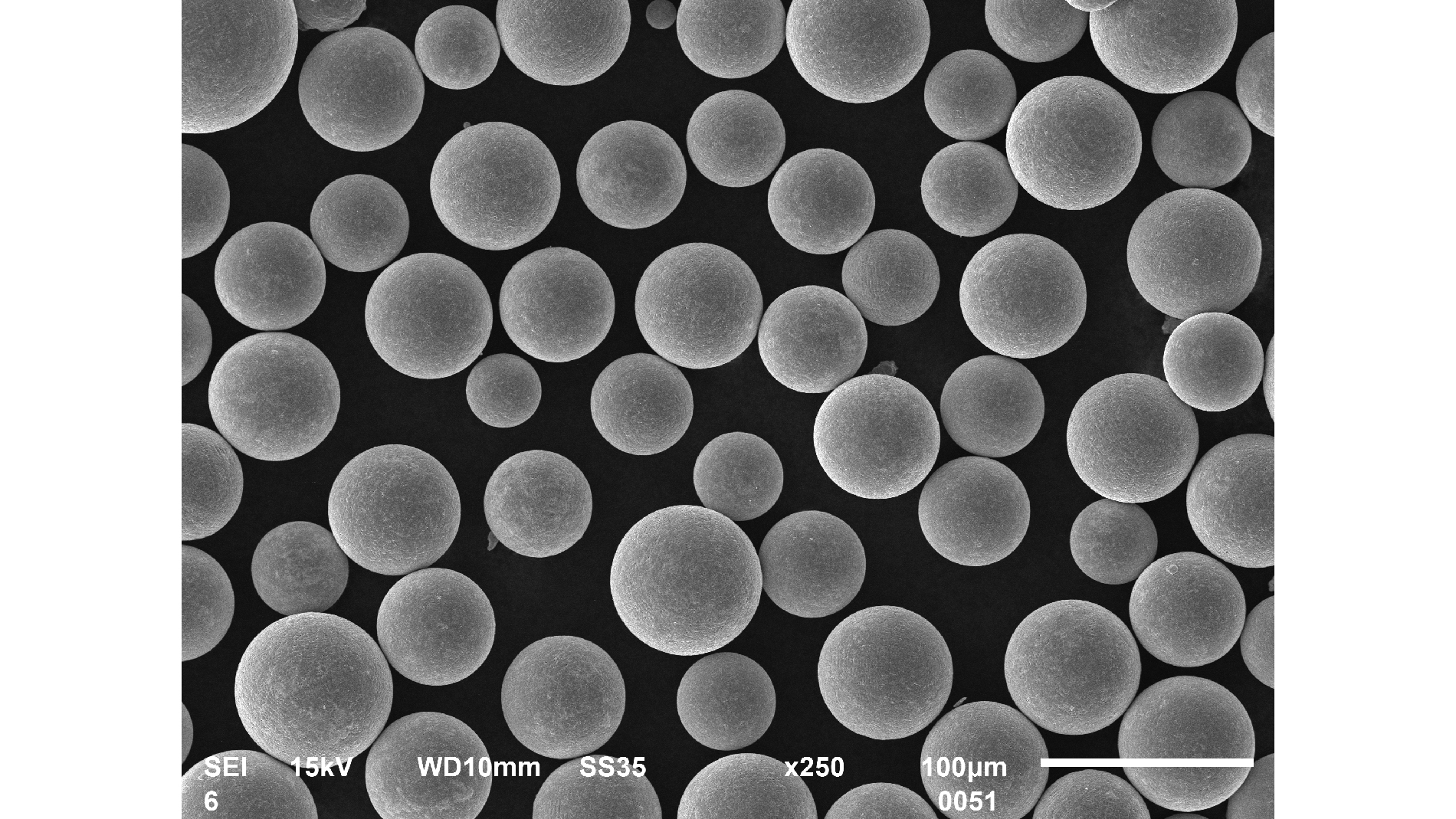

3D Lab, a metal atomization technology company, will be presenting its patented ultrasonic metal atomization solutions. This fully integrated suite, which includes ATO Lab Plus, ATO Noble, ATO Induction Melting System, ATO Sieve, ATO Cast, and ATO Clean – is designed to give customers complete control over their metal powder production processes. Developed for companies active in material engineering and additive manufacturing, these systems enable such firms to produce metal powder from their own alloys. This is meant to make innovations faster and more effective.

FURTHER INFORMATION:

You will find all the companies mentioned at Formnext 2024:

3D Lab: Hall 11.0, Booth B21

Feramic: Hall 12.1, Booth E19 (Swiss Pavilion)

Plansee and Ceratizit: Hall 11.1, Booth F19

Tags

- Materials