Text: Thomas Masuch, 25 October 2023

Attendees can look forward to plenty of world premieres in materials at this year’s Formnext, along with all the new applications these innovations are enabling.

Specialized materials are often the key to success in additive applications and business cases. The right powder or filament is frequently the only way to produce components cost-effectively in the necessary level of quality – and it’s the only way to tap into the full potential of AM, as well. It’s no wonder that companies in materials continue to develop new solutions every year; their revenues are also always increasing, after all. Formnext 2023 features numerous innovations that are designed for an array of applications that range from prototyping to hearing devices, further uses in medicine, and series production.

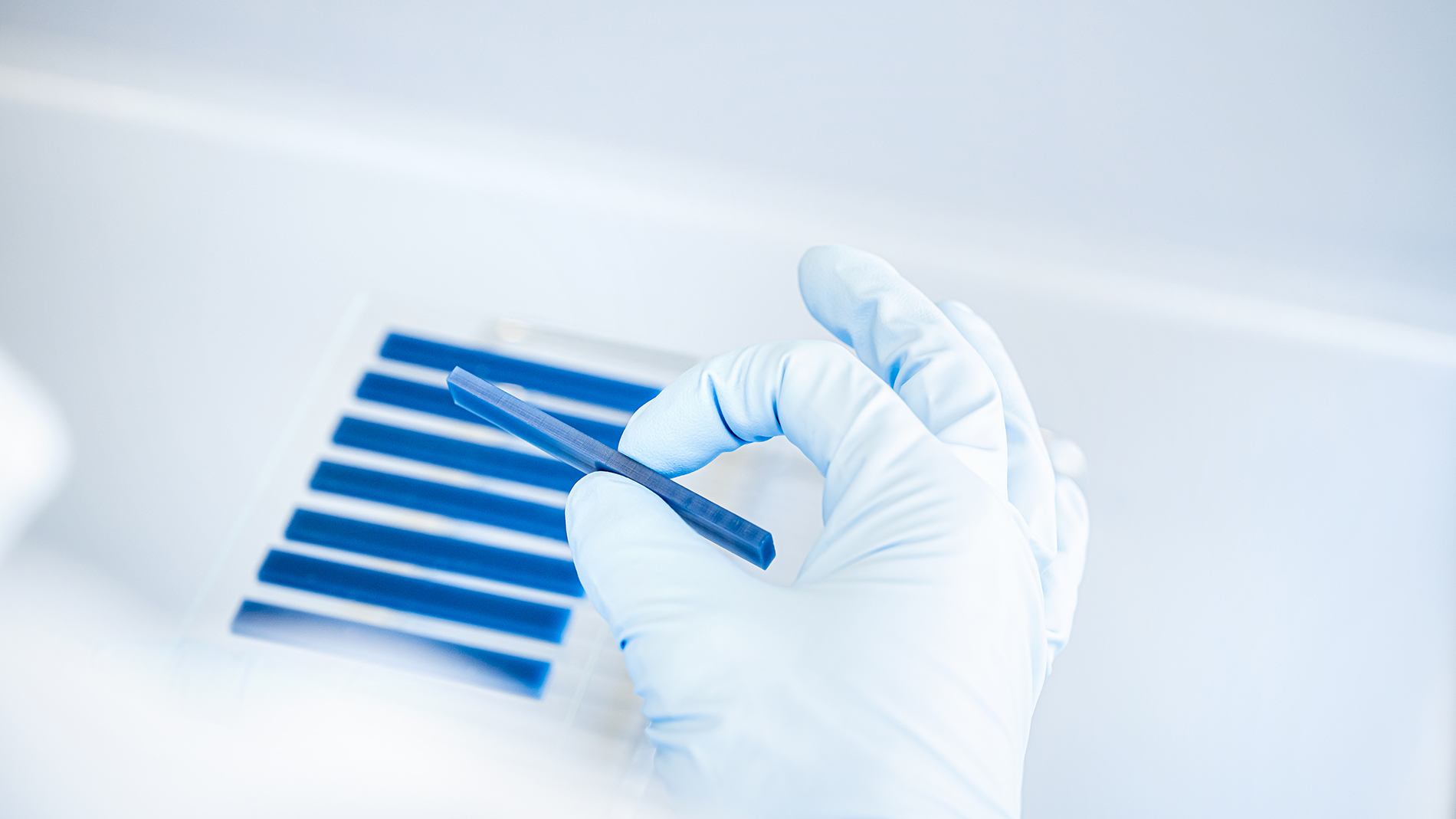

Improving the production of hearing aid geometries

The specialty chemicals company Altana will be showcasing new resin-based Cubic Ink printing materials at Formnext 2023. In addition to improved materials for functional prototyping in the Flexible, Rigid, Tough, Clear and Dental classes, it plans to launch a new Mold product series with two initial materials, Mold 100 VP and Mold 200 VP. These products can be used to produce molds for audiology applications. According to Altana, molds made from these materials facilitate the release of silicone bodies after curing, which makes the production of hearing aid geometries (for example) much easier.

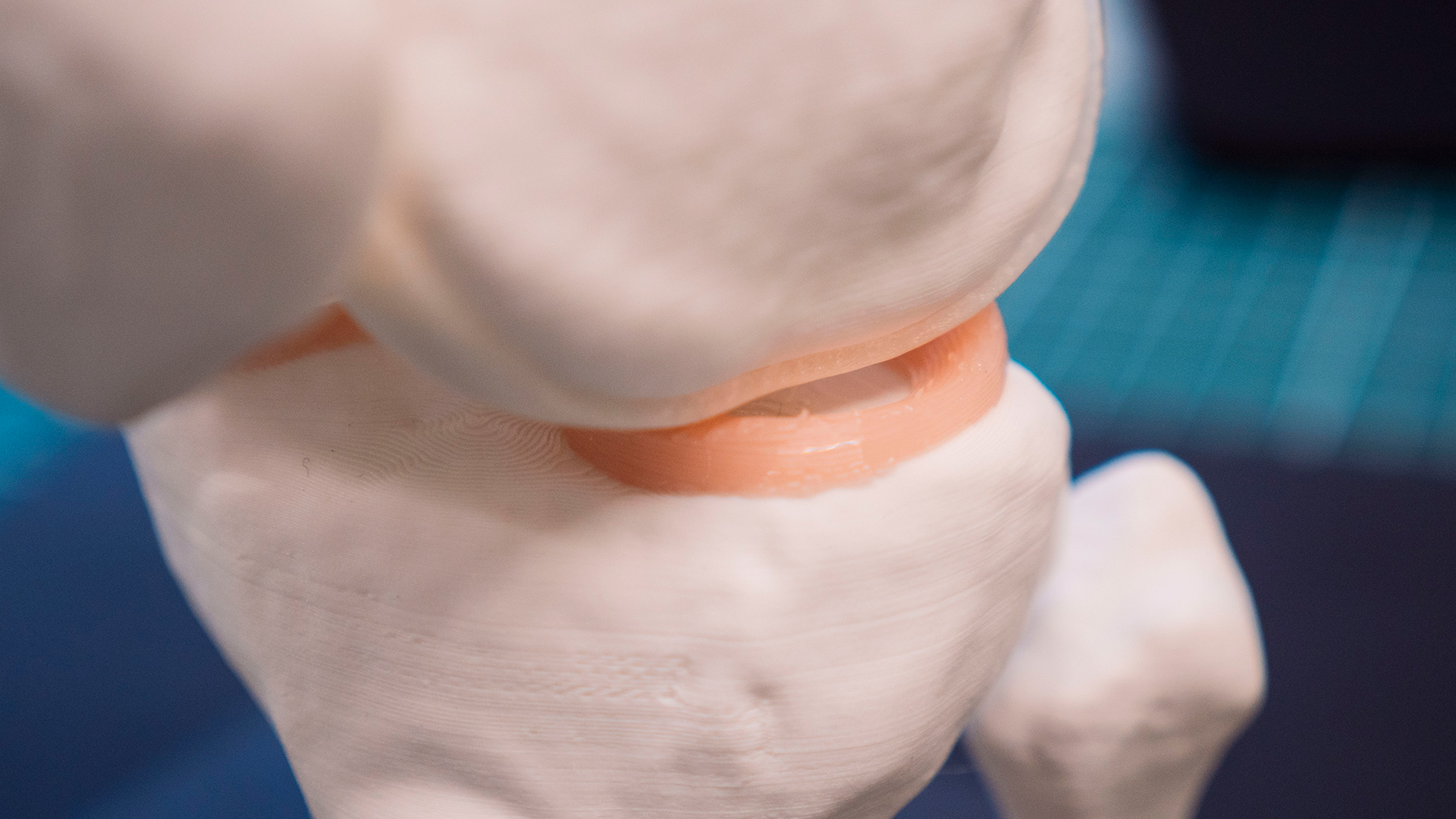

Silicone parts for industry and medicine

Elkem Silicones will be showcasing silicone parts printed using its AMSil and AMSil Silibione technologies. This product series enables the production of functional parts from truly 100-percent silicone elastomers using LDM technology. With the AMSil 20000 series, Elkem is targeting industrial applications in areas such as aerospace, automotive, electronics, and appliances. The AMSil Silbione 24000 series, meanwhile, focuses on medical applications. Elkem Silicones aims to improve the quality of life of aging populations.

Higher printing speeds

Xioneer is poised to launch the new soluble support material VXL 150 for high-speed printing and a large, modular station for support removal, cleaning, and drying for the FFF 3D printer market. By rolling out its soluble support materials for high-speed printing, Xioneer aims to overcome previous limitations in this area. Depending on the material combination and printer settings at hand, an interface can be printed at speeds over 300mm/s, which is particularly crucial in light of the growing demand for additive series production of final components as a means of significantly reducing production times.

Tailored nanoscale alloying

The materials science company Forge Nano has announced a new range of innovative additive manufacturing techniques using its proprietary Atomic Layer Deposition (ALD) method. This new manufacturing process offers improved flowability of suspensions and transports; increased powder bed volume density; and reduced voids, occlusions, keyholes, porosity, and contaminants in sintering. ALD manufacturing techniques also offer improved optical absorptivity and oxide dispersion strengthening, a better hygroscopic barrier, tailored nanoscale alloying, and reduced hazardous reactivity.

FURTHER INFORMATION:

Numerous other highlights and premieres for Formnext 2023 can be found in the trade show issue of FonMag.

Tags

- Materials

- Formnext News