17 May 2024

As one of the world’s largest fast-moving consumer goods (FMCG) companies, Unilever is constantly developing new products for everyday use – from personal care to home care, nutrition, and more. FMCG is an industry in which constant consumer demand drives fierce competition, which is why brands have to continuously innovate and adapt their product strategies. One important area of innovation is packaging: the design of a bottle can sometimes affect customer perception as much as what’s inside.

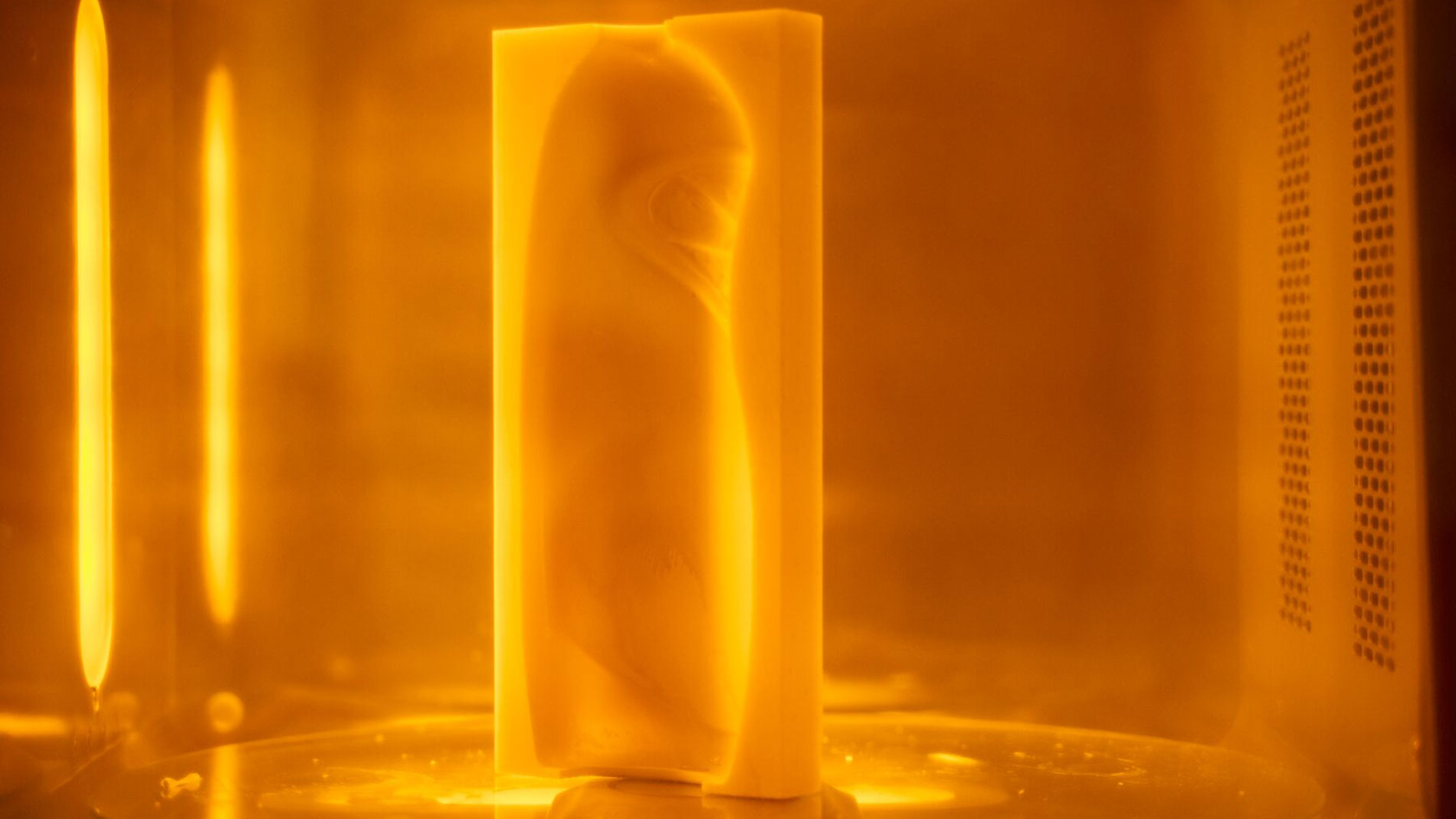

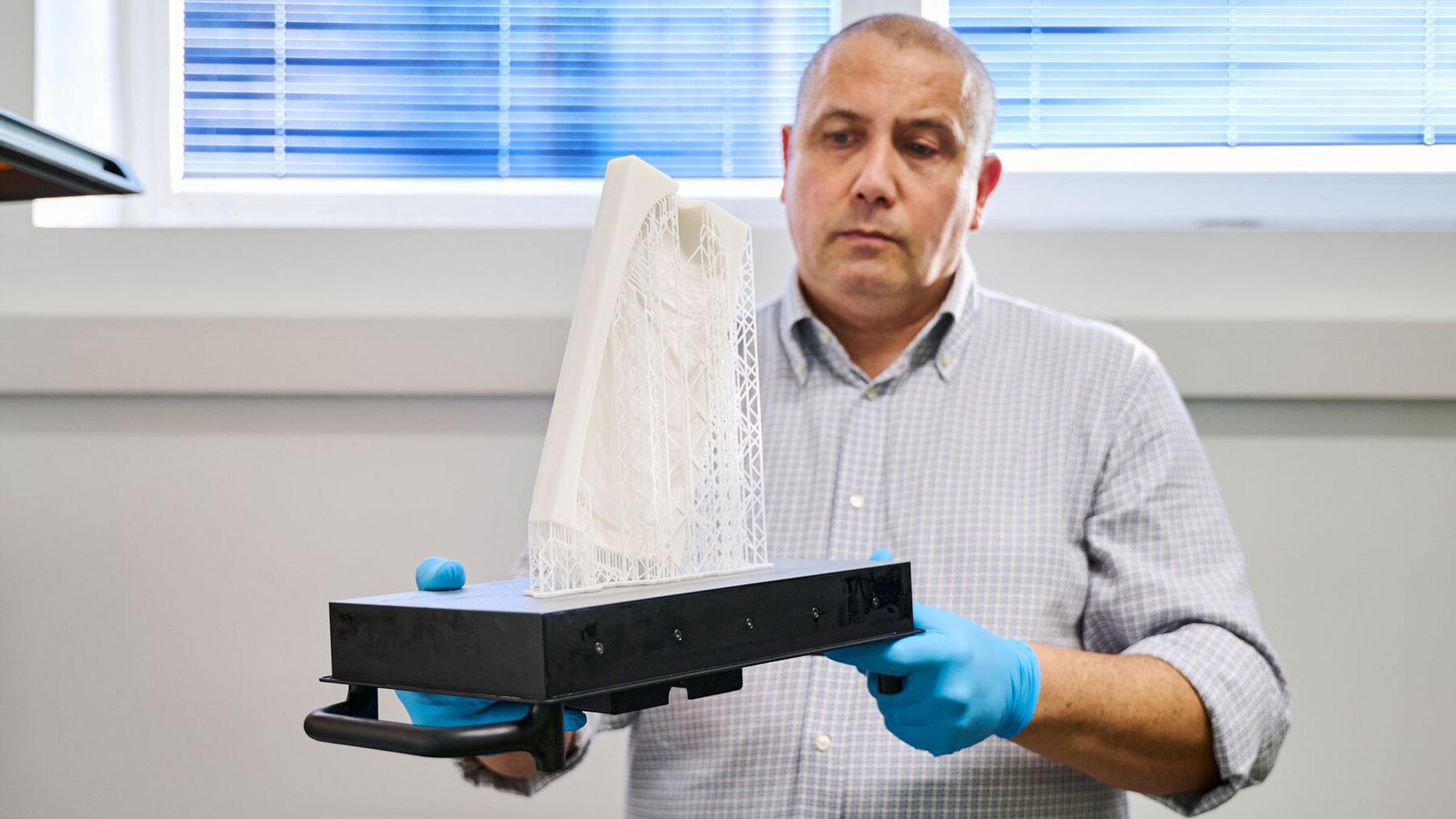

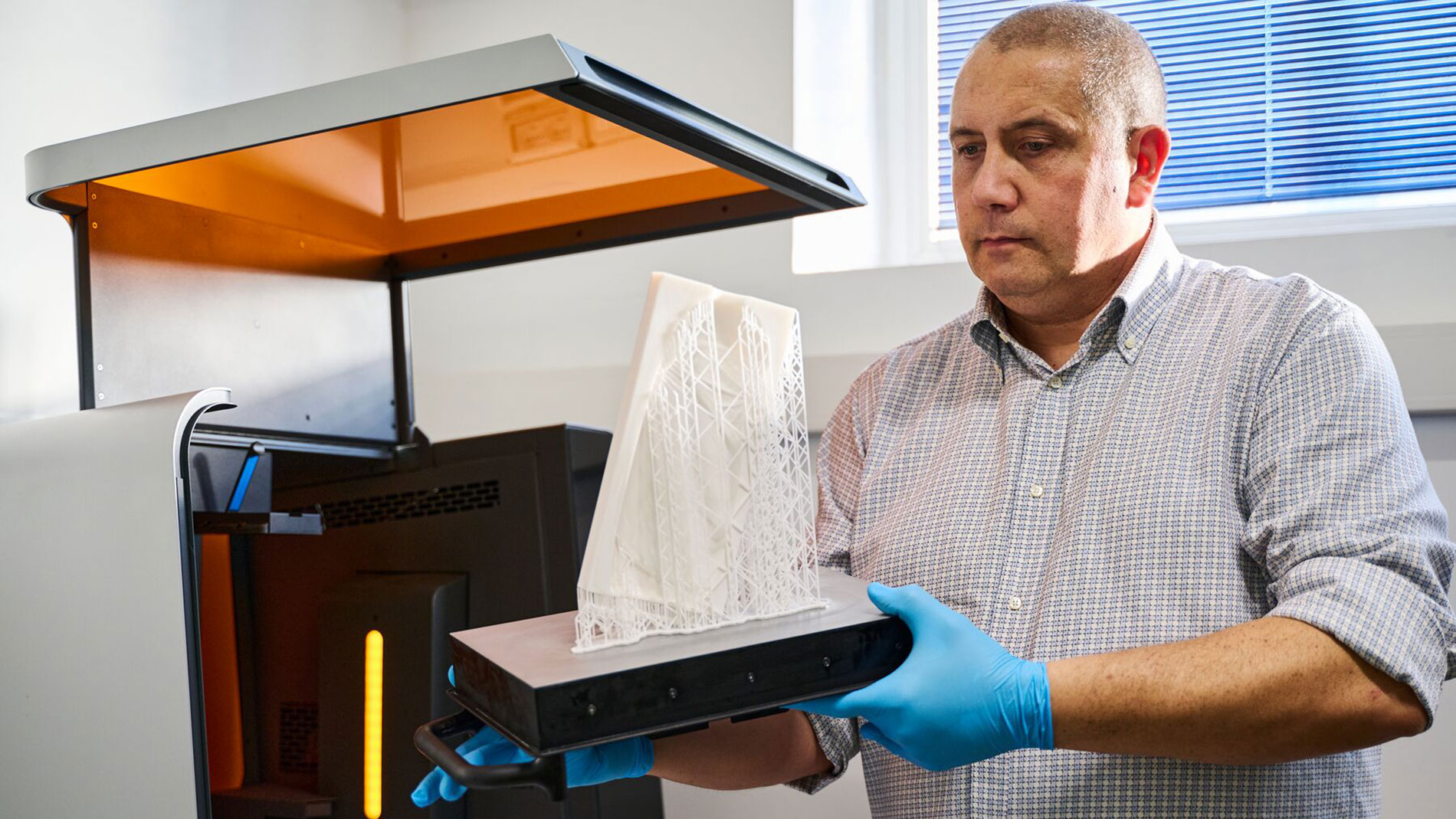

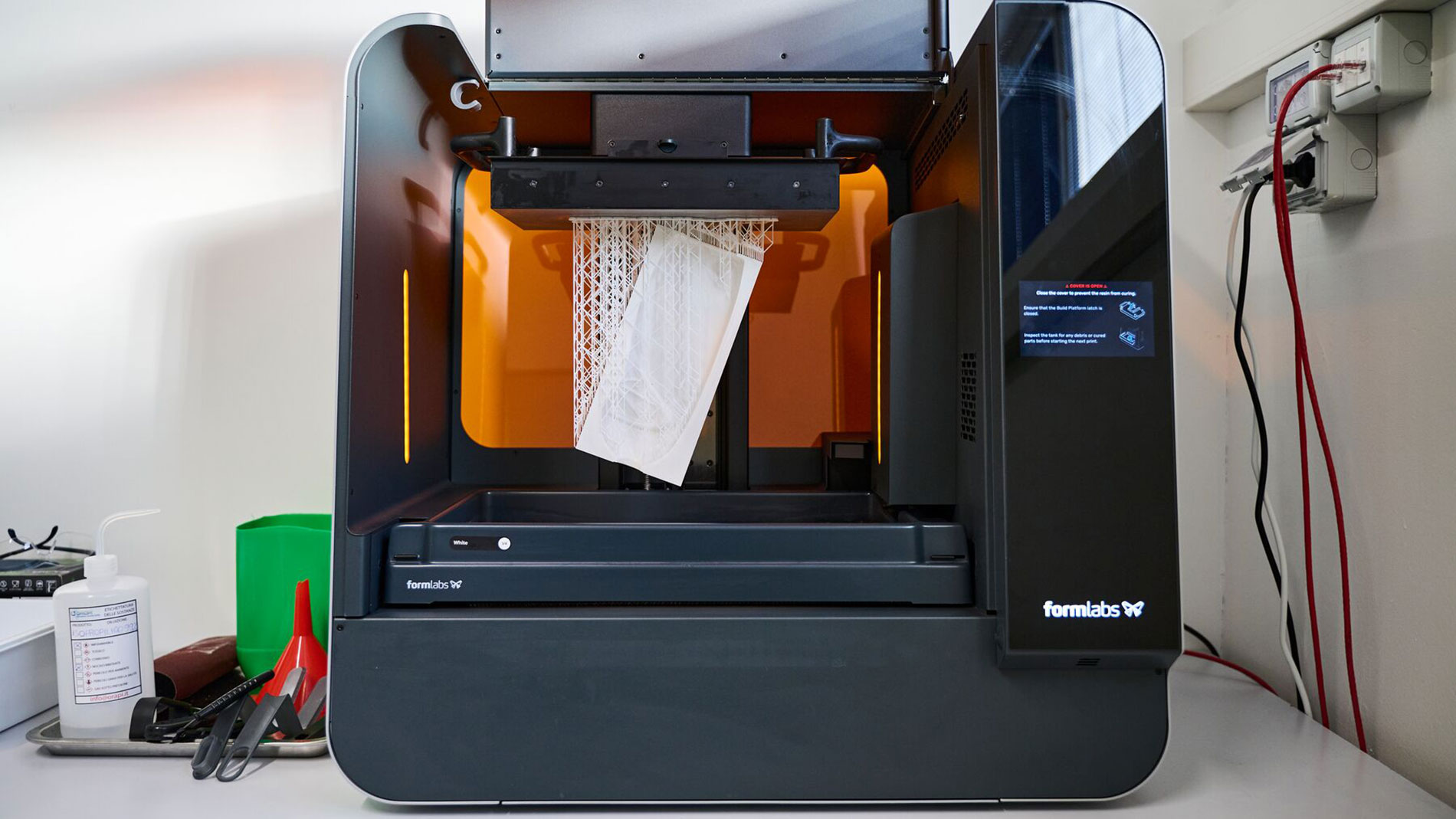

Even with "simple" plastic bottles, however, it used to take months for a design to make it from the computer screen to an actual bottle being filled on the production line. With the help of Additive Manufacturing, this process has now been significantly shortened. In cooperation with Formlabs, molds were 3D-printed to produce sample parts for consumer tests. "You can have a real bottle before you do the real mold, so you can identify immediately if you’re on the right path in your development or need to change something to avoid mistakes that can cost more," explains Stefano Cademartiri, owner of CAD and prototyping at Unilever.

Mass production using the blow molding process

Plastic products such as food and beverage containers, cosmetic packaging, and medical packaging are most commonly produced with blow molding, which refers to a set of long-established methods for the rapid mass production of high-quality, thin-walled parts. Blow molding has very short cycle times – typically between one and two minutes – and is extremely cost-effective for high-volume production. It is usually employed to produce millions of identical parts at low unit costs.

One of Unilever’s major partners in developing and producing packaging for the home and personal care market is Serioplast Global Services. Founded in Seriate (Bergamo, Italy) in 1974, Serioplast is a global producer of rigid plastic packaging for the FMCG industry that produces four billion PET, HDPE, and PP bottles per year.

Not robust enough or too expensive

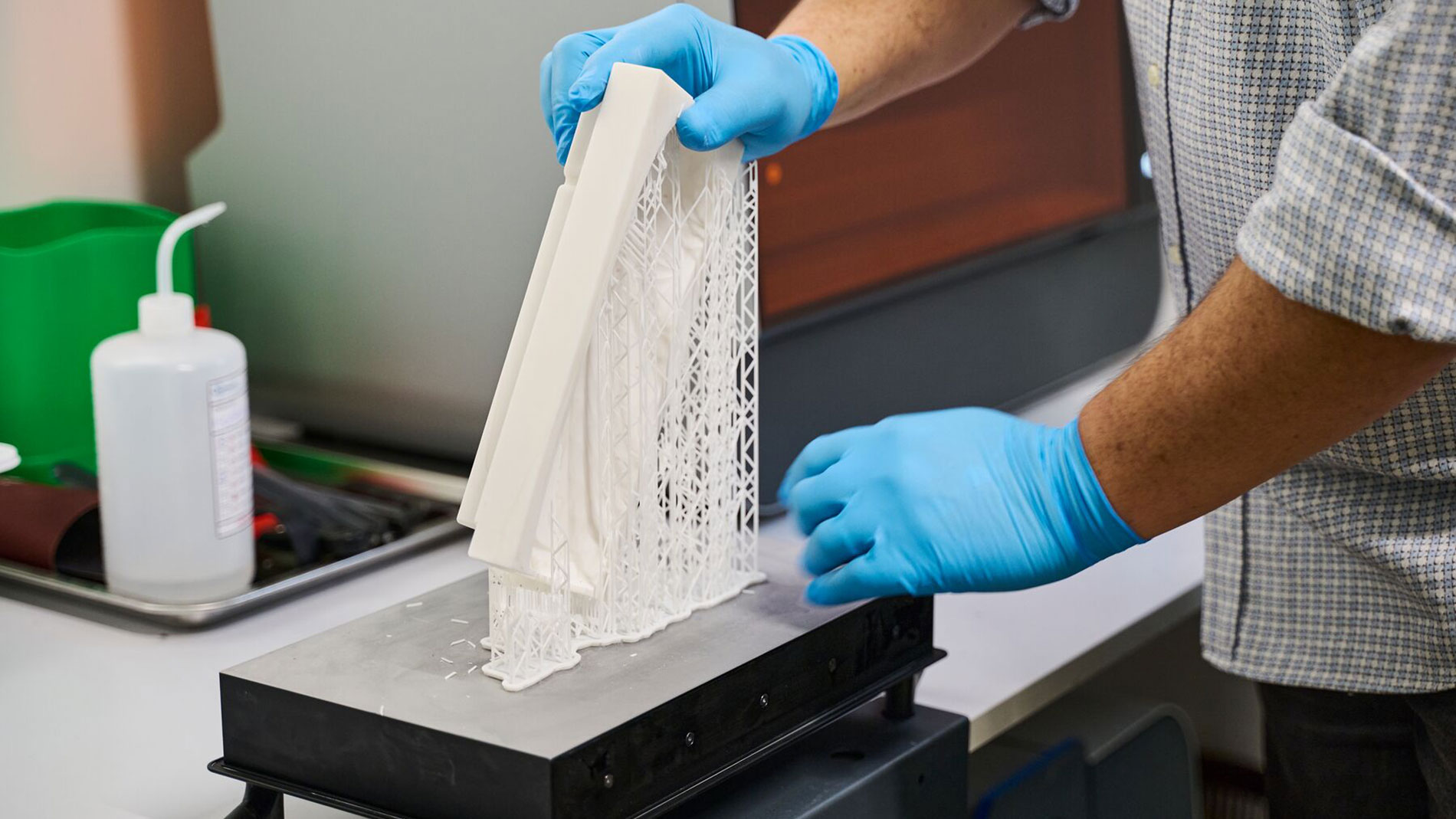

Typically, Serioplast would either 3D-print mockups for prototypes directly or produce them through blow molding, but most 3D-printed mockups lacked the right feel or transparency and were not reliable enough to be sent to consumers. Blow-molding prototypes, on the other hand, is expensive and time-consuming, as a metal tool is required. Such a mold is machined conventionally, which usually takes four to eight weeks and costs from €2,000 to over €100,000 depending on the complexity of the part.

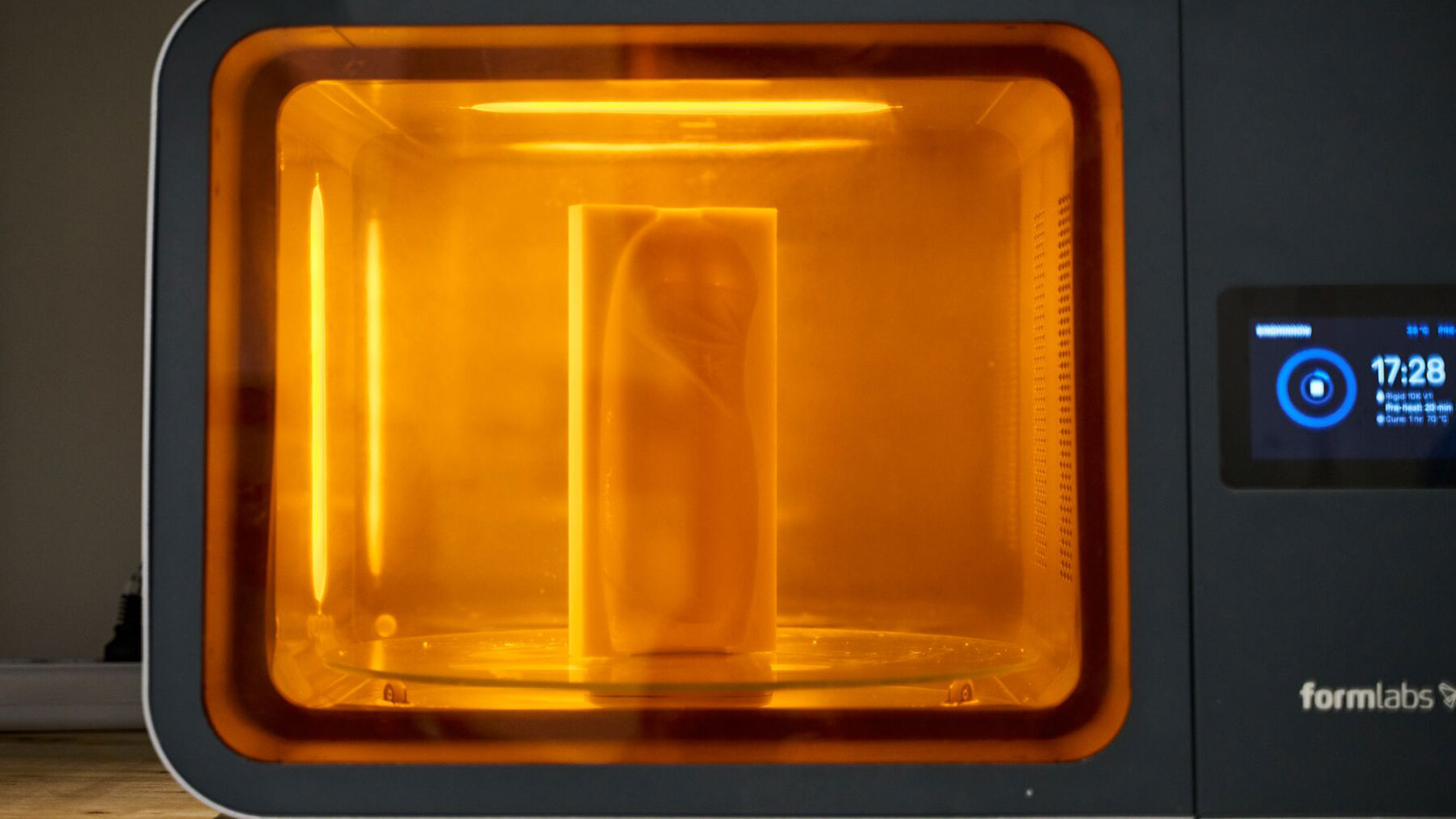

The right material is crucial for 3D printing a blow mold because it has to withstand the internal pressure and temperature of the blow molding process while providing good dimensional accuracy and stability. Rigid 10K Resin is the material recommended by Formlabs for stretch blow molding. This is a highly glass-filled, industrial-grade material with a heat deflection temperature (HDT) of 218 degrees Celsius at 0.45 megapascals and a tensile modulus of 10,000 megapascals.

After 3D printing, the mold is reworked with a polishing machine or by means of manual grinding in order to maintain its exact dimensions. With SLA 3D printing, molds can be produced in just two days, which "saves us up to 70 percent in time and 90 percent in costs compared to a standard mold," explains Flavio Migliarelli, R&D design manager at Serioplast. "In the past, clients had to wait up to 12 weeks just for a single design. Now we can make five!"

FURTHER INFORMATION:

Tags

- Services

- Packaging industry

- Tool and die making