16 May 2024

The BMW Group is testing the wire arc additive manufacturing (WAAM) process at its Additive Manufacturing Campus in Oberschleissheim to produce metallic vehicle components and tools. The campus brings together production, research, and training in this area under one roof. With more than 30 years’ experience, the company is a pioneer in the area of additive manufacturing.

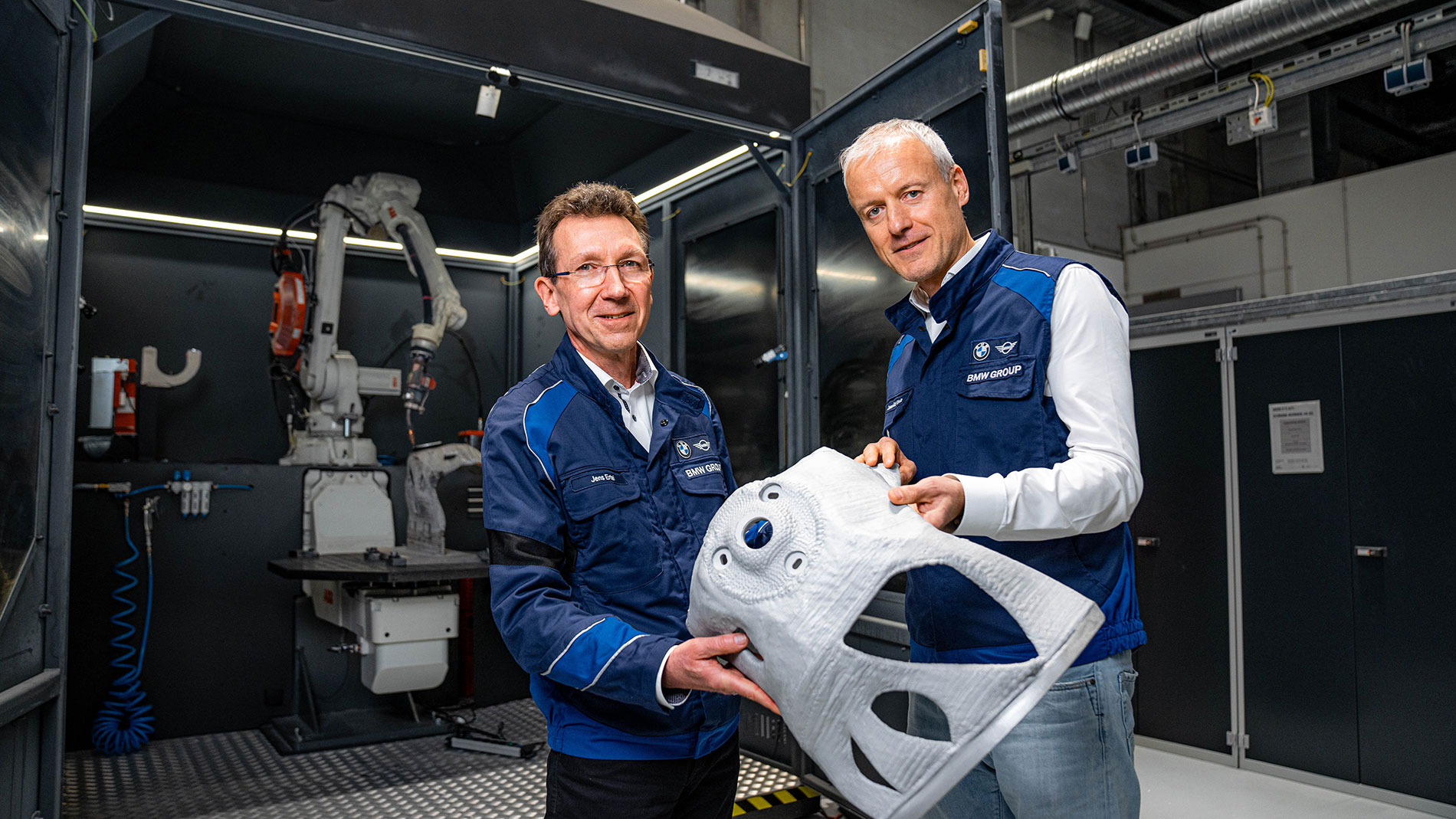

The BMW Group has been working with the WAAM process since 2015, and a WAAM cell has been used there for the production of test components since 2021. One such component is a suspension strut support that is being compared to a corresponding series part made of die-cast aluminum in extensive test runs. "Even at this early stage of technology validation, it’s clear that the WAAM process can lead to lower emissions in the production process. Components can be produced more efficiently thanks to their lower weight, the favorable material usage ratio, and the possibility of using green electricity," reports Jens Ertel, head of BMW Additive Manufacturing. The next development step on the way to series production is testing components in vehicles, which will begin in the foreseeable future.

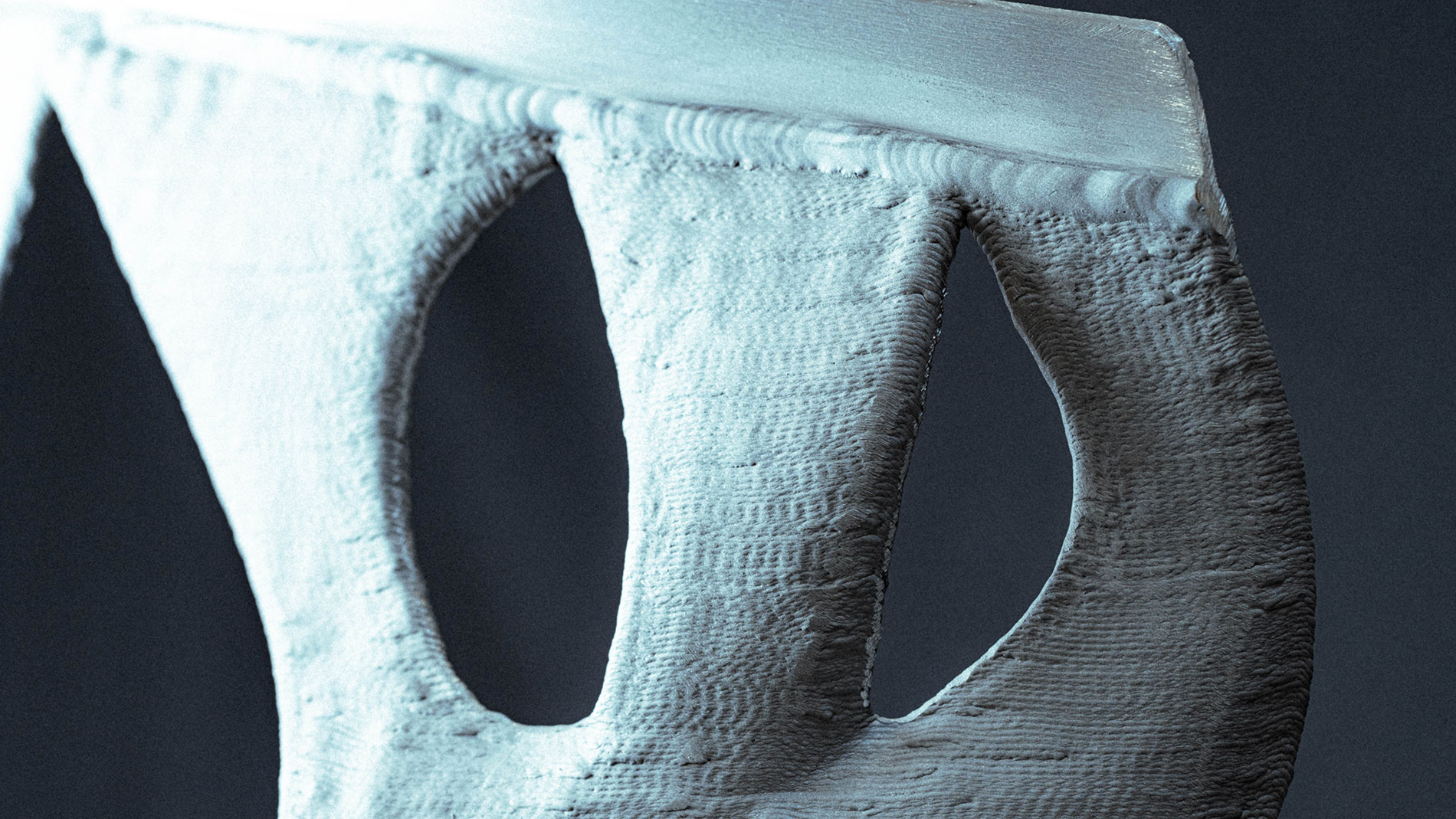

In contrast to laser beam melting, which is already used in prototype and small-series production at the BMW Group, WAAM is particularly suitable for larger parts. The typical wall thicknesses are well suited to body, drive, and chassis components. However, tools and devices can also be produced using this process.

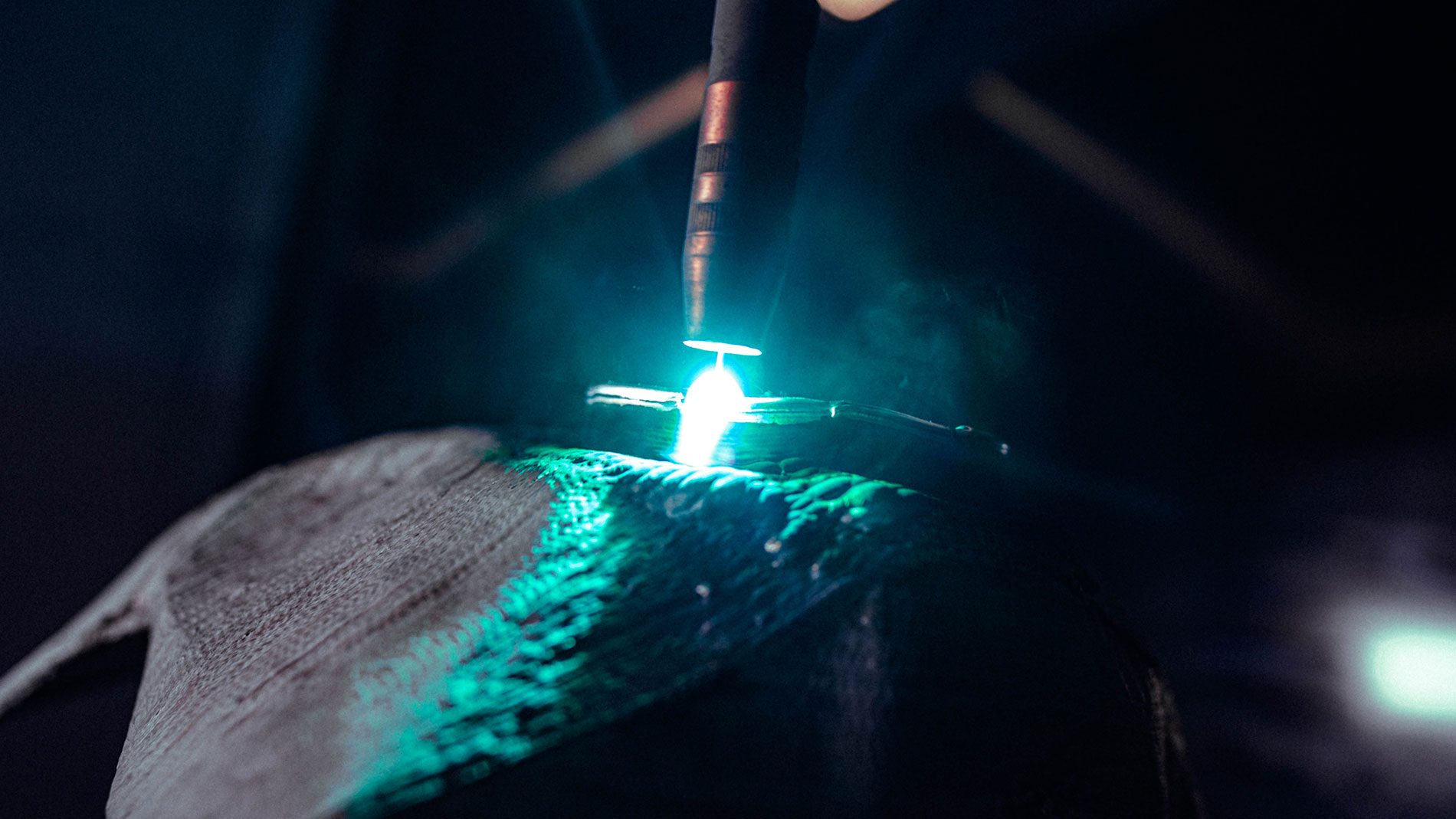

The wider welding seams in the WAAM process mean that the surfaces of the components are not smooth, but slightly rippled and must be finished in critical areas. However, BMW Group engineers were able to demonstrate that WAAM components can be used for high loads, including cyclical loads, even without post-treatment of the surface. Optimised process parameters are crucial for ensuring durability directly from production, so the combination of welding process and robotic path planning must be coordinated optimally.

“It’s impressive to see how WAAM technology has developed from research to become a flexible tool for not only test components but also series production components. The use of generative design methods enables us to make full use of design freedom and thus the potential of the technology. That was unthinkable just a few years ago,” said Karol Virsik, Head of BMW Group Vehicle Research.

Initially, the BMW Group is planning to use WAAM to produce components centrally in Oberschleissheim, but it may be rolled out to other locations and suppliers in the future. Further, it would even be conceivable to produce individual components directly on the assembly line using this process and to manufacture different parts without new tools, simply by changing the software. Sustainability can also be further improved by increasing the use of recycled metals.

FURTHER INFORMATION:

Tags

- Automotive

- Additive Manufacturing

- Research and development