Text: Thomas Masuch, 17 May 2024

In just under two years, 3D printing has turned into a real success story at Erco

Erco’s first attempt at 3D printing came to a rather sobering end. “Almost 10 years ago, we’d already taken a look at whether we might be able to use AM to produce components for our lights,” recalls Stephan Jungkurth, head of tool engineering at the company. Erco, which specializes in high-quality architectural lighting, does seem like a prime candidate for 3D printing: There’s a great deal of variance in its products, and it produces different quantities depending on the order at hand. “In the end, however, it didn’t make economic sense. For the products we make for the premium segment, we need really high-quality surfaces – the kind you can only get with printed parts if you spend a lot of time on post-processing,” Jungkurth reveals.

After its initial foray, Erco nonetheless kept a constant eye on this innovative manufacturing technology. Its next attempt to establish AM at the company started in 2021 – not in the production of components for finished products, but in connection with equipment and operating facilities that fall within the 37-year-old Jungkurth’s purview.

Erco took the first steps along with a service provider from its region that supplied it with some initial sample parts. Meanwhile, the specialists in Erco’s design engineering department were able to learn more and more from the provider about dealing with supporting structures, overhangs, and infills. “We’re still learning, but that was the period when the learning curve was the steepest,” Jungkurth says before adding in summary: “It was definitely the right decision to work with a service provider first. I’d do it again any time we were introducing a new technology.”

Cost recouped in just a year

Erco’s 3D-printed parts made a compelling case more or less straightaway. As the demand for them grew, purchasing a printer for in-house use was the obvious next move. Jungkurth drew up a “very conservative” amortization plan that projected Erco would recoup its investment in three to four years at the latest.

A Markforged X3 then made its debut in Erco’s tool engineering department in Lüdenscheid (western Germany) in May 2022. “Since then, we’ve churned out so many parts that the printer paid for itself in one year,” Jungkurth reports. He’s talking about around 1,500 components, and the X3’s display bears that out, reporting an impressive 11,400 hours of use. The unit typically produces layers and infills 18 hours a day, which makes it one of the most utilized machines at the company.

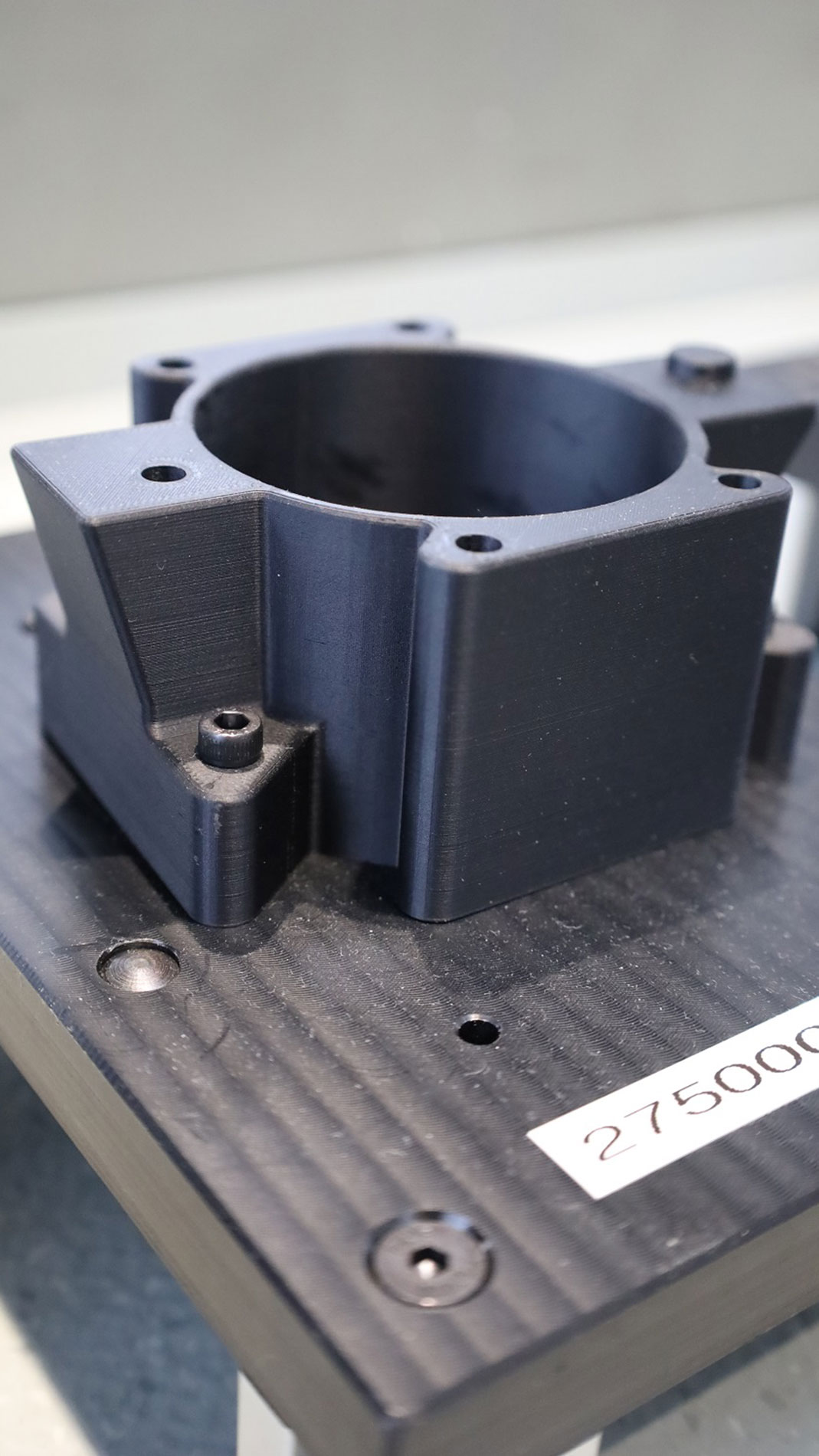

ESD material is key

In its production operations, Erco has to pay continuous attention to the issue of static discharge in order to protect the sensitive electronics in its lights. Its employees even wear shoes and clothing interwoven with carbon fibers that help them conduct electricity. Erco’s 3D-printed parts also need to be conductive, of course. In his search for suitable synthetic materials, Jungkurth says Markforged was the only company offering something with the right ESD (electronic static discharge) properties.

Once Erco’s design engineers send their creations to its tool engineering department, they find their way to the 3D printer. “Thanks to the experience we gathered with our service provider, we didn’t have much trouble getting started,” Jungkurth says. Printed components are usually taken out of the printer during the morning shift and then assembled. “On the whole, we’ve not only saved a lot of money, but significantly shorted our entire process chain, as well,” Jungkurth explains, gesturing toward an area of the production hall in which injection-molding machines are being stored on a row of wooden pallets. “That used to be where we kept the semi-finished products we milled into parts for fixtures. These days, we basically don’t need them anymore.”

Expertise in lighting

Echoing a common theme, Erco’s tool engineering department features tall windows that let plenty of light in. The adjacent foyer includes a type of showroom in which Erco presents various types of lighting that are designed to provide just the right illumination, whether for works of art at museums, workspaces at offices, or the facades of buildings. For shops and the retail sector in general, the company also offers technical accessories such as filters that modify the light spectrum and lend products like fish or meat a fresher appearance.

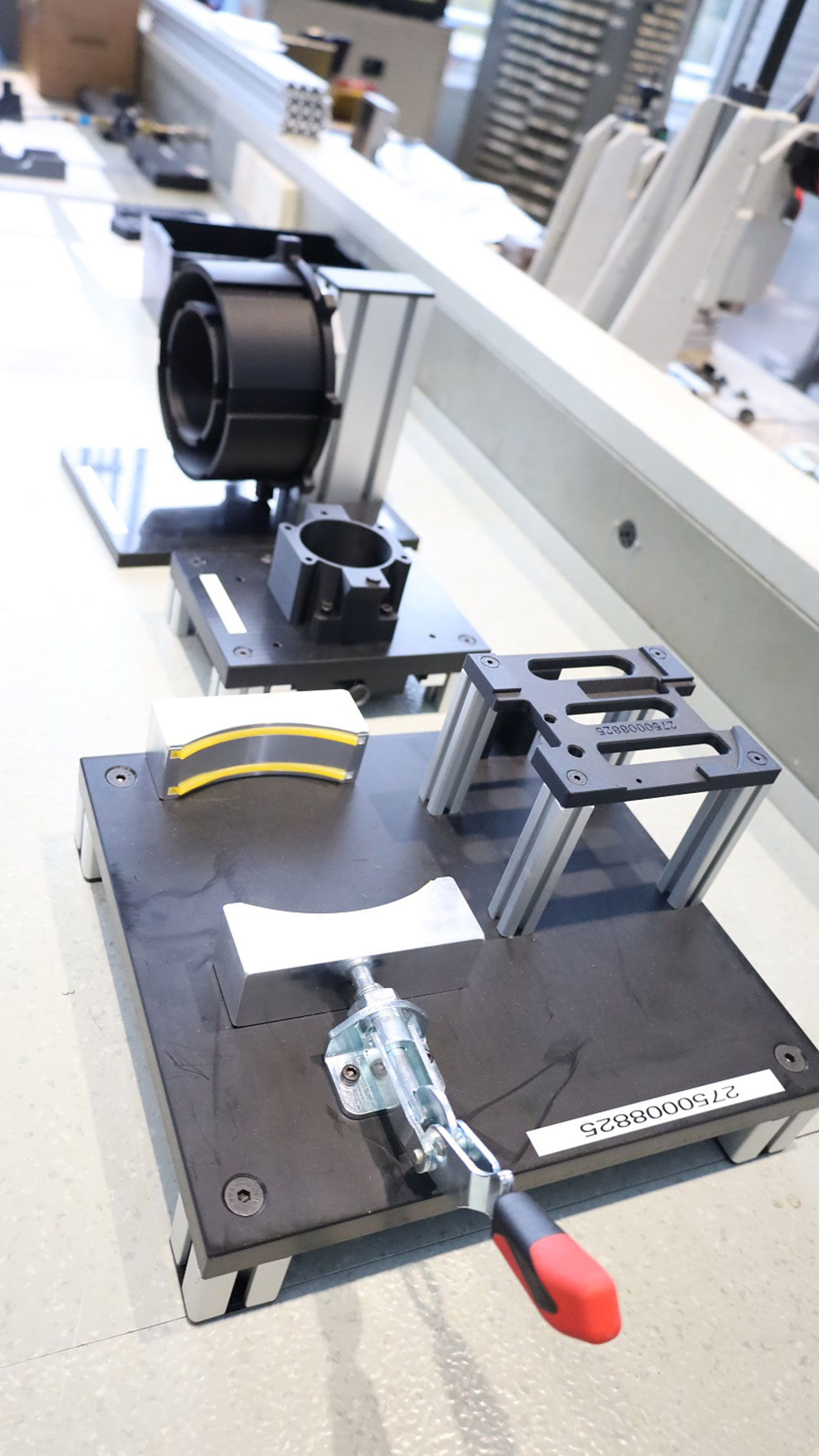

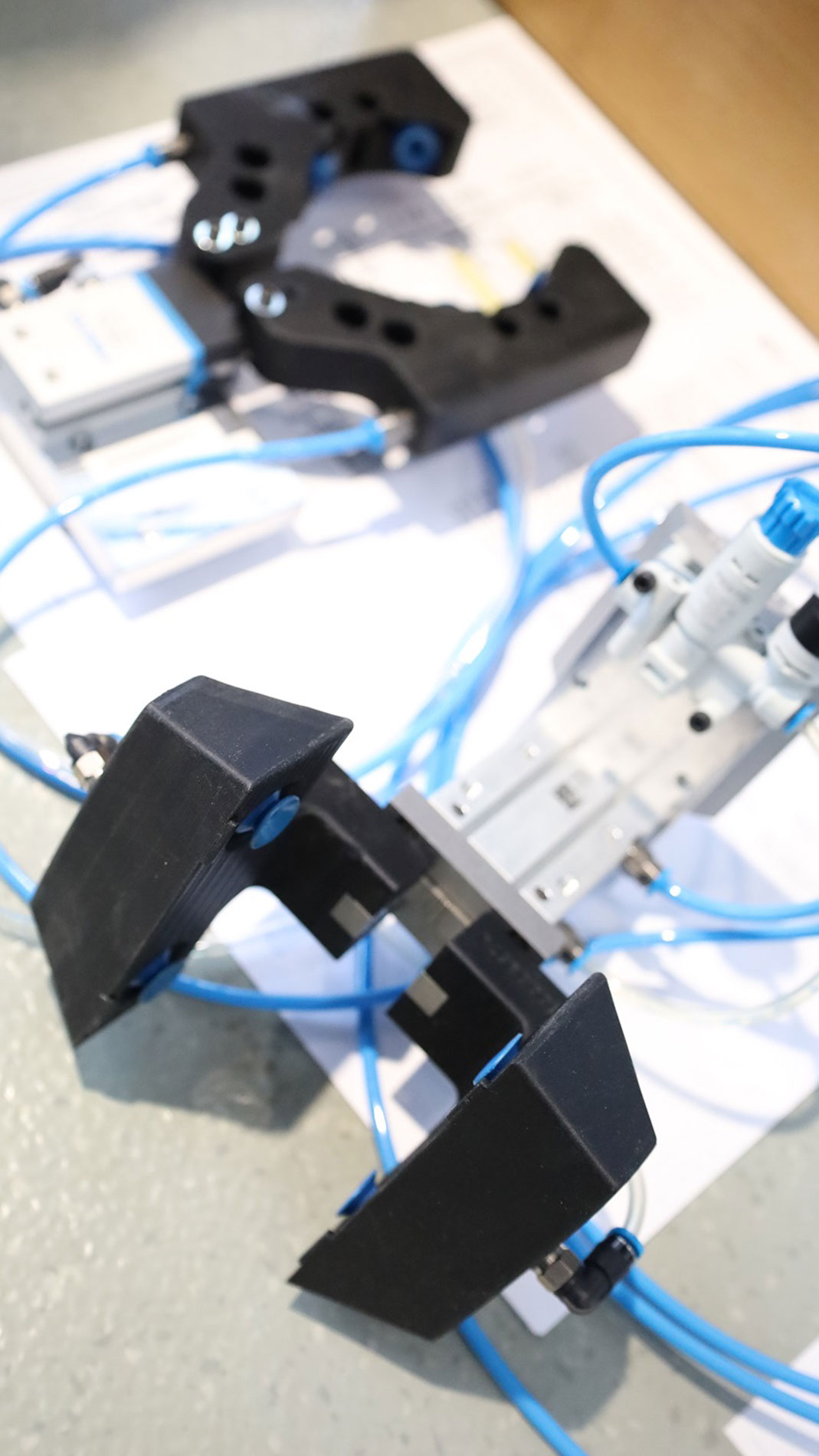

Meanwhile, every new product requires new fixtures. The same need also arises when production processes are optimized or certain lights prove so popular that Erco has to set up a second production line. Its 3D-printed components go into not just a wide variety of test and mounting fixtures, but various gripper elements and handling systems, as well.

Some 250 fixtures

Last year, Jungkurth and his team produced a total of around 250 such fixtures. “What’s helped us a lot is the way 3D printing has really streamlined the process and enabled us to work more efficiently,” he points out.

Having had such a positive experience with the technology, Jungkurth is now keen to leverage it in other areas at the company. “We’re looking for new opportunities,” he affirms, citing hand samples for product development and the masking of holes and screw threads for painting purposes as examples. He also sees potential in 3D-printed inserts for injection molds. These make several dozen shots possible in some cases, which Jungkurth says covers Erco’s requirements for an entire year for certain products. This would enable the company to offer efficient solutions for even more customer-specific needs – including in situations where traditional toolmaking wouldn’t be cost-effective. Someday, Erco might even print parts for its actual lights. Jungkurth is convinced that 3D printing technology “has the potential to advance to that point in the future”.

About Erco

Erco is an international company that specializes in high-quality digital architectural lighting. Founded in 1934, this family-managed business now operates in 55 countries around the world through independent sales organizations and partners. Erco views light as the fourth dimension of architecture. At its production facility in Lüdenscheid, Germany, it designs and manufactures lights with a focus on technical optical characteristics, electronics, and sustainability. Erco creates its lighting tools in close collaboration with architects and specialists in light and electrical planning.

FURTHER INFORMATION:

Tags

- Electronic engineering and electronics

- Tool and die making