Text: Thomas Masuch, 6 November 2024

Sustainability has been one of the key topics at Formnext for several years now. It is becoming increasingly important, especially when it comes to innovations in the field of plastic materials. This is visible (in the true sense of the word) at the Smart Materials booth, which was printed from sustainable materials using around one ton of oyster waste. Reusable cartridges and filament spools are also among the innovations in this area, as is a system for recycling plastic waste. Formnext exhibitors will be showing even more high-performance polymer materials, as well. These are suitable for purposes like making molds or (thanks to their high-quality finishes) producing functional prototypes. Other innovations feature high heat resistance that expands the range of potential applications.

For one-shot molds and light pipes

At Formnext 2024, Cubic Ink, a product line from Altana New Technologies GmbH, will be presenting a number of material enhancements and new developments. Cubic Ink Mold materials are used to produce one-shot molds for classic injection molding, but can also be used as cast material for applications like vacuum casting processes at low temperatures and pressures. Meanwhile, Cubic Ink High Performance 4-2800 VP ESD resin, which is suitable for electrostatically dissipative objects at moderate temperatures, has now been joined by Cubic Ink High Temperature 303 VP ESD. Thanks to its moderate viscosity, this resin is easy to print on all common DLP, LCD, and SLA machines. Objects made from it exhibit a heat deflection temperature of over 220°C.

Aesthetic matte finish

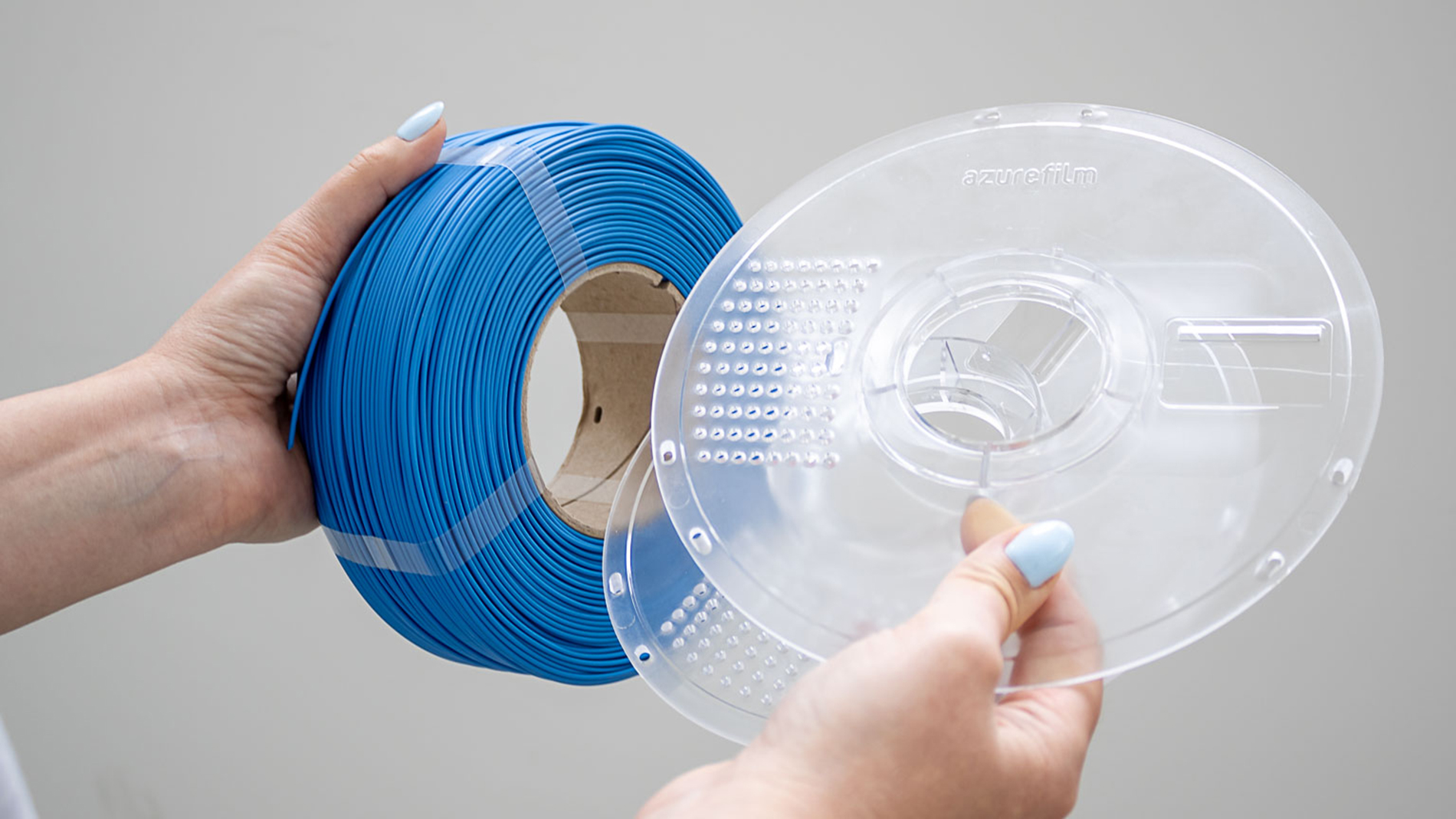

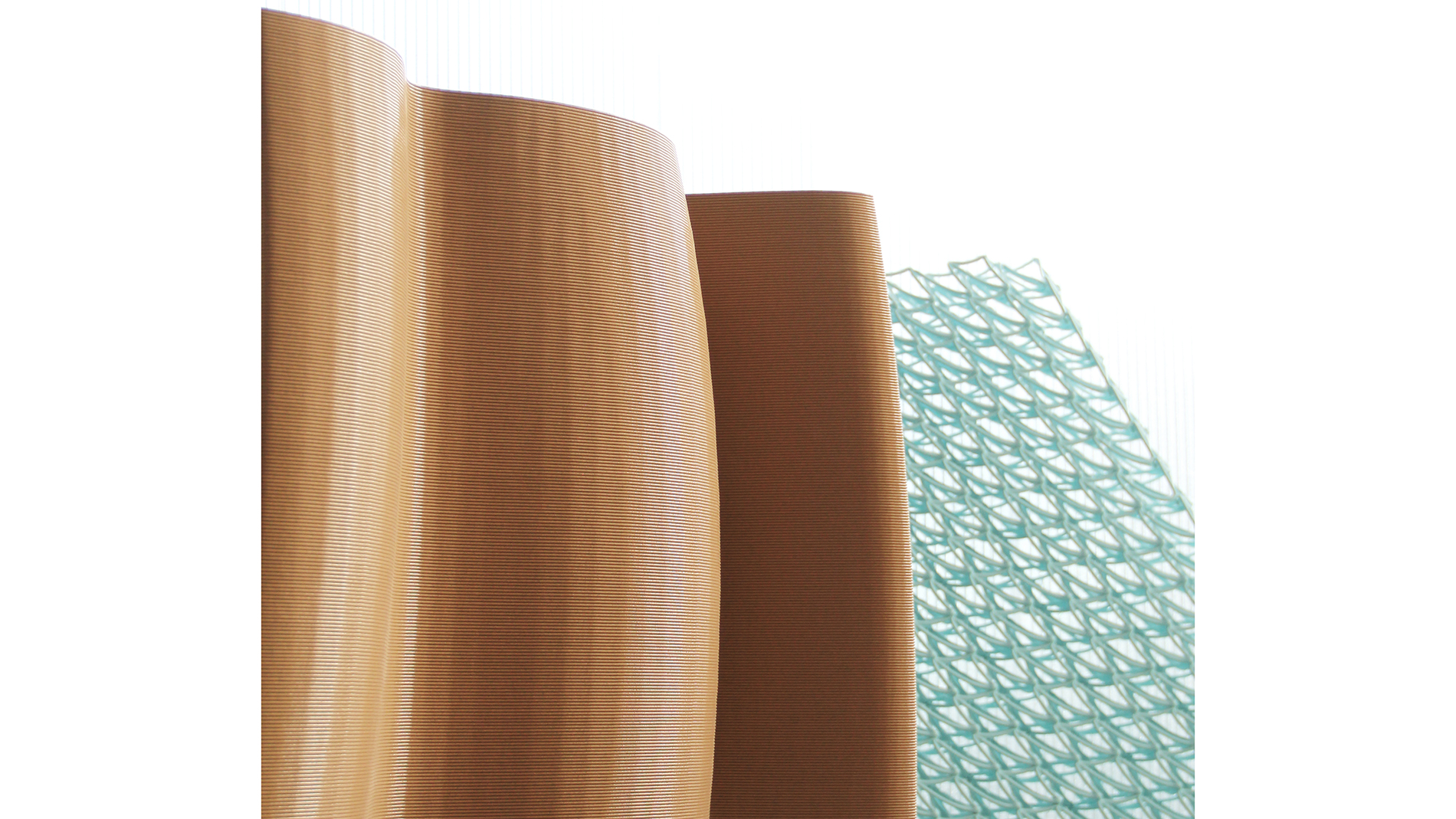

Having launched the Prime, Matte HS, and Refill material collections in 2024, AzureFilm is poised to present them to an international specialist audience at Formnext 2024. One of the special features of the Prime collection is its heat resistance. PLA Matte HS, meanwhile, was developed to offer an aesthetically pleasing matte finish. It is suitable for a wide range of applications, from decorative objects to functional prototypes.

Made from oyster shells, coffee grounds, and olive pits

In collaboration with Nagami Design, Smart Materials 3D has designed the first fully 3D-printed booth made from sustainable materials, which it now plans to present at Formnext 2024. The booth is more than just a product exhibition: every element, from the walls to the tables and chairs, was produced using large-format additive manufacturing (LFAM) technology, which uses robotic arms. The ecologically sustainable materials used for production included organic components such as oyster shells, coffee grounds, pine wood, olive pits, and cork. More than 2,000 kilograms of pellets from the new PelletSmart brand were used for this project. Most of these pellets (around 1,000 kg) were made from oyster waste.

Images: Smart Materials

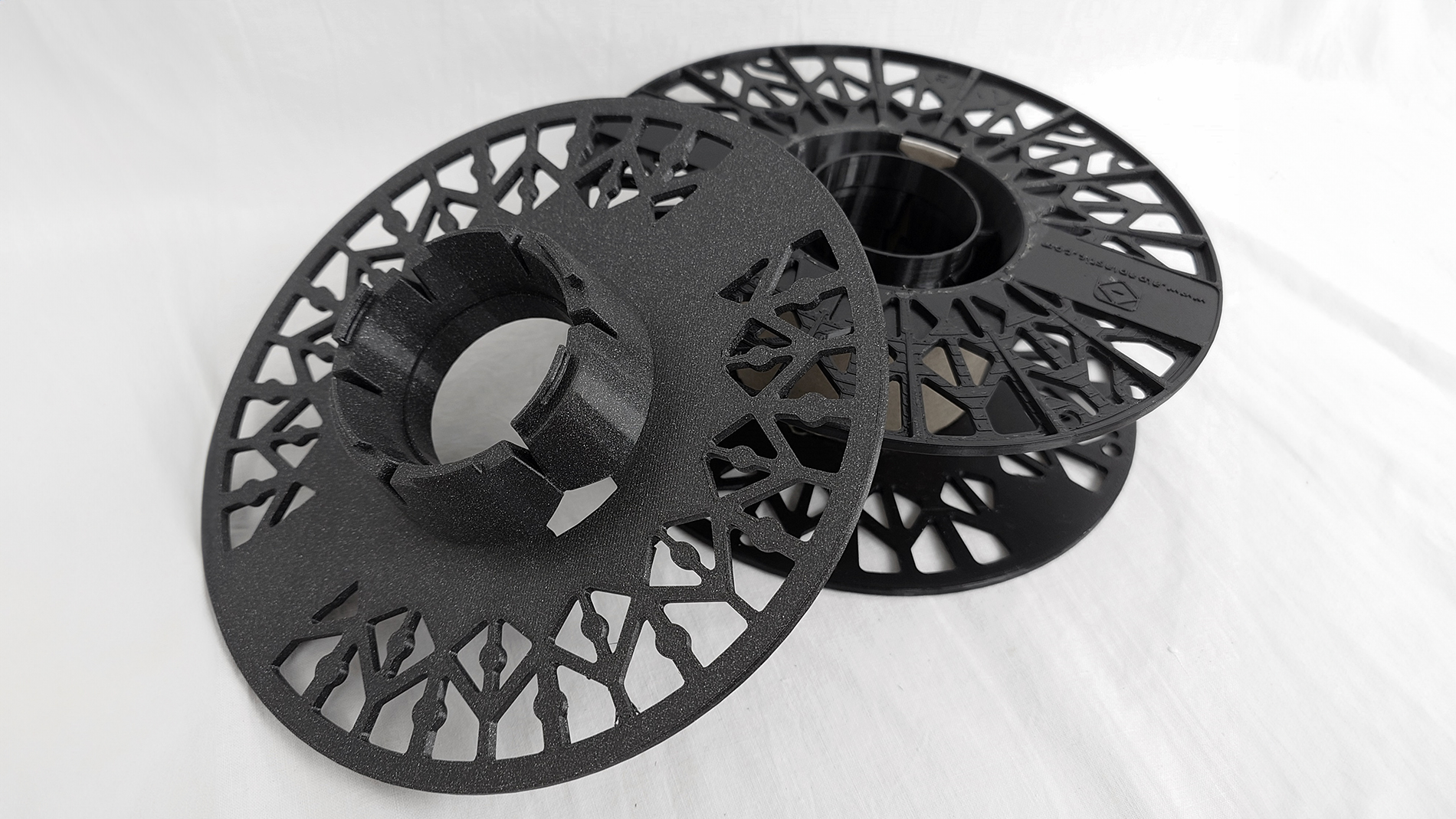

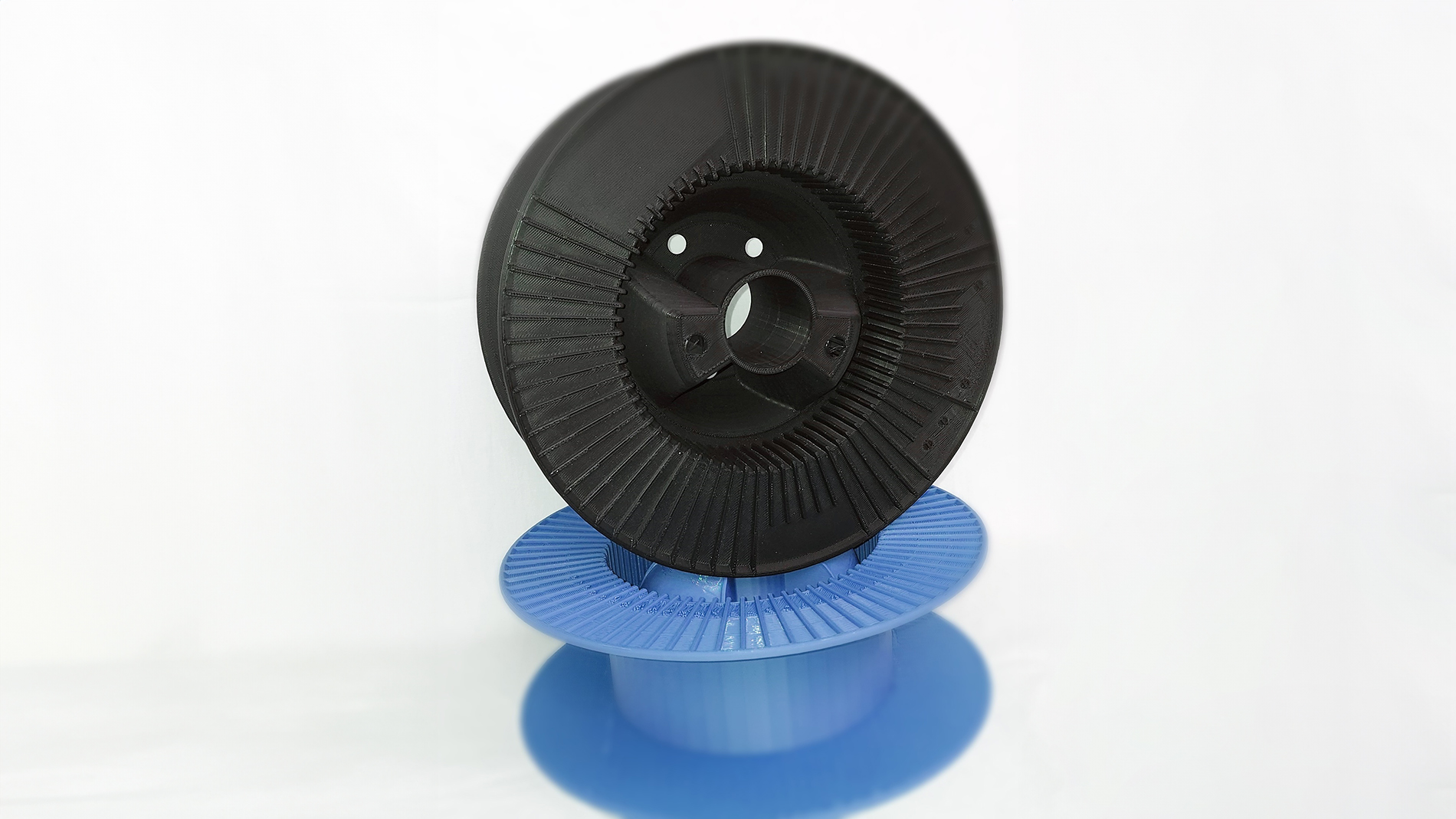

For automatic material loading systems

Focusing on the trends of innovation and sustainability, the Italian company Alpaplastic has two newly developed empty reels in its portfolio. The RS 200 RB spool has been specially developed for users who prefer automatic material loading systems and refillable cartridges. With a capacity of 1 kg for 3D printing filament, it features a compact and stackable design that can be used with or without a cardboard tube. The RS 300/20 spool, meanwhile, offers a capacity of 3 kg.

Reusing spools and reducing plastic waste

The Chinese company Kexcelled will be presenting its Reusable Filament Spool (RFS), which is meant to help reduce plastic waste in the 3D printing industry. “We were shocked to learn that two-thirds of plastic filament spools end up in landfills,” says Wilson Mao, founder and CEO of Kexcelled. According to the company, the RFS seamlessly integrates with most FDM/FFF 3D printers, is designed for long-term use, and is compatible with automated material systems.

High-quality filament from plastic waste

The new Filament Maker 2 from 3devo is set to debut with new sensor integration and improved functionality. The Dutch company also offers the possibility of recycling plastic materials – whether from 3D-printing processes or general plastic waste – into high-quality filament. The new and improved features of the Filament Maker 2 include a fully integrated sensor system which optimizes extrusion control and ensures precision throughout the process.

Images: 3devo

FURTHER INFORMATION:

You will find all the companies mentioned at Formnext 2024:

3devo: Hall 12.1, Booth F139

Altana: Hall 12.1, Booth F12.1-F99

Alpaplastic: Hall 12.1, Booth E48

AzureFilm: Hall 12.1, Booth B19

Kexcelled: Hall 12.1, Booth G19

Smart Materials 3D: Hall 12.1, Booth F39

Tags

- Materials