Text: Thomas Masuch, 24 October 2023

Post-processing is an essential part of additive manufacturing. Corresponding innovations are ensuring improved component quality and increased automation – and many of them are on display at Formnext 2023.

Automation and component quality are indispensable parameters in additive manufacturing. If you want to be successful in this regard, you need innovative solutions in post-processing. After all, the removal of support structures, surface treatment, and other post-processing steps are essential links in the additive process chain that can account for 30 percent or more of production costs. That makes innovations in this area tremendously important for the further development of the entire AM industry.

Smoothing, polishing, finishing

LuxYours will be presenting the new Lux Pro 400, an automated system for smoothing and finishing plastic parts. With a process chamber of 300 x 300 x 400mm and the footprint of a Euro pallet. As a long-standing service provider in smoothing AM components, LuxYours has developed and gradually refined its Multi Purpose Smoothing (MPS) technique. According to LuxYours, the secret of MPS lies in an in-depth understanding of the physical-chemical processes involved and how they interact. Components refined using this technique retain their REACH compliance and are food-contact-compliant according to EU 10/2011.

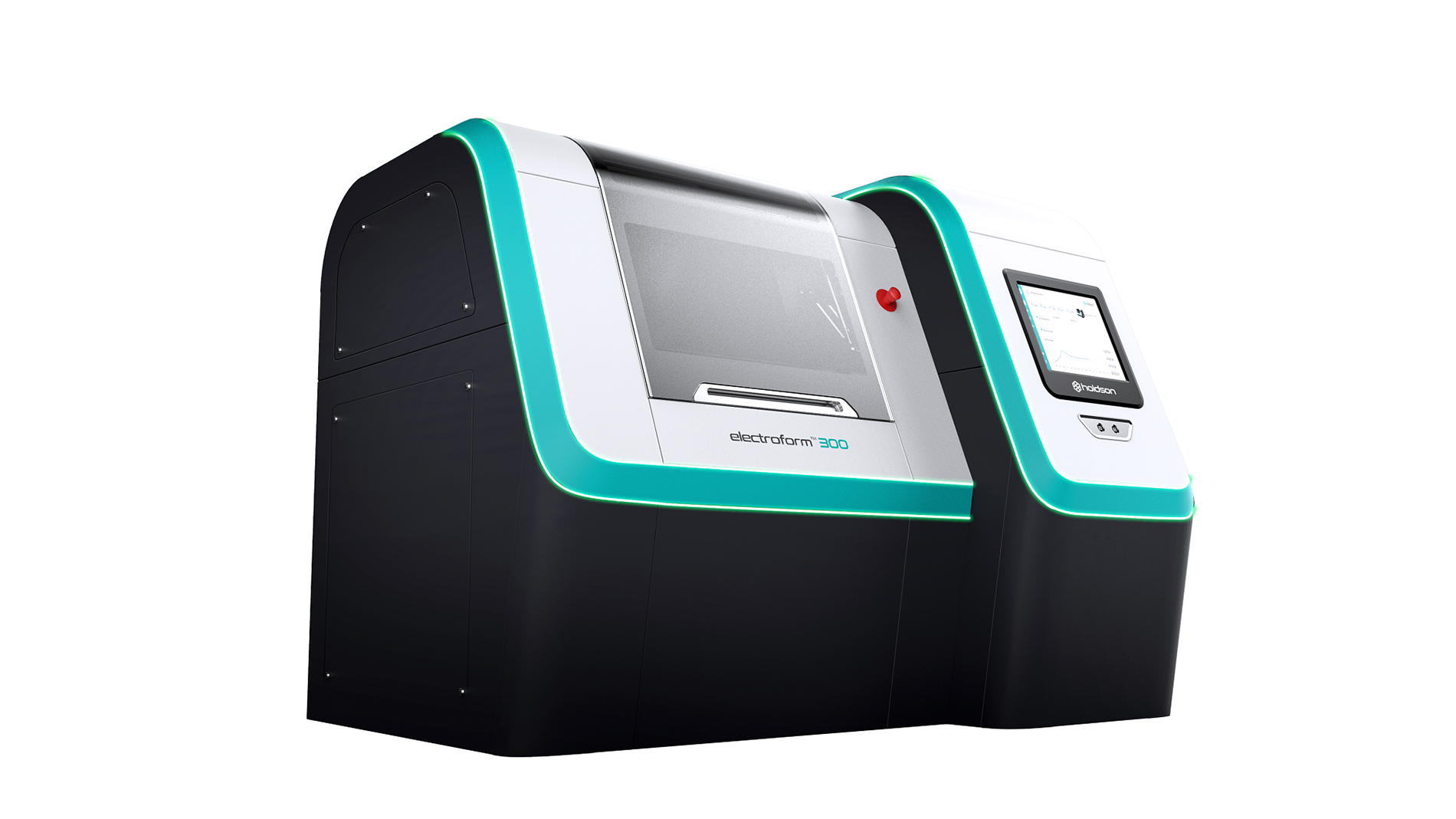

Holdson, a supplier of electrochemical polishing machines, is set to present its Electroform machine at Formnext 2023. With the power of a one-of-a-kind dynamic contour electrode and machine-learning algorithms, the young British company promises that Electroform technology offers “optimal polishing for additively manufactured components”. According to Holdson, the patented machine boasts the ability to reduce surface roughness on metal components by more than 90% in less than five minutes, which makes it possible to control material removal rates.

Images: Luxyours, Holdson, BMF

Spotlight on automation

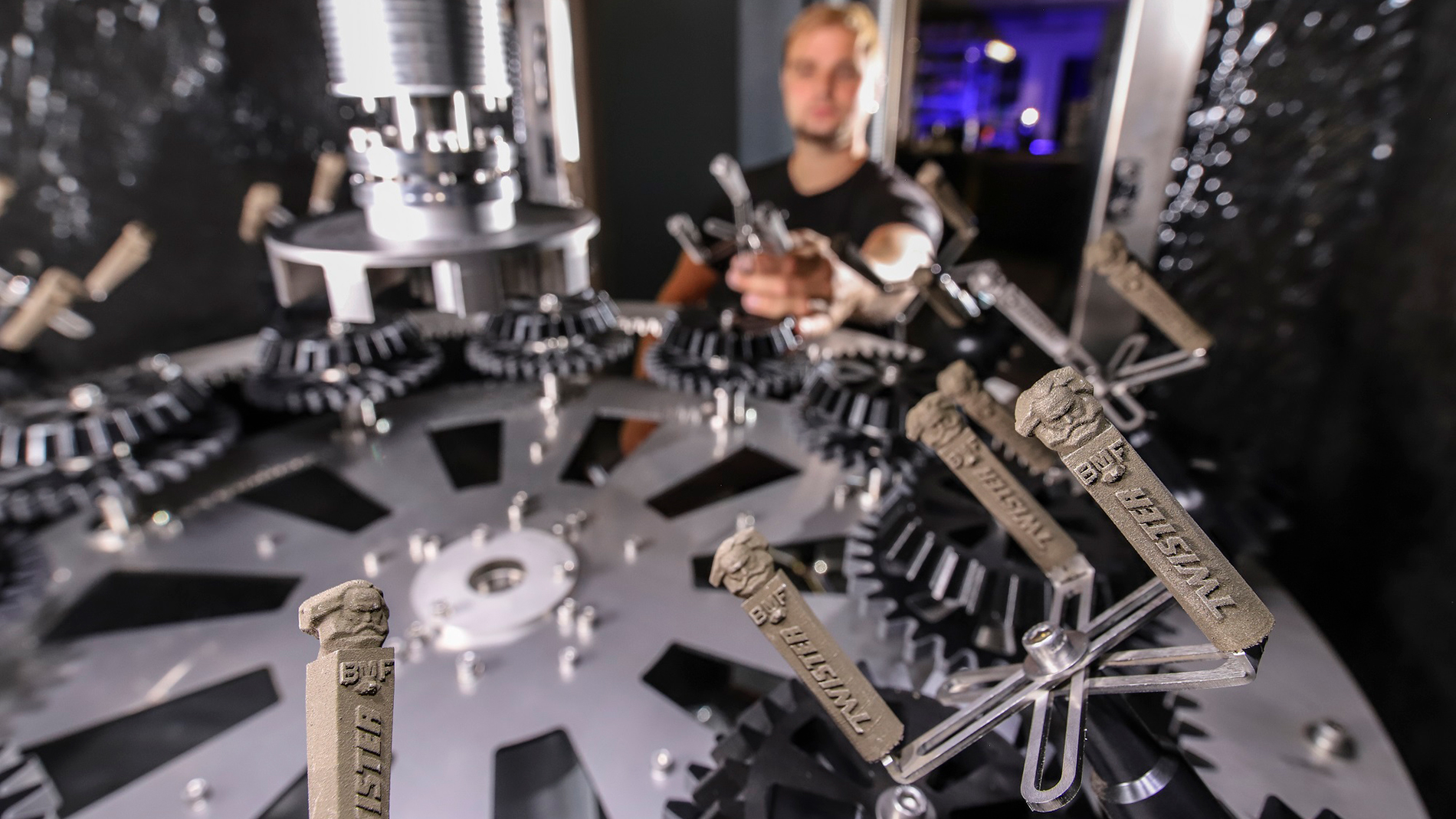

The Smart Surface Control (SSC) technology developed by BMF GmbH makes it possible to integrate blasting surface treatment into automated manufacturing processes for the first time. In close cooperation with renowned universities and manufacturers of measuring equipment, BMF has also developed a standardized measuring method that provides uniform measurements from which manufacturing parameters can be derived. Meanwhile, direct feedback to the blasting or printing system at hand facilitates a self-contained, controlled, and self-optimizing process.

Chemical surface smoothing and coloring of AM plastic parts in just one process step combines the new C2 from AM Solutions. Another innovation from the company is the M4 vor, which is suitable for surface finishing such as grinding, smoothing or even polishing of small and medium-sized metal and plastic parts. Overall, the company's product portfolio focuses on a significantly higher degree of automation and a significant streamlining of the process chain.

Testing at 800 °C

Fast and fully automated high-temperature testing is made possible by Plastometrex, a supplier of mechanical testing technology, with the attachment for its innovative benchtop plastometer. The new module facilitates fast, affordable, and fully automated high-temperature testing of metallic materials by delivering precise stress-strain curves for metals tested at up to 800°C. The PLX Benchtop Plastometer boasts rapid heating and cooling, reaching 800°C in approximately 15 minutes and cooling down just as quickly, which enables swift testing of multiple samples.

Innovation from post-processing wins customers

The young company Rivelin Robotics demonstrates how to be successful with innovative post-processing solutions: After winning the Formnext Start-up Challenge in 2022, Rivelin Robotics will be back in Frankfurt in November with exciting collaborations to talk about: GKN Aerospace and Wall Colmonoy have invested in NetShape, its post-processing solution for metal AM. At Formnext 2023, Rivelin will be showcasing its NetShape robots, which provide an automated solution for metal carrier removal and targeted post-processing.

FURTHER INFORMATION:

Numerous other highlights and premieres for Formnext 2023 can be found in the trade show issue of FonMag.

Tags

- Additive Manufacturing

- Surface treatment

- Formnext News

- Quality management and measurement technology

- Component processing