Text: Pasi Puukko (VTT), Lotta Hepo-oja (VTT), and Markku Lindqvist (Delva), 6 September 2023

A Finnish study recently conducted a life cycle assessment of additive manufacturing compared to conventional manufacturing based on a filtrate nozzle from mining operations.

Additive manufacturing is often considered a sustainable manufacturing technology. Although some features of AM clearly are beneficial in terms of sustainability, there are several studies that show that the energy efficiency of AM technologies is lagging behind that of conventional manufacturing. In specific terms, additive technologies typically consume up to twice as much energy to produce the same output.

Part consolidation refers to an approach in which several parts in an assembly are designed as one piece and manufactured additively, eliminating the need to join and assemble them. In many cases, several functionalities are combined into the same part and the assembly’s functional performance is improved. Significant weight reduction can often also be achieved through part consolidation, which is why this method is particularly popular in aerospace applications. We wanted to study how this approach affects the environmental impact of additive manufacturing and whether it brings its energy consumption balance in line with conventional manufacturing, or even improves on it when considering more complex manufacturing processes and assemblies. In addition, we were interested in examining how parts perform and impact the environment during use.

Case component: a filtrate nozzle

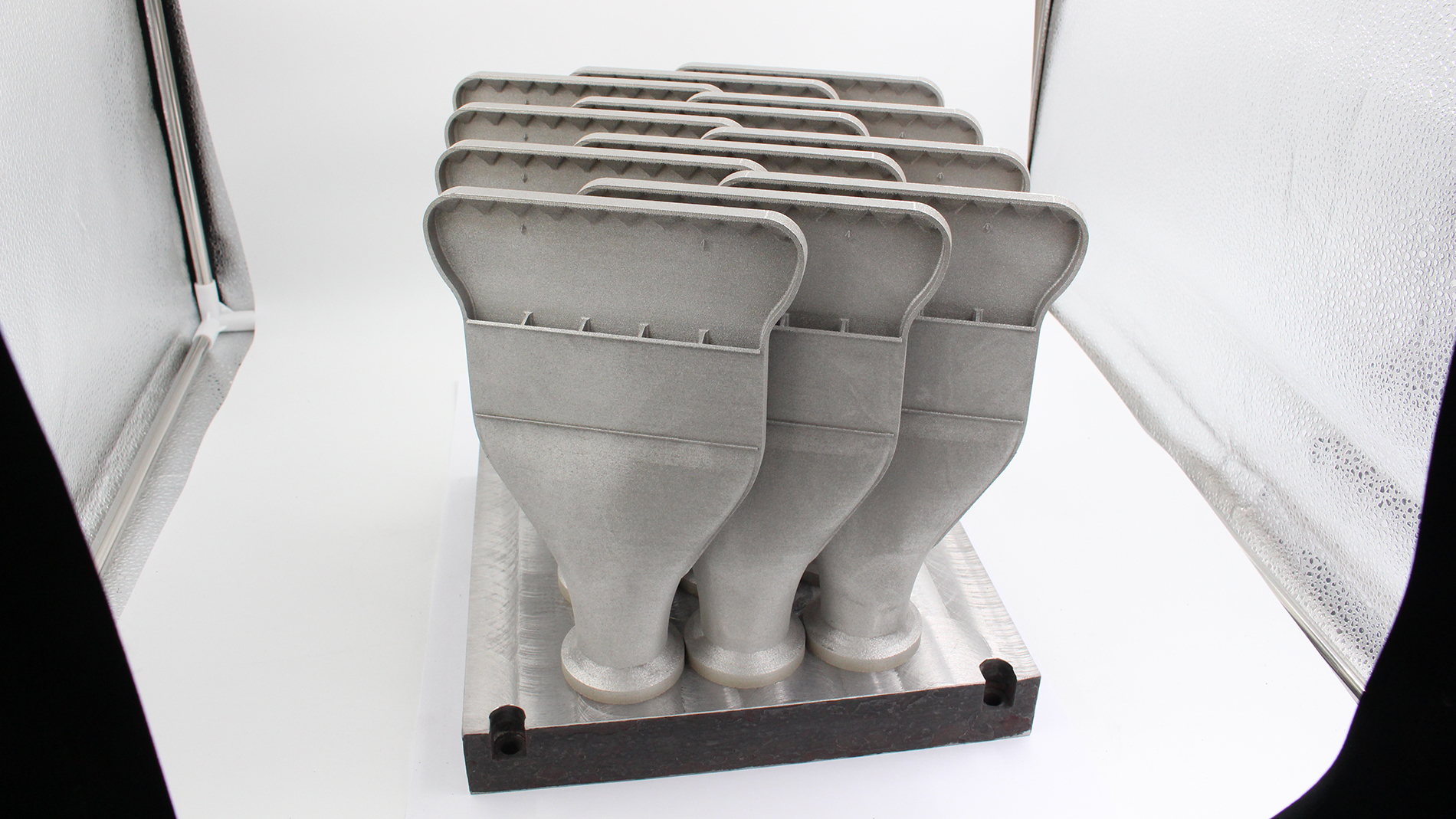

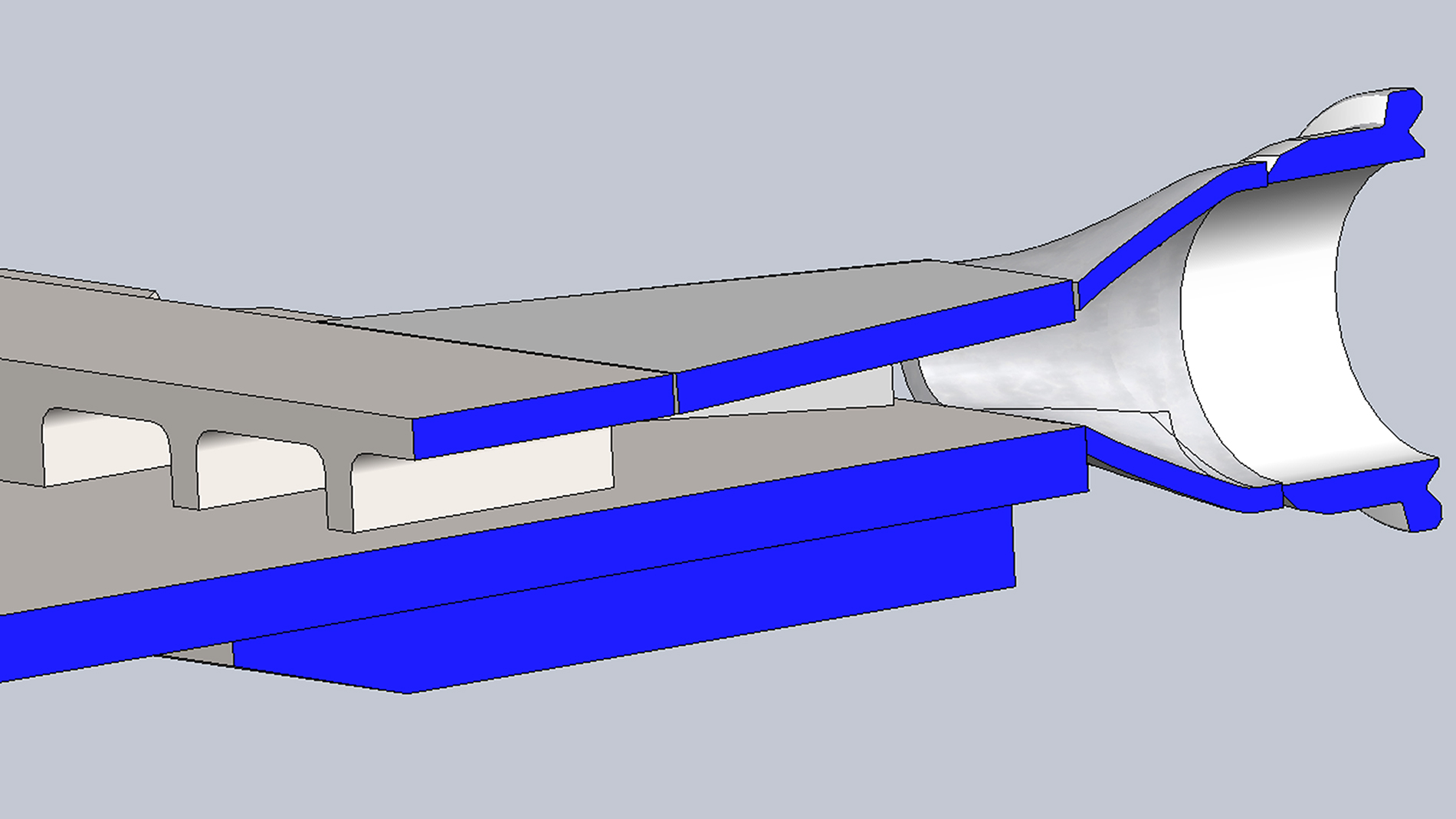

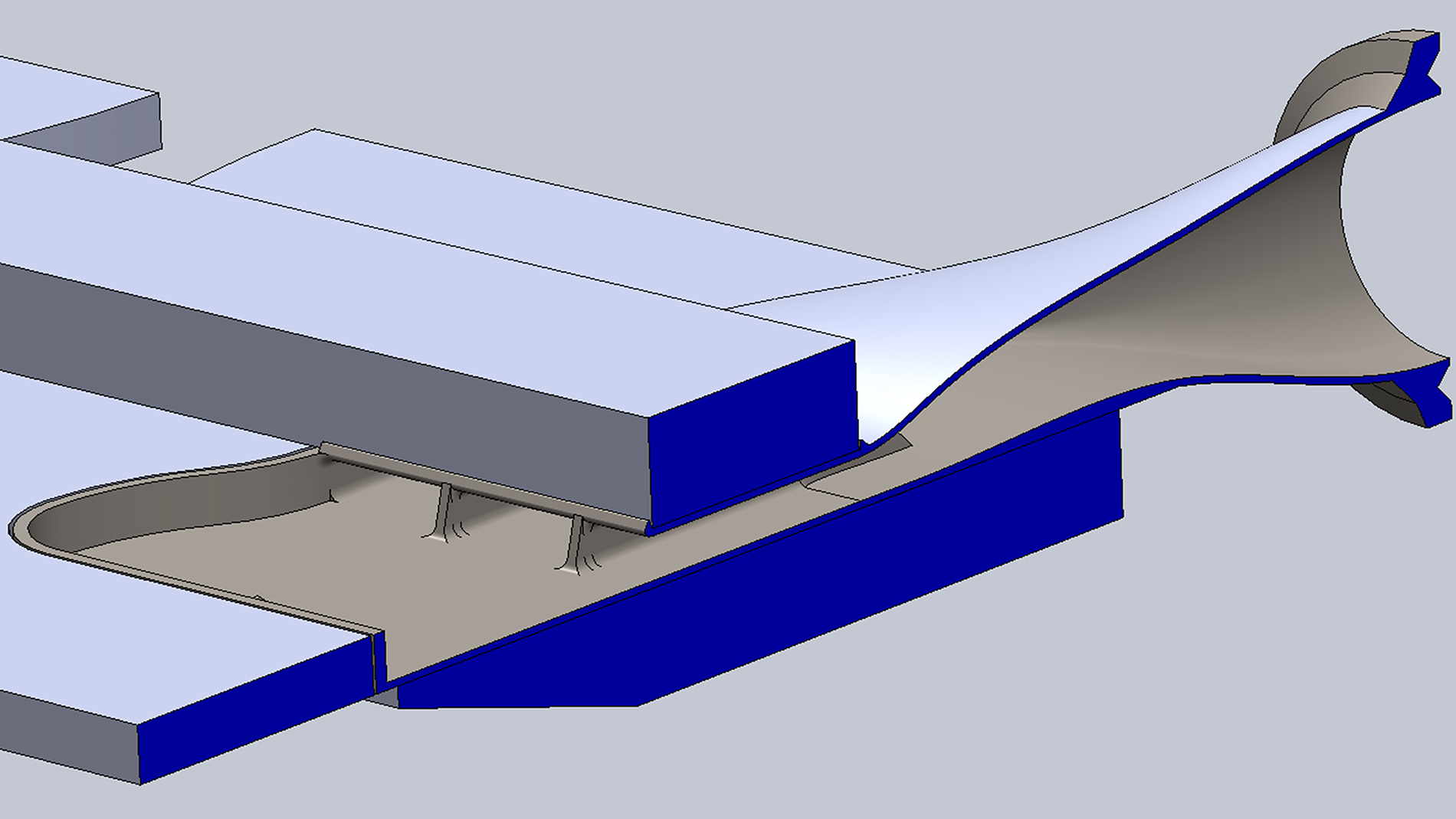

To study the effect of part consolidation, we selected a filtrate nozzle – an essential part of machines used in the mining industry – as our case component. Its main purpose is to increase the dry content of a slurry or similar material. The nozzle, which is made of stainless steel (AISI316L), collects liquid from a filter plate and delivers it to output channels.

Images: Delva

When manufactured conventionally, the filtrate nozzle consists of four separate pieces that are joined together. The pieces are manufactured from several blanks (a metal pipe, a round bar, and a sheet) by cutting and flattening the pipe, machining the round bar with a lathe, laser-cutting and bending the steel sheet, and then assembling the separate pieces with MIG/MAG welding. An additively manufactured version of the same component was manufactured at Delva Oy (Hämeenlinna, Finland) by means of laser-based powder bed fusion (PBF-LB) using an EOS M 290 machine and AISI316L stainless steel as the feedstock material. A batch of 12 pieces was made, and no assembly was required. For this study, the manufacturing was carried out with two different standard parameter sets provided by the machine manufacturer in order to produce 40-µm and 80-µm layer thickness.

A reduced carbon footprint with the right process parameters

We collected essential data from both manufacturing processes. As input data, we used the mass of each material blank; the welding wire, metal powder, and argon gas; and their corresponding transportation distance and mode of transportation. The electricity consumption of each manufacturing process – pipe cutting, tube flattening, round bar machining, laser cutting and bending of the sheet metal, and the welding process – was ascertained as input parameters, as was the electricity consumption of the 3D-printing process and related post-processing steps. The mass of the manufactured components and the waste produced was collected as output data. Life cycle assessment (LCA) was carried out using the software Sulca from the VTT Technical Research Centre of Finland Ltd. following the procedures of ISO standard 14067. The EcoInvent database was used to fill in gaps in the data.

The results indicate that the feedstock material used has a remarkable impact on the carbon footprint of the manufacturing stage, especially in the case of PBF-LB manufacturing. By varying the yield of the atomization process, we then studied two different scenarios related to powder production to better understand its effect. Changing this process parameter in manufacturing also led to a meaningful reduction in carbon emissions in the PBF-LB process. The VTT Technical Research Centre of Finland Ltd. and Delva Oy will both be present at Formnext 2023 (Nordic Pavilion, Hall 11.0, next to the Industrial Stage). Their booths and the Pavilion Stage will provide further details on this and other interesting cases.

FURTHER INFORMATION:

Tags

- Sustainability

- Market reports and studies