In the food industry, the color blue plays an important role. Blue plastics with molded-in color are clearly visible and can be identified in real time on production lines. In this way, they provide predictive support for process safety in a sector where this aspect is particularly critical. For example, blue-colored material makes it possible to identify plastic particles or other debris in food through visual inspection or automatic detection.

That's why the French company Fabulous has developed a molded-in blue polyamide for industrial laser sintering that will be unveiled for the first time at Formnext. This bio-based plastic, Bluecare, also makes it easier to determine the cleanliness of components. As Fabulous explains, spores, mold, and food or cleaning residue are more visible than with other dyed materials. Bluecare is also certified according to the requirements of international regulations on food contact materials, including in line with EU Regulation No. 10/2011.

Unlike other polymers, the PA11 polyamide comes from a renewable raw material source. According to the company, 50 percent of the powder can also be reused, giving it one of the lowest refresh rates in 3D powder printing.

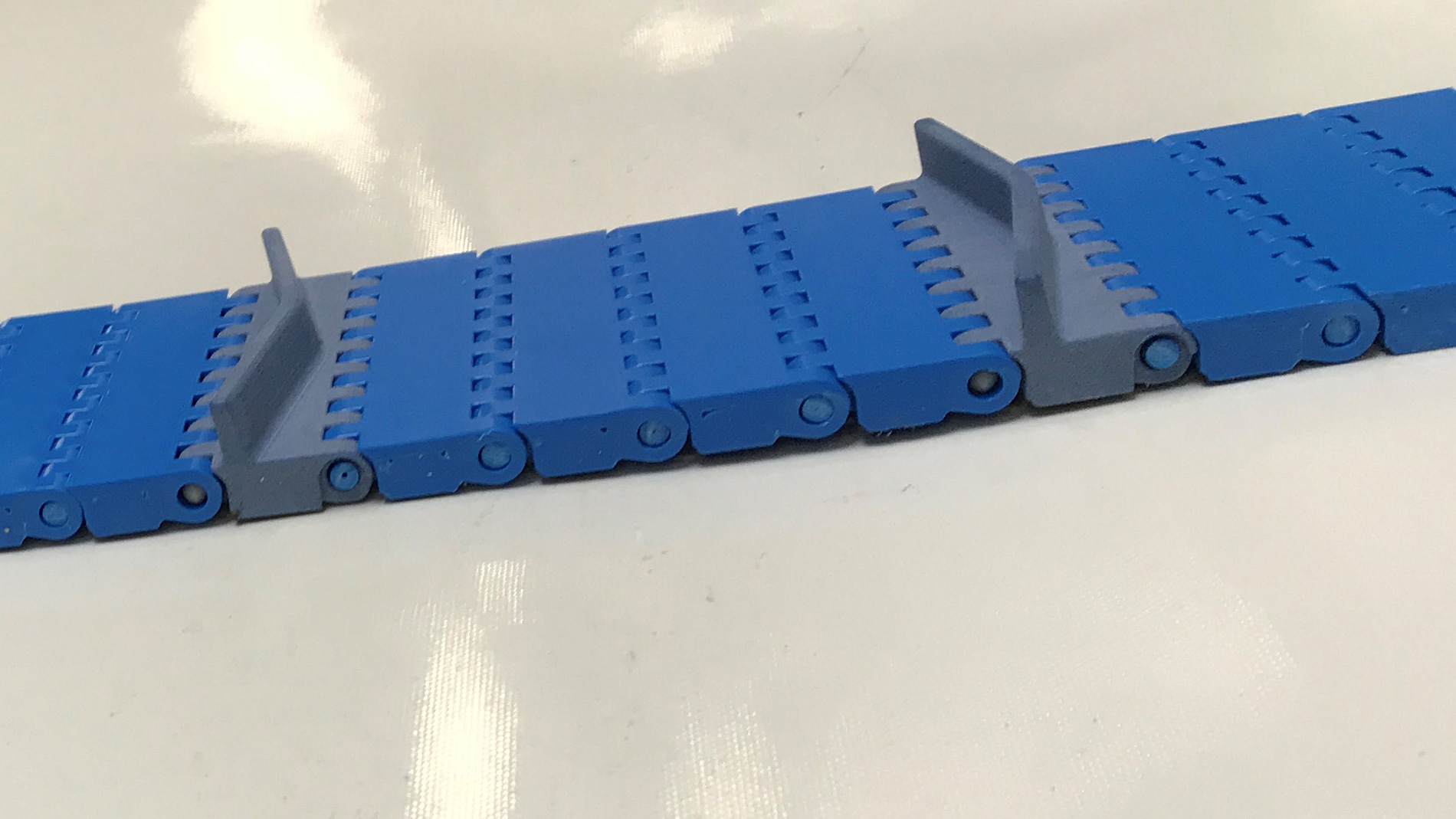

Partner companies have already begun manufacturing components from this material. One of Fabulous’s partners in the Bluecare project was the French print service bureau ID Print 3D, which used the powder to design 30-centimeter-wide modular elements for food conveyor belts. "This allows us to avoid the costly production of a casting mold for a small number of pieces," says Patrice Panchot, managing director of ID Print 3D. Fabulous now has around 10 customers using the material in Europe, and FDA approval is pending for the US and Canadian markets.

Tags

- Materials

- Additive Manufacturing