Text: Thomas Masuch, 17 May 2024

The AM service provider 3Faktur has leveraged automation to establish itself as a leading manufacturer of finished components

When Markus May and his business partner Johannes Zaremba founded the AM service firm 3Faktur around 10 years ago, their intention was to focus on manufacturing prototypes. After a few years, however, the 42-year-old May could no longer see a future in that line of work. The competition was only getting more intense, prices were falling, and more and more companies were acquiring their own in-house 3D printers. “How can a service provider offer real added value that customers can’t find anywhere else?” May found himself wondering at the time.

“For us, series production of prefabricated parts has proven to be the solution,” he says today. Implementing an efficient production process with printers from the same manufacturer and automating it in a holistic manner were key steps along the way. According to May, these changes were also necessary in order to survive in the marketplace as a service provider for finished components. “If it weren’t for automation, our production methods wouldn’t be competitive,” he points out.

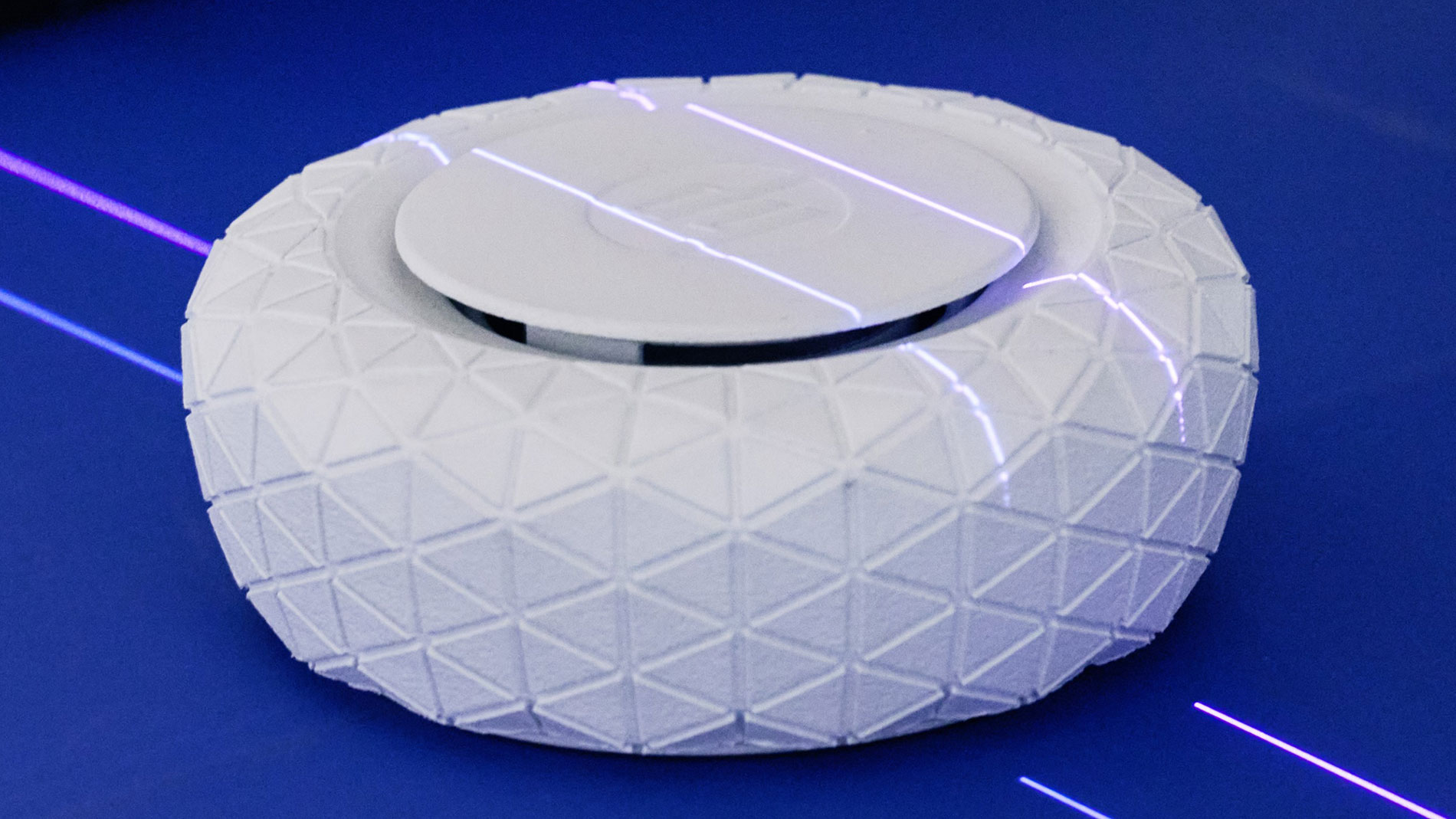

3Faktur automated its operations in 2021 along with AM Flow, a Dutch company that specializes in automation solutions for additive manufacturing. This effort involved integrating component recognition, sorting, and packaging. The resulting system now complements other automation solutions in manufacturing at 3Faktur, which come from the likes of HP, Rösler, and MHG.

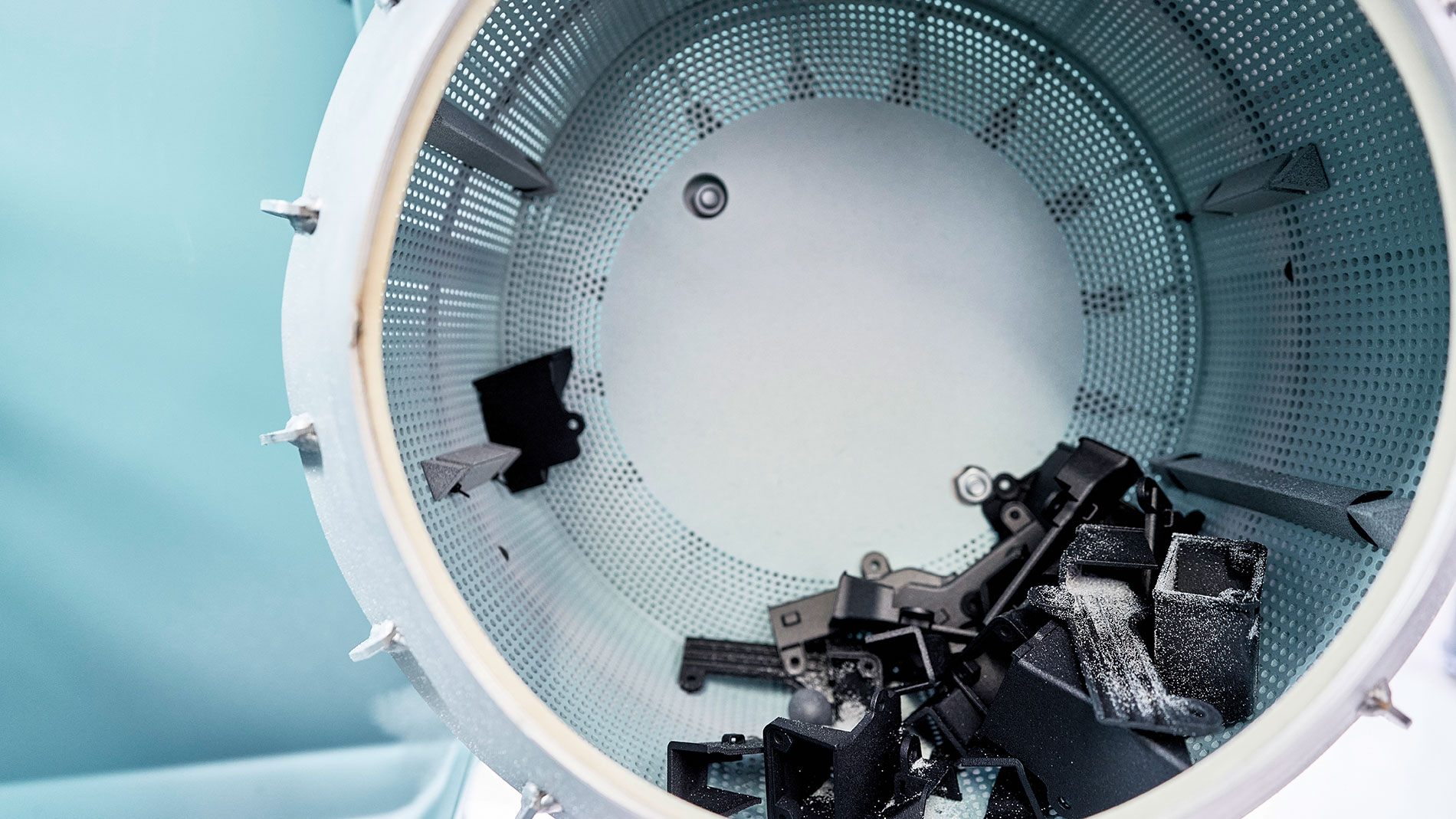

Meanwhile, 3Faktur wouldn’t have been able to pull off this automation upgrade without overhauling its entire IT landscape. “For that purpose, we created our own production management software, which enables us to monitor and control data on every essential production step,” May explains. This made the company a pioneer in its industry and one of AM Flow’s first customers. It also reflects the corporate philosophy of 3Faktur’s co-founder: “For us, it was always important to have the newest technologies at the company,” May affirms. That remains a high priority at 3Faktur, which is currently working as a beta tester alongside another manufacturer on the development of a new machine for cleaning AM parts – one of the innovations set to be unveiled at Formnext 2024.

Housing components, mechanisms, fixtures, and more

Since its foundation in 2014, 3Faktur’s workforce has grown to 12 employees. The company, which is based in Jena, Germany, began making exclusive use of HP printers in 2017 (it now has four) and produces its parts largely from polyamide. The some 2,500 customers it currently serves hail primarily from the mechanical engineering, vehicle construction, and medical equipment sectors. 3Faktur manufactures plastic industrial components like housing parts, mechanisms, and fixtures for them. These days, it rarely produces prototypes. “Our parts are usually built into other things,” May says.

Geometric variance

As for the matter of when automation makes sense for a service provider, May explains that it’s mainly a question of how much variance there is among the parts in question; the quantities produced aren’t all that critical. “When you make 30 to 50 different geometries on your printers, it starts paying off,” he reveals, adding that once a process is stable, orders for additional components are almost sure to follow.

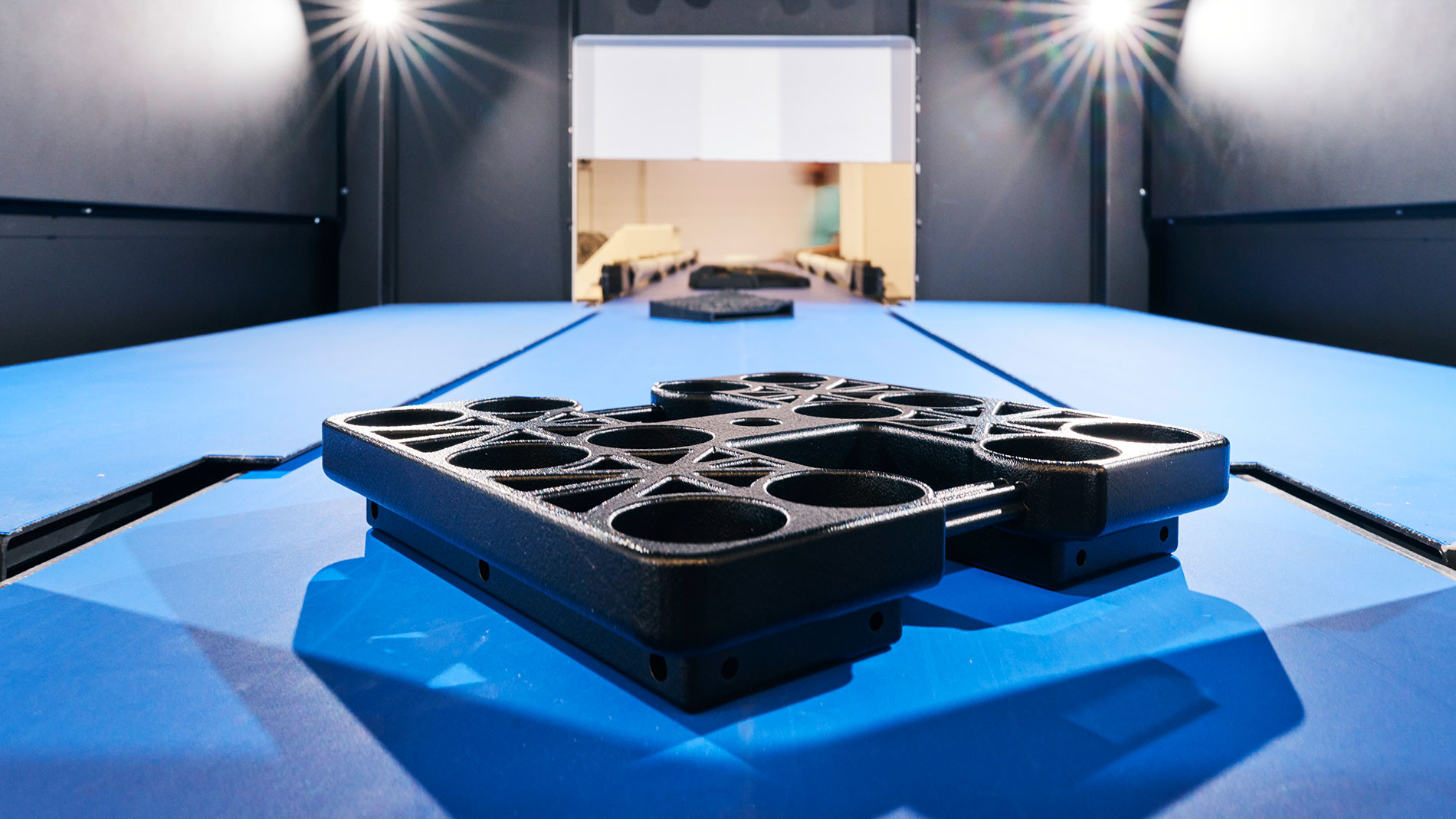

At 3Faktur, every print run results in around 200 parts, which puts the company’s daily production at roughly a thousand. Each individual build contains approximately 15 different geometries. “We mix components of different sizes together for quality reasons,” May points out. “Ideally, parts are arranged so that roughly the same surface area gets illuminated in each layer. That’s difficult to pull off with large components, so we insert smaller parts in between.” This is precisely where May thinks a service provider like 3Faktur has an edge: After all, other companies typically don’t deal with this degree of component variance. As he goes on to explain, however, the trick further down the production line lies in separating parts in an efficient manner. This is no longer a problem thanks to 3Faktur’s automation efforts, which have included implementing a camera-based system for part recognition.

“A lot has changed”

After using the company’s new systems for three years, May has nothing but good things to say about automation – in spite of the cost of acquisition and the monthly fees 3Faktur pays. “For a rather small company like ours, it was a major investment, but we’re reaping major benefits, as well,” he states. 3Faktur’s production operations have become more efficient, and its fully automated process also makes it possible to compile end-to-end quality reports for customers.

“A lot has changed at the company overall as a result; there’s so much more we can do,” reports May, who also points out that automation has paid off in another way, as well. “For the most part, customers are placing their orders on shorter notice, and the number of batches is getting smaller.” May says this makes the capacity to accommodate peaks while maintaining a consistent level of quality – including over extended periods of time – all the more important. “If a customer contacts us again after a few months and wants to order the same parts as before, there can’t be any differences to the previous batches,” he explains.

For May, this is how automation opens the door to more efficient growth. “With systems like these, you can significantly expand production without having to hire more people.”

FURTHER INFORMATION:

Tags

- Services

- Automation and handling