16 May 2022

Is it possible to automate additive manufacturing processes? This question has been one of the most discussed in the industry since AM first made its appearance as a manufacturing technology. Especially during the Covid19 crisis and the associated supply bottlenecks, there were many calls for a realignment of the supply chain. Additive Manufacturing also often came into play here, although it requires a greater degree of automation for the production of higher volumes. This was already a hotly discussed topic at Formnext 2021 - but what is the current situation of automation technologies and how are they implemented in the AM-plastic industry?

Pilot projects for testing automation technologies within an industrial production line have been run by industry leaders to try and break through the current limitations and technological barriers.

For example, the Polyline project, begun in March 2020 and scheduled to run for the duration of three years, was devised with the intention of automating single processes in the AM production line and connecting them from part design to the final product. The technology shall be qualified for larger series in general and the automation shall further increase the quality of the products. The objective is to bring this to market as an end-to-end solution, within what is referred to as a “holistic view” of the automated AM workflow. “You can’t only develop one thing or the other”, says Martin Friedrich, former Project Lead Series Projects Additive Manufacturing at BMW Group, “Everything should be interconnected and fully automated.”

A BMBF (Federal Ministry of Education and Research)-funded consortium of 15 industrial and research partners from Germany has been brought together by EOS to contribute their individual competences to try covering all of the aspects of software and hardware know-how required to overcome the many technological hurdles of automating every step of the production line.

“So far, everything is labor-intensive”

“From the point of view of the supplier, we can see that there’s a high interest in scaling polymer 3D printing technology”, said Marcus Andrä, Product Line Manager Polymer Periphery and Automation at EOS. “The demand for a fully integrated automated production line is very high.”

The reasons why a big OEM like BMW Group would approach the automation of AM processes are very clear. “Currently, everything is labor-intensive”, says Martin Friedrich, Project Lead AM Series Products at BMW Group. “A great share in the production of AM parts today is invested for repetitive processes, such as unpacking the parts. As an automotive manufacturer, we want to be as efficient as we can, and give our employee’s capabilities the best way.”

“A lot of it has to do with costs as well”, adds Paul Osswald, Project Lead R&D for Non-metal Additive Manufacturing at BMW Group. “If AM wants to take the next step and increase production volume the cost needs to decrease, and automation is one way to do it. There’s downtime, you’re dependent on employees to be there. Being able to run the machines productively without anyone being present increases the efficiency which then in turn reduces the final cost per part, and reducing costs is crucial to be able to scale up.”

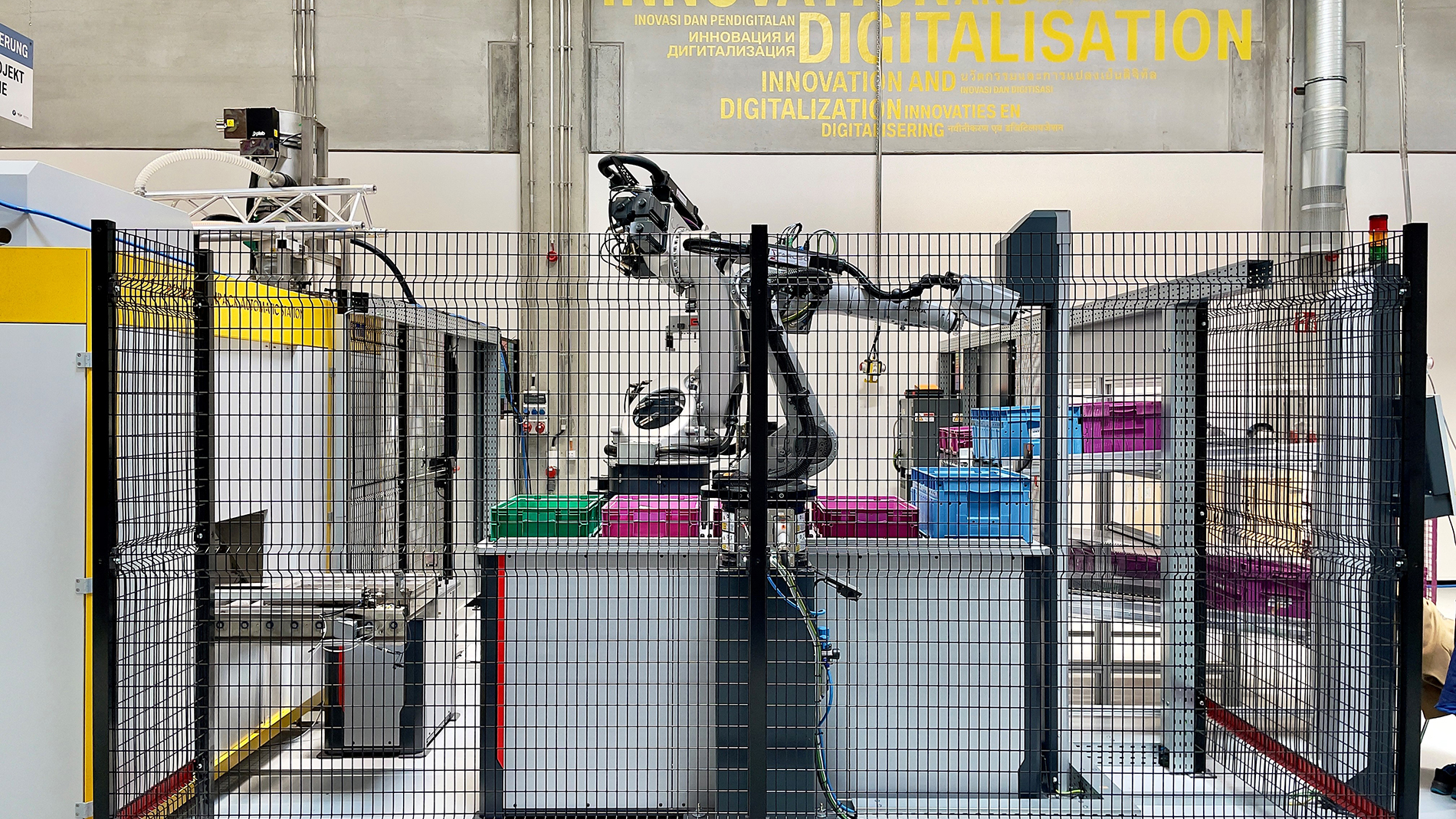

Automation is implemented in the production line through a combination of software, hardware, AI and robotics. In particular, automating a whole production line means to automate the individual machines as well as to automate the communication between them. Machines like the EOS P 500 are fully automated polymer systems able to perform a series of operations such as loading and unloading exchange frames and cooling off the part without any human intervention. Automated powder handling, unpacking, cleaning and post-processing stations all work autonomously, while also being connected by automated transport systems.

Algorithms to make the overall process more efficient

Software is another crucial aspect. Data are collected from the work stations via real-time monitoring and used to develop algorithms to make the overall process more efficient. The part is followed in every stage and can be checked at any time thanks to thermal cameras and sensor data from the machines. As a result of this, quality inspection and monitoring is established throughout the process, rather than at the end.

At the same time, having all the data of all the processes recorded also enables greater traceability. “If a customer from BMW wants to know where all the information of a part that’s been produced is, they can just click the button and get the information right away”, says Andrä.

However, there are still limitations to how the technology can work independently of human operators. This is evident especially in the phase of post-production, where operators still have to set up the machines according to the different structural and design requirements of each specific job. “Currently we can’t adjust to complex geometries and new materials automatically”, says Julius Legenmajer, Senior Product Engineer at DyeMansion. “This means that the process has to be adapted by our experts to the almost limitless variety of 3D printed part geometries and specifications. What we need as a next step would be to have smart machines that can adjust dynamically to changing input parameters and adapting to the limitlessness of AM designs.”

Making this particularly problematic is the fact that the issue seems to be inherent to the nature of automation. “Automation is about repeatability”, commented Oliver Elbert, Head of Additive Manufacturing at Grenzebach. “One of the things that makes AM so attractive as a manufacturing technology, which is that parts can have very specific, customized layouts, is also what makes it so difficult to automate.” What the Polyline project aims to do is therefore to overcome these limitations and have processes that are standardized and repeatable along the entire production line.

Increasing the efficiency and reliability of individual operations

While pilot projects like Polyline are focused on achieving end-to-end automation, automation technology is already used in the industry to increase the efficiency and reliability of individual operations with wide applicability. Andrea Landoni, Product Manager 3D Printing EMEA at Protolabs, explains how as a 3D printing services provider, Protolabs has automated post-processing steps with the intention to cater to a range of different sectors, and for this reason, their main interest for automation lies in the possibility to apply the same processes to many products simultaneously.

Certain post-processing steps, Landoni says, apply to every product. For example, parts produced via SLA or Polyjet processes, which are processes usually employed for prototyping, all need support removal. Parts made with SLS or Multijet Fusion, instead, which are used for finished products as well as small serial production, all need powder removal. On the other hand, some products need more specific parameters and post-processing steps. “For us, it wouldn’t make a lot of sense to spend hours setting the parameters for jobs with very specific requirements”, Landoni said. “What we need is to enhance reproducibility, and reduce time and costs; and the best way to do this is to automate those processes that every part needs to go through.”

Right now, Protolabs has automated machines for depowdering and vapor smoothing. Before this, the cleaning and smoothing of the part was done manually, and it was therefore a much more fallible process. With an automated machine, efficiency is greatly increased, especially in regards to times, that are always consistent, and quality reproducibility, which doesn’t have to depend on the accuracy of the operator.

But at the same time, Protolab’s R&D teams are always on the lookout to include new technologies for automation in their facilities. In Munich, they recently moved to a new, bigger facility, with a view to remodeling their production streams and integrating, step-by-step, upcoming automation technologies. “Although right now, the value of automation for us resides mostly in its application to standard post-processing steps”, Landoni concluded, “there’s no reason why we can’t upgrade our automation technology so as to include a broader spectrum of cases in the future.”

AM TECHNOLOGY:

Additive Manufacturing for polymer - powder bed fusion

Additive Manufacturing for polymer - photopolymerization

A structured overview of the complex and multi-layered world of Additive Manufacturing, the process chain and areas of application is provided by our AM Field Guide.

MORE INFORMATION:

Tags

- Automotive

- Additive Manufacturing

- Surface treatment

- Research and development