Text: Thomas Masuch, 24 October 2023

In the field of synthetics, 3D-printer manufacturers are set to showcase a wide range of innovations and world premieres at Formnext 2023.

New 3D printers and innovative additive technologies are at the heart of every Formnext event, and the 2023 edition will be no different. In fact, there are so many of them this year that we couldn’t possibly fit them into just one article. To give you the clearest overview we can, we’ve divided the area of additive hardware into three sections: metals, synthetics, and other materials.

This article covers breakthroughs in the field of synthetics, which continue to impress with their high level of innovation and range of potential applications. Bosch, for instance, is demonstrating its new printing process for injection molding granulate for the first time; Photocentric is unveiling the world’s largest LCD printer; and Venox plans to present a method of continuous fiber placement in open space. In addition, the start-up Reinforce 3D has developed a technology for reinforcing 3D-printed components with continuous fibers following the actual printing process. And finally, Metrom is set to illustrate the capabilities of modern AM materials by milling 3D-printed metal parts live at Formnext using a miniature milling machine.

Printing “unprintable” materials for injection molding

Bosch Industrial Additive Manufacturing is taking advantage of injection molding granules for AM and will be presenting a corresponding 3D printer for the first time, along with its patented printing process. The company wants to make 3D printing scalable while also utilizing materials that were previously unprintableCurrently, injection molding pellets made of materials such as PA6 GF30 (polyamide with a glass fiber content of 30 percent), PP GF50 (polypropylene with a glass fiber content of 50 percent), and PA6 GF 25 FRT (a polyamide 6 PA blend with 25-percent glass fiber content that is certified flame-retardant) can be printed.

Laying continuous fibers freely in space

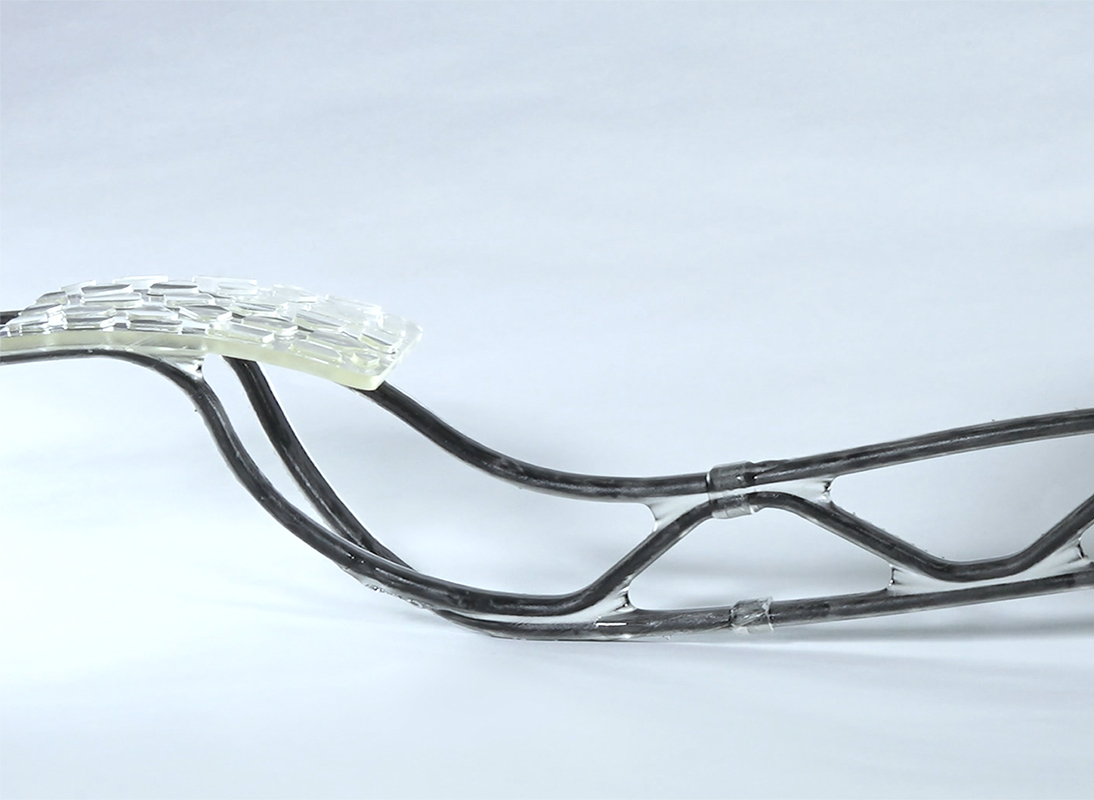

The start-up Venox Systems GmbH will be showcasing the potential of its latest 3D printer, V-REX. The innovation of the V-REX lies in the possibility to lay continuous fibers freely in space. Thanks to its five-axis design, the printing direction can be adjusted in all the fiber directions required, enabling a load-path-compliant fiber layout.

Image: Venox

Image: Reinforce 3D

The world's largest LCD printer

Photocentric will unveil the world's largest LCD printer, the Liquid Crystal Titan, for the first time at Formnext 2023. The Titan combines a build volume of 700 x 395 x 1200mm with high resolution, achieving a pixel pitch of 91 microns across its entire surface. The 8k (7660 x 4320 pixels) screen provides control of over 33 million pixels, which makes it possible to convert huge amounts of liquid into solid material in a short time.

Reinforcing after printing

The Spanish start-up Reinforce3D has developed a new manufacturing technology for fiber-reinforced components, the Continuous Fibre Injection Process (CFIP), and will be showcasing its new Delta machine at Formnext 2023. CFIP reinforces 3D-printed components with continuous fibers by injecting tubular cavities into them. Resin containing the fibers is then injected deep into these cavities, where they strengthen the structure of the part after the resin has cured.

A machine frame straight from the printer

Metrom is demonstrating just how powerful reinforced 3D-printed plastics are. The company will showcase a machine frame for a Metrom Pentapod that was produced using the SEAM (FGF) process. Through additional optimization of the frame’s geometry, the working space was simultaneously increased by a factor of 1.5. Production costs were also reduced by 50 percent and the turnaround time for the frame was shortened from 3.5 weeks to just one. At Formnext 2023, Metrom will mill a 3D-printed metal part on the machine.

Image: Metrom

FURTHER INFORMATION:

Numerous other highlights and premieres for Formnext 2023 can be found in the trade show issue of FonMag.

Tags

- Additive Manufacturing

- Formnext News

- Component processing