Text: Thomas Masuch, 7 November 2024

Good training and the right know-how are the basis for successful work, and that’s no different in additive manufacturing. To support the transfer of AM expertise that is urgently needed in many areas, exhibitors at Formnext 2024 will be presenting new training courses. Certification is also crucial for many AM projects, as the industry is constantly developing new standards. This year’s trade fair will thus be showcasing new solutions for companies that want to have their AM production facilities certified, for example.

Many companies that use 3D printing on an industrial scale need to think about quality assurance, as well. Very precise systems are often required for the inspection of additively manufactured components or AM powder materials, which is another area where Formnext 2024 visitors can discover exciting innovations.

Advancing AM training in all industries

Ampower has just announced the launch of AM Academy GmbH, which represents the strategy consultancy’s aim to advance AM education across all industries. AM Academy will offer a comprehensive suite of services, including self-paced online courses, live training sessions, and guided programs, each of which will be designed to meet the needs of professionals at all levels. Headquartered in Hamburg, Germany, the company is led by Benjamin Haller and operates across the globe.

Certification of AM production facilities

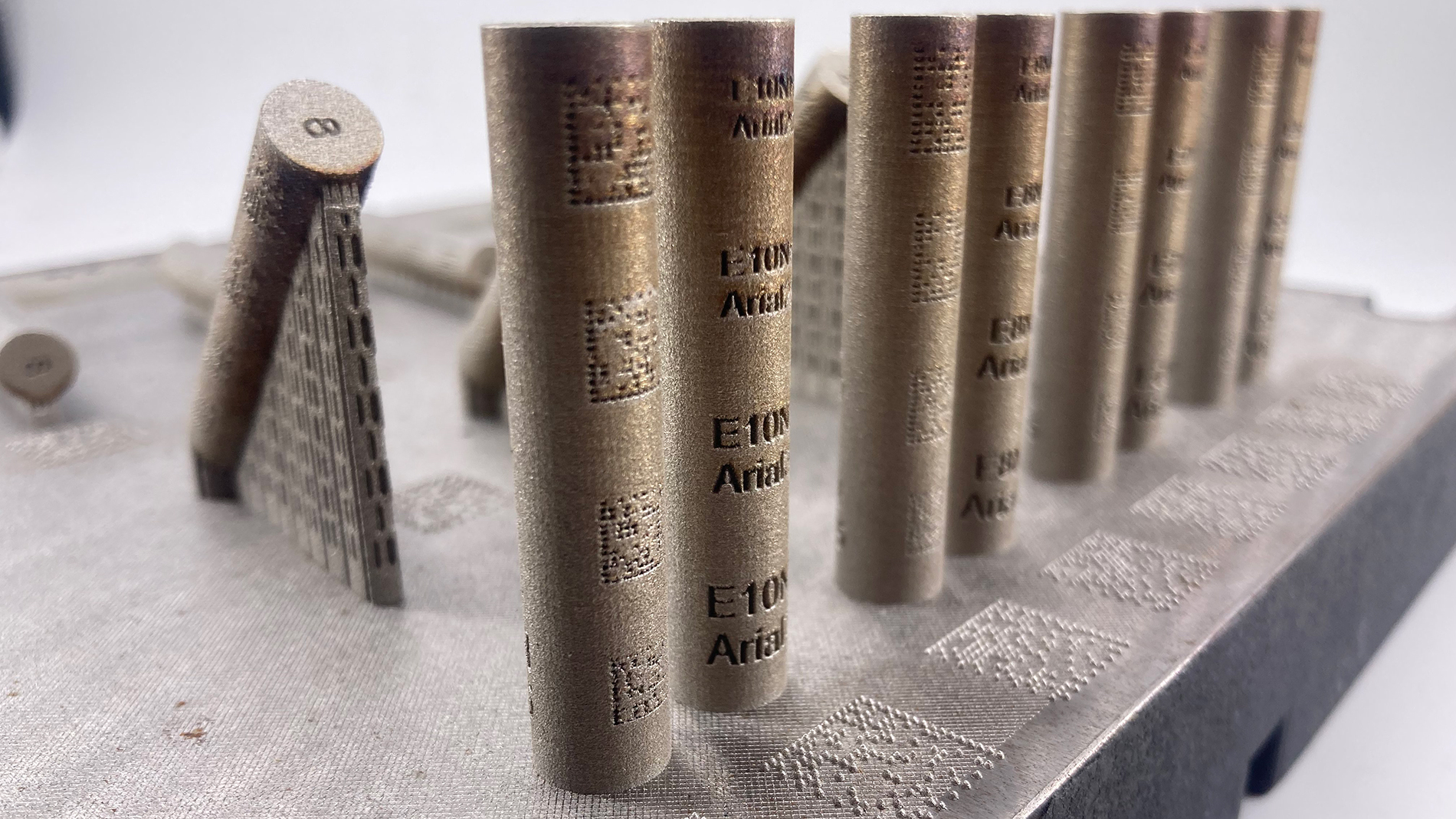

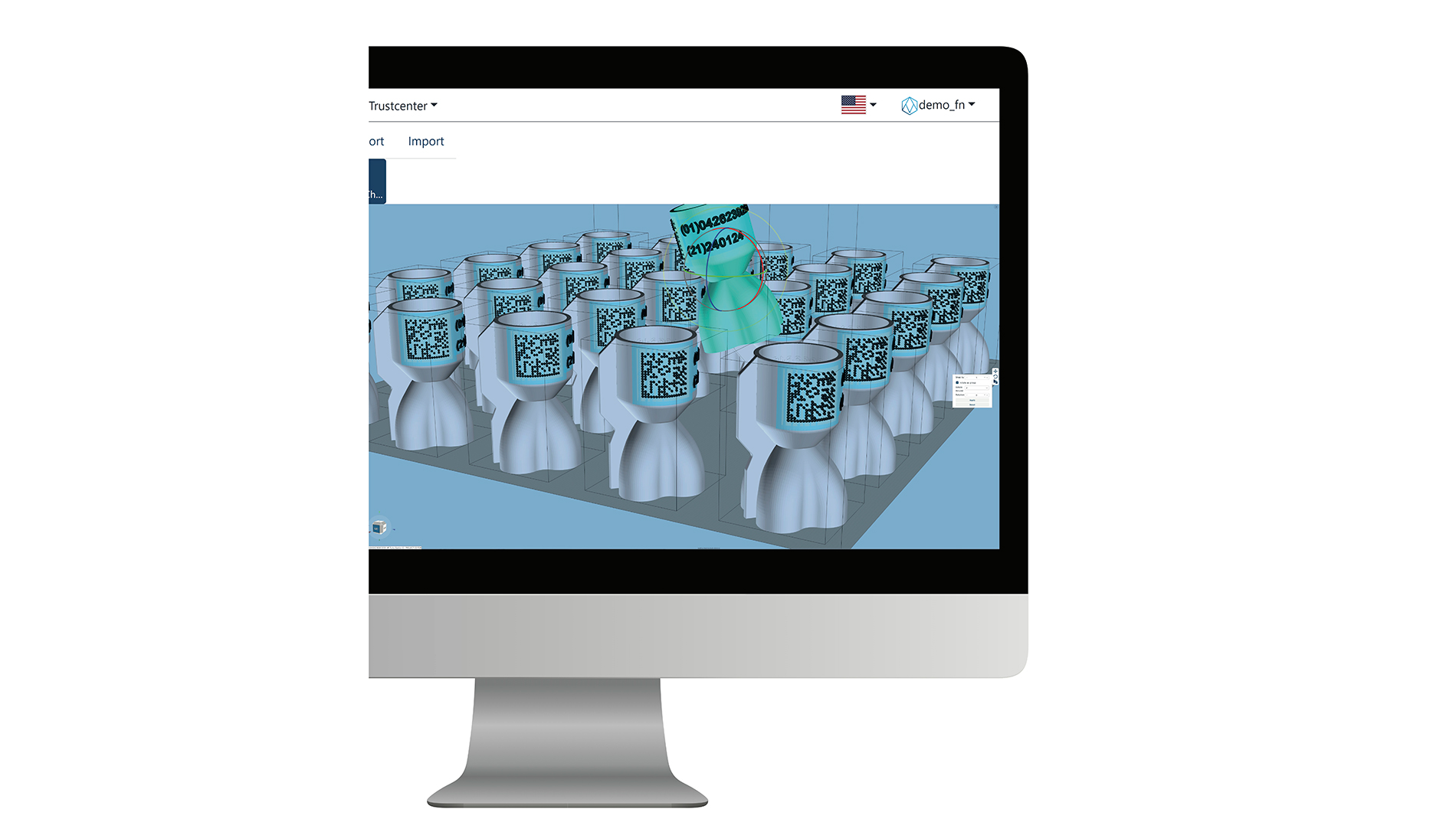

Providing easy access to AM-specific certifications and testing services, ensuring reliable traceability – Additive Marking and TÜV Nord are presenting solutions and methods that are designed to build trust in AM technology. The focus of the two companies' presentation will be on the certification of AM production facilities in accordance with the new international standard DIN EN SO / ASTM 52920:2023. This standard specifies strict requirements for the structural and process organization of AM production facilities and defines framework conditions for reproducible, high-quality series production.

Images: Additive Marking

Measuring the envelope density of solids

The latest innovation from Anton Paar is an accessory set for MCR rheometers, which enables companies to use the rheometer platform to measure the envelope density of solids. The modular design of the MCR Evolution rheometer also allows mechanical tests, tribological measurements, dynamic mechanical analyses (DMA), and all common standard rheological tests to be carried out. This makes it possible to determine the envelope density of solids in the sample size range of 0.3 cm³ to 25 cm³ using a reusable, free-flowing displacement powder.

For microelectronics and nanotechnology

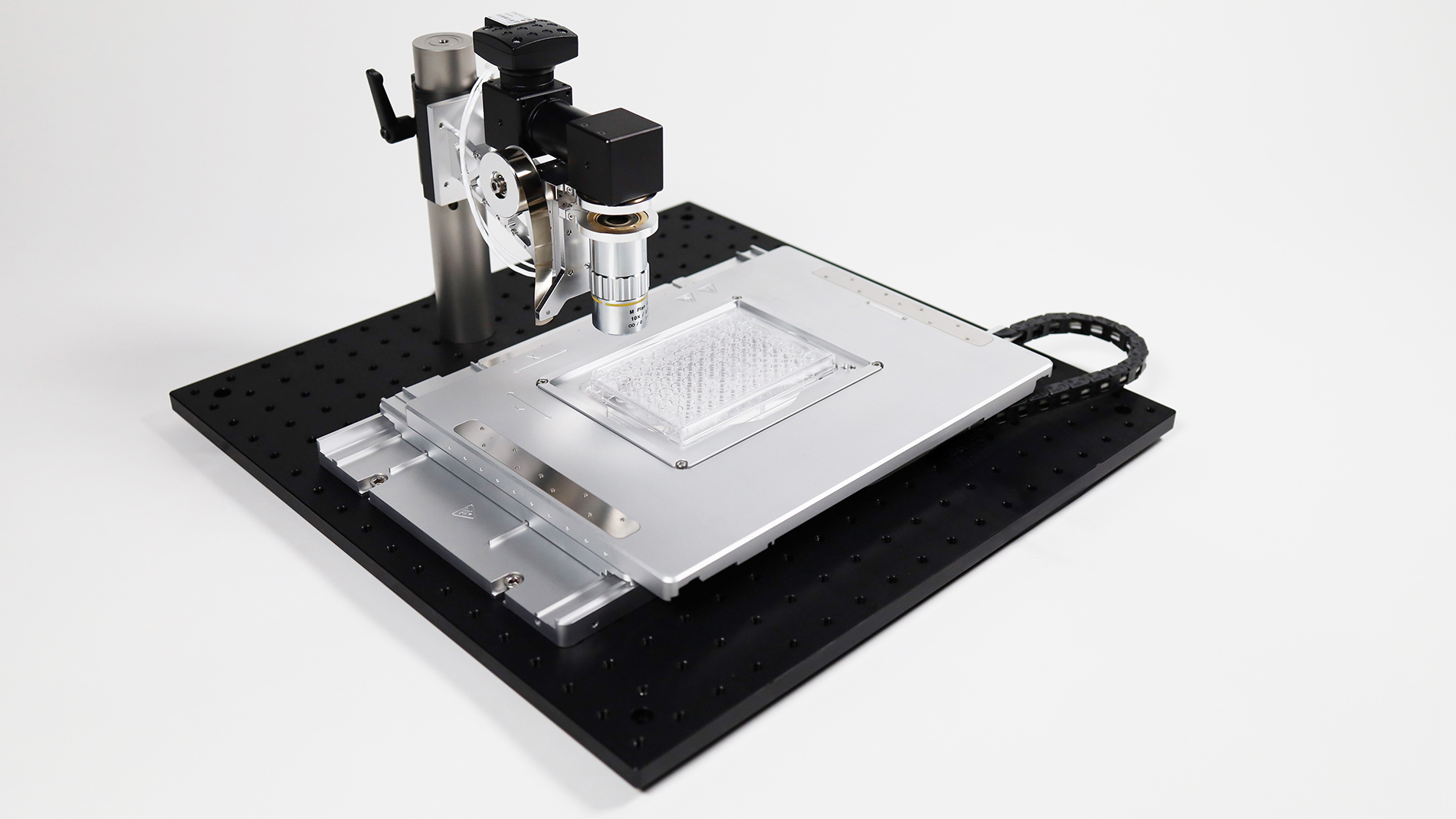

The SmarAct Group from Oldenburg, Germany, is presenting its new SOM-MS-180150M microscopy stage at Formnext. The stage features electromagnetic direct drives and has been specially developed for applications in microscopy, nanotechnology, and industrial manufacturing. It has a travel range of 180 x 150 mm² and a movement accuracy in the sub-micrometer range. The SOM-MS-180150M can also be used in material science, microelectronics, and optics manufacturing.

FURTHER INFORMATION:

You will find all the companies mentioned at Formnext 2024:

Additive Marking and TÜV Nord: Hall 11.1, Booth D28

Ampower: Hall 12.0, Booth B61

Anton Paar: Hall 12.1, Booth G118

SmarAct: Hall 12.1, Booth A85

Tags

- Quality management and measurement technology