3 September 2024

New industrial 3D printers demonstrate the AM industry's drive for greater efficiency.

With various recently introduced machines, the AM industry is confirming the trend towards specialized applications, significantly improved efficiency, and ultimately, lower production costs. Stratasys and Roboze, for example, are promising greater efficiency and increases of more than 60 percent in printing speed with their new printers. The examples below also show that the medical technology and dental sector continues to drive the development of the AM industry (for more, read our latest medical background report).

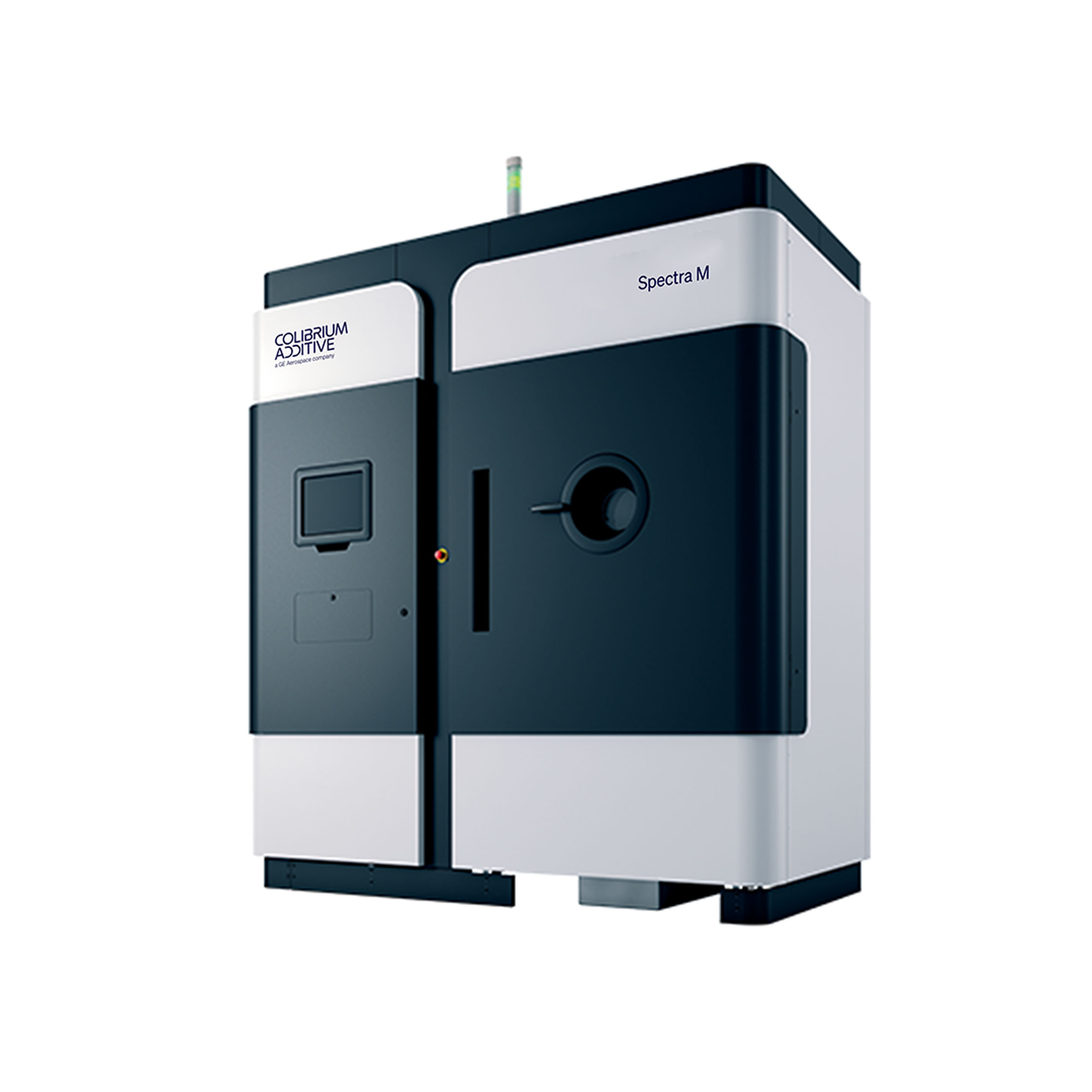

More efficiency for orthopedic implants

The new Spectra M electron beam fusion printer (EB-PBF) is Colibrium Additive's answer to the demand for EB-PBF printers with smaller build volumes. With a volume of 270 x 430 mm and a beam power of 4.5 KW, the Spectra M is aimed in particular at manufacturers of medical and orthopedic implants who, according to Colibrium Additive, want to further reduce the cost per part.

“Spectra M is our direct response to our constant dialog with customers, particularly additive super users in the orthopedic implant industry,” says Oscar Angervall, senior product manager at Colibrium Additive.

The Spectra M is equipped with EBMControl 6.4 and compatible with Point Melt, Powder Supports, and Plate Free technology, as well as with the materials Ti6Al4V Grade 5 and Ti6Al4V Grade 23. The Spectra M is available to order now, with first deliveries expected in early Q1 2025.

Aligners, crowns, and bridges at even higher speeds

The Stratasys DentaJet XL is designed to further improve dental lab productivity and reduce costs with its larger resin cartridges, large print tray, super-high-speed mode, and minimal post-processing workflow.

With this printer, Stratasys is targeting digital dental labs that need to deliver high volumes of orders without compromising on quality. “It’s the most efficient solution we’ve developed to date for producing high-precision crowns and bridges, implant and aligner models, and surgical guides simultaneously on a large scale,” raves Ronen Lebi, vice president of Stratasys Dental.

The DentaJet XL can print two materials simultaneously, and by introducing new print modes and larger cartridges, Stratasys promises to reduce the cost per part by up to 67 percent.

“The new super-high-speed mode has allowed us to increase our production of clear aligners by almost 50%, without additional labor and at a significantly lower cost per part,” says Prof. Armando Razionale from Airnivol, which was one of the first customers to use the solution in Europe.

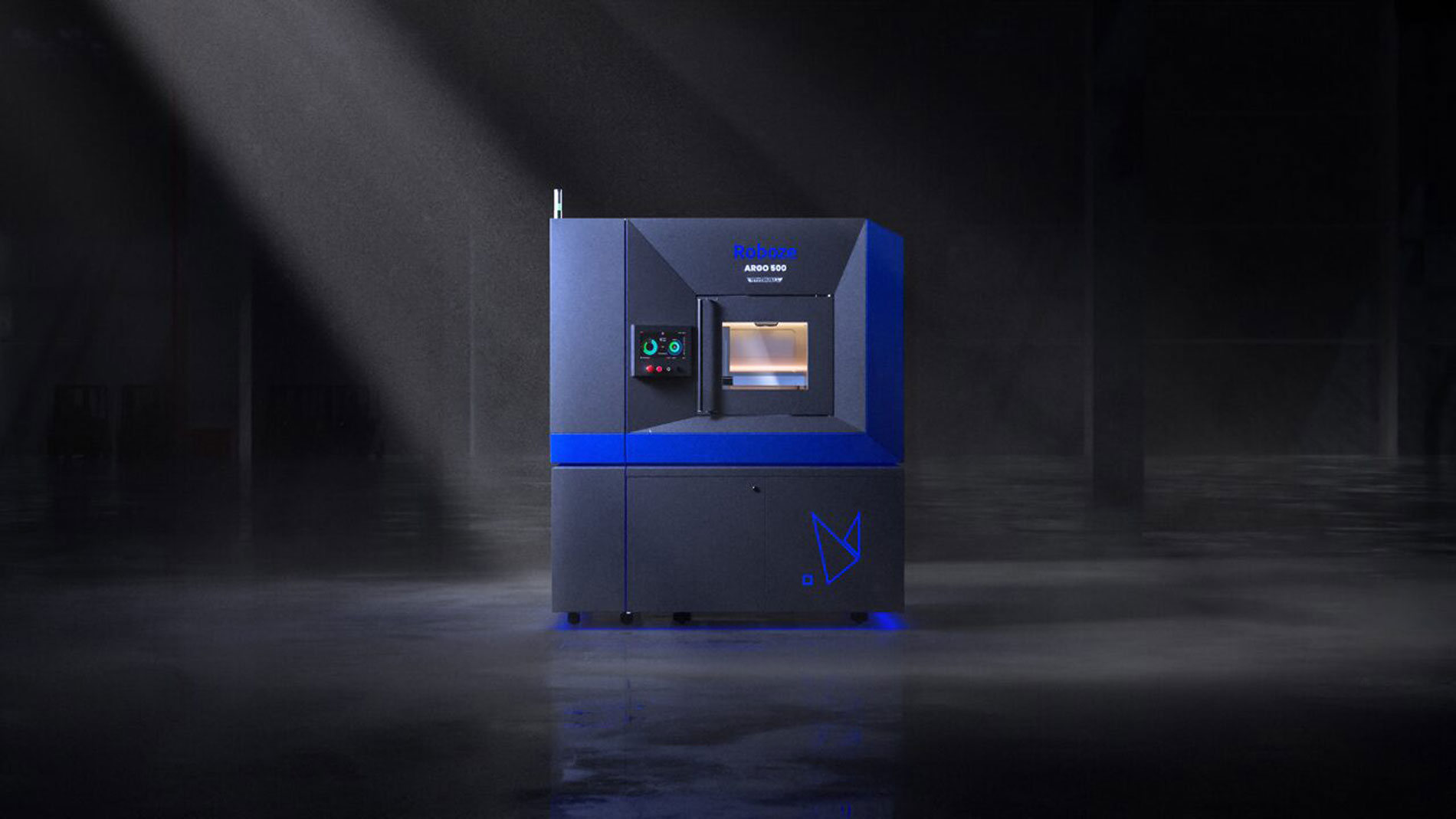

Better material flow for “superpolymers”

With the Argo 500 Hyperspeed, Roboze has introduced a new printer for “superpolymers and composite materials” that features new and patented technologies. In particular, Roboze cites the PolyFlow X system, which enables an extremely fast and controlled material flow that can reduce production times by up to 62 percent.

Another feature is the Smart Gcode printing mode. In this mode, the system can process a variety of special plastics, such as PEEK, Carbon PEEK, ULTEM AM9085F, Carbon PA PRO, and PEKK, which Roboze claims are “as robust and durable as metal”.

Tags

- Dental technology

- Additive Manufacturing

- Medical technology