16 May 2022

Seiko Epson Corporation has developed an industrial 3D printer that can use commonly available third-party materials. 3D printers with these features will have uses in a far wider range of applications, including in the production of parts for final products.

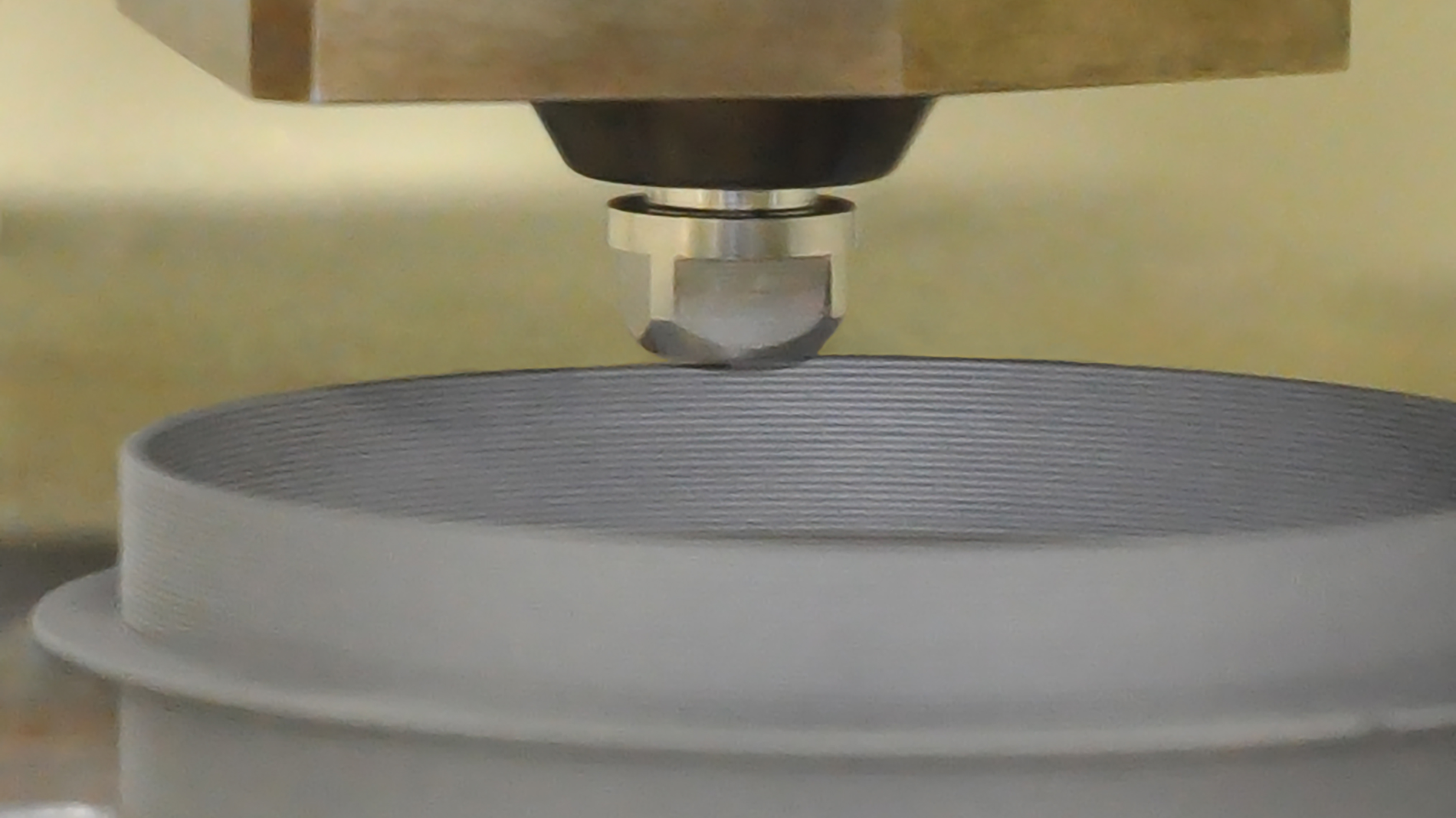

Epson's newly developed 3D printer employs a new material extrusion method that is achieved using a flat screw (an inline screw with a flattened configuration) like that found in Epson's injection molding machines. This extrusion method enables the printer to be used with a variety of common third-party materials, such as resin or metal pellets, which are generally available at lower cost than other materials, environmentally considerate biomass pellets, and PEEK materials, which can provide high heat resistance. The amount of material injected is controlled by regulating the pressure within the head and by regulating the action of a valve in concert with the modeling speed.

The temperature at the surface of a piece being printed must also be controlled in order to obtain the required strength. To achieve this purpose Epson employs a unique mechanism. Epson is aiming to commercialize the printer after first making needed refinements while utilizing it internally to volume-produce certain parts for commercial and industrial equipment.

FURTHER INFORMATIONEN:

Tags

- Additive Manufacturing

- Mechanical and plant engineering