1 November 2022

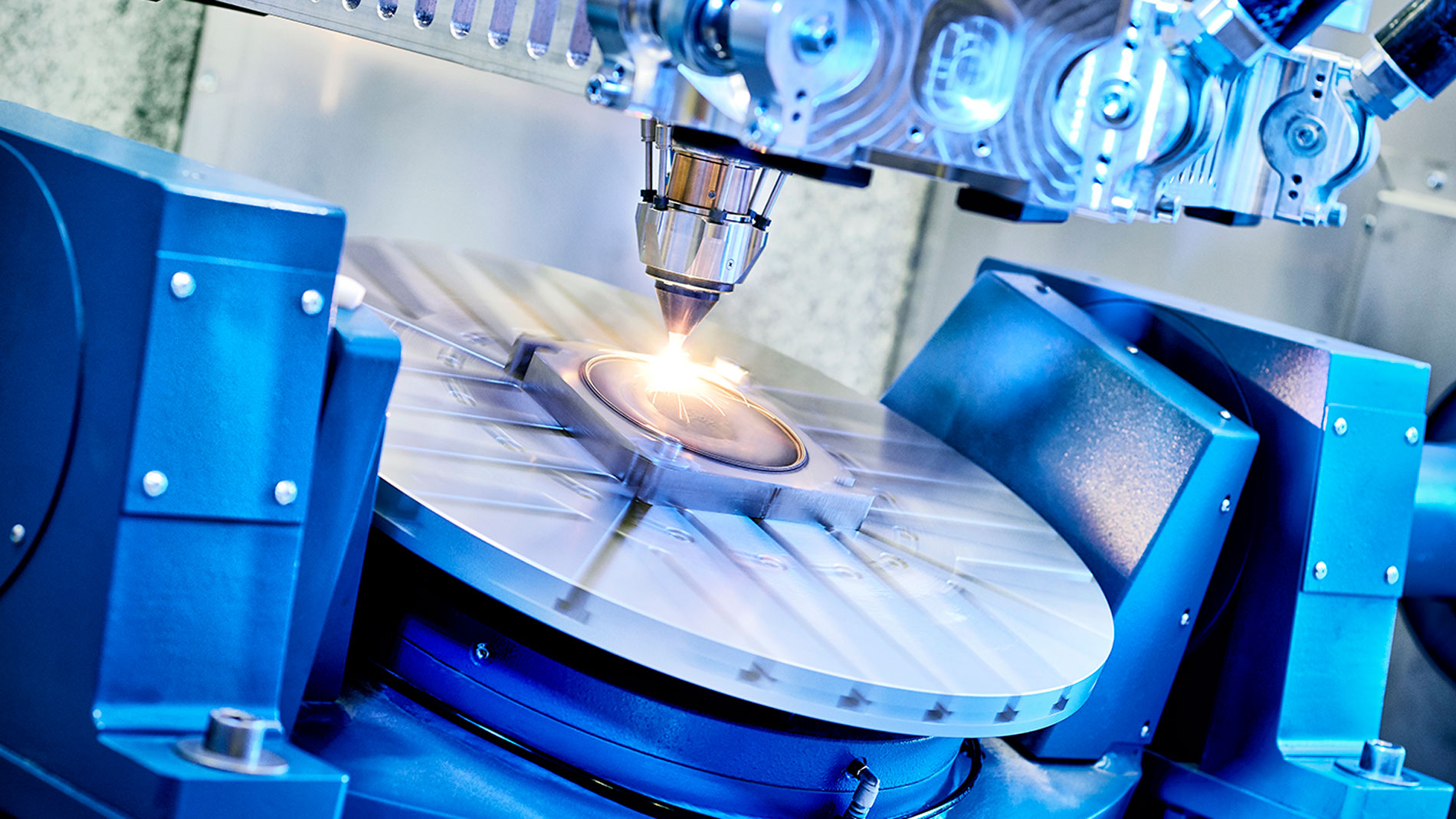

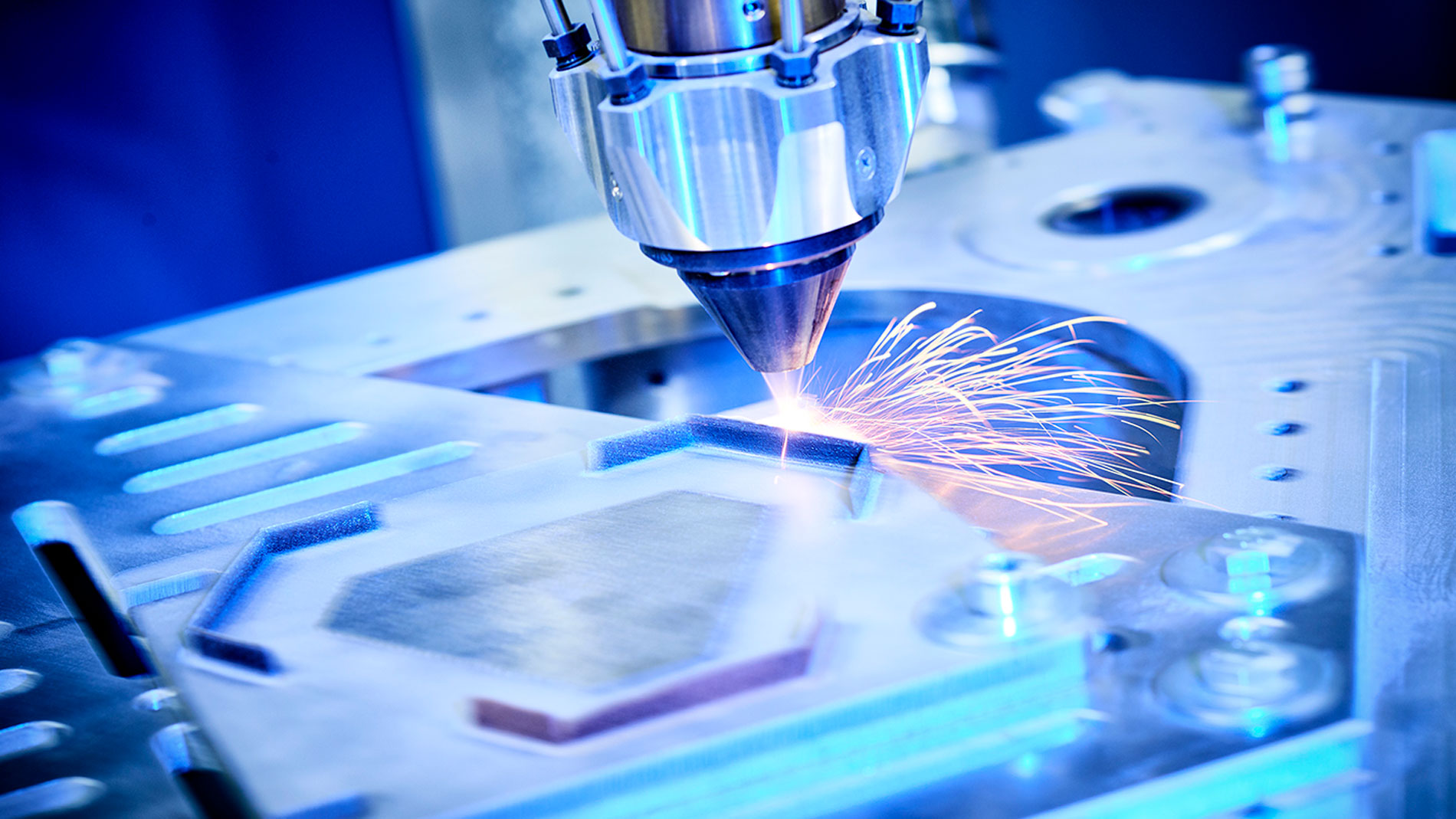

With the Dynamic Material Deposition process developed by Ponticon, alloys of any elemental composition can be deposited on metallic and ceramic components. In contrast to conventional laser deposition methods, in the DMD process the metallic powder is already molten when it reaches the surface of the substrate upon which it is deposited in successive layers.

Ponticon will introduce its new pE3D system for Dynamic Material Deposition (DMD), a process developed for additive manufacturing, coating and repairing complex-shaped metallic workpieces. According to Ponticon, the new system combines high process speed with utmost precision and flexibility in terms of the choice of alloying elements.

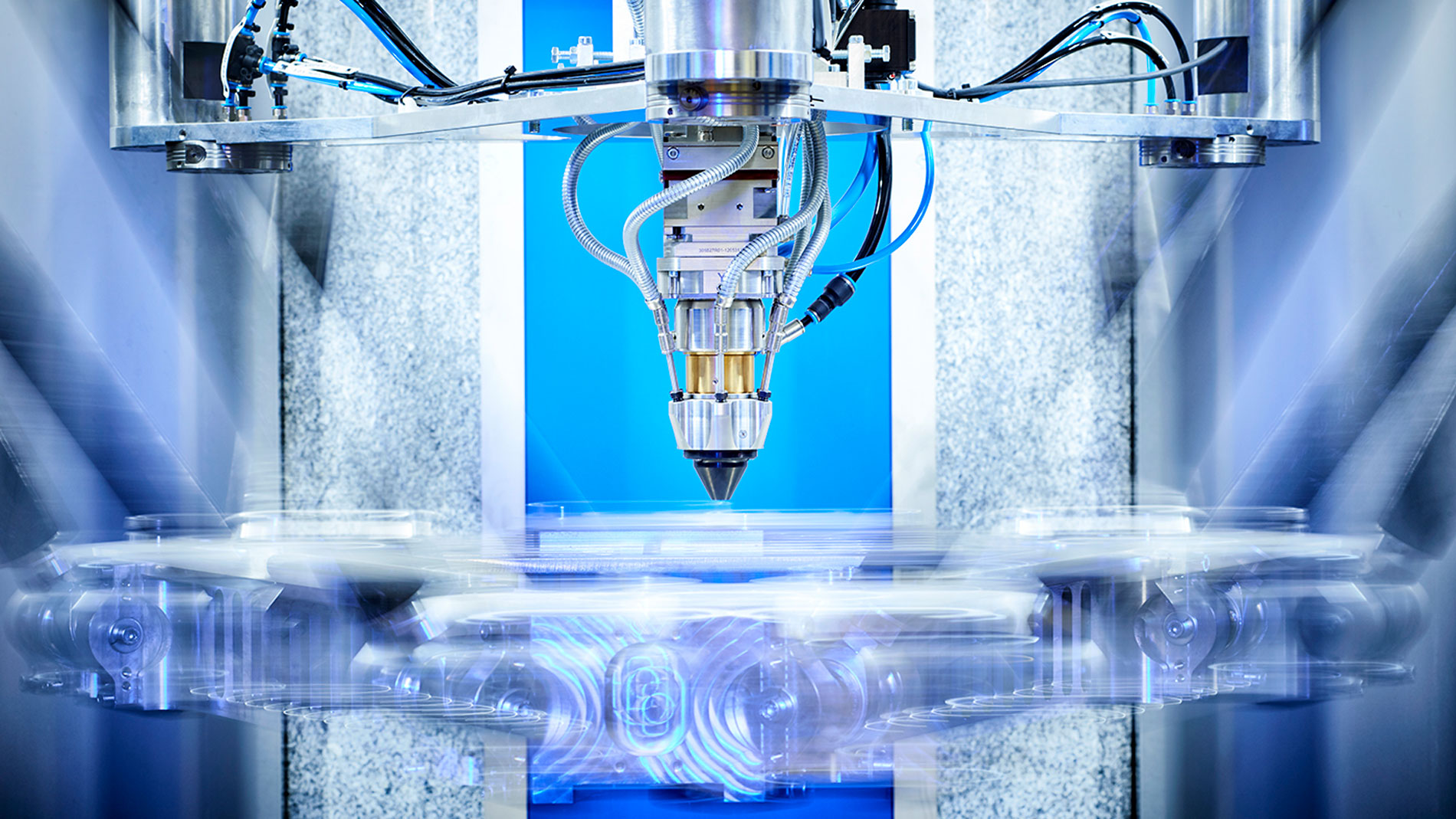

At Formnext, Ponticon will showcase a pE3D system of five-axis design. Its high-speed parallel kinematic system is equipped with an additional turning and tilting device to be able to deal with the most complex of geometries. In its standard design, the machine can handle component weights of up to 500 kg.

When the system is used for pinpoint repairs of components damaged as a result of broken-off metal or worn metallic surfaces, the sensors initially capture the as-is component geometry. Based on these data, the CAM software plans the path for the repair process, which requires the nozzle and the workpiece carrier to be precisely aligned to one another. Once in the aligned position, the system starts to apply the new material onto the workpiece. As the heat transfer into the base material is minimal, the material properties of the repaired components are not affected during the process.

"Our pE3D machines have passed the acid test in various near-industry-scale projects performed by several renowned research institutions. 2023 will see the first machines go into operation in industry," says Tobias Stittgen, Managing Director of Ponticon GmbH.

Ponticon at Formnext 2022:

Hall 12.0, Booth D39

Tags

- Additive Manufacturing

- Formnext News