14 December 2023

Starting with the production of bronze manifolds for the cooling water supply of a marine engine, MAN Truck & Bus is embracing 3D printing through Replique’s production platform to manufacture spare parts on-demand.

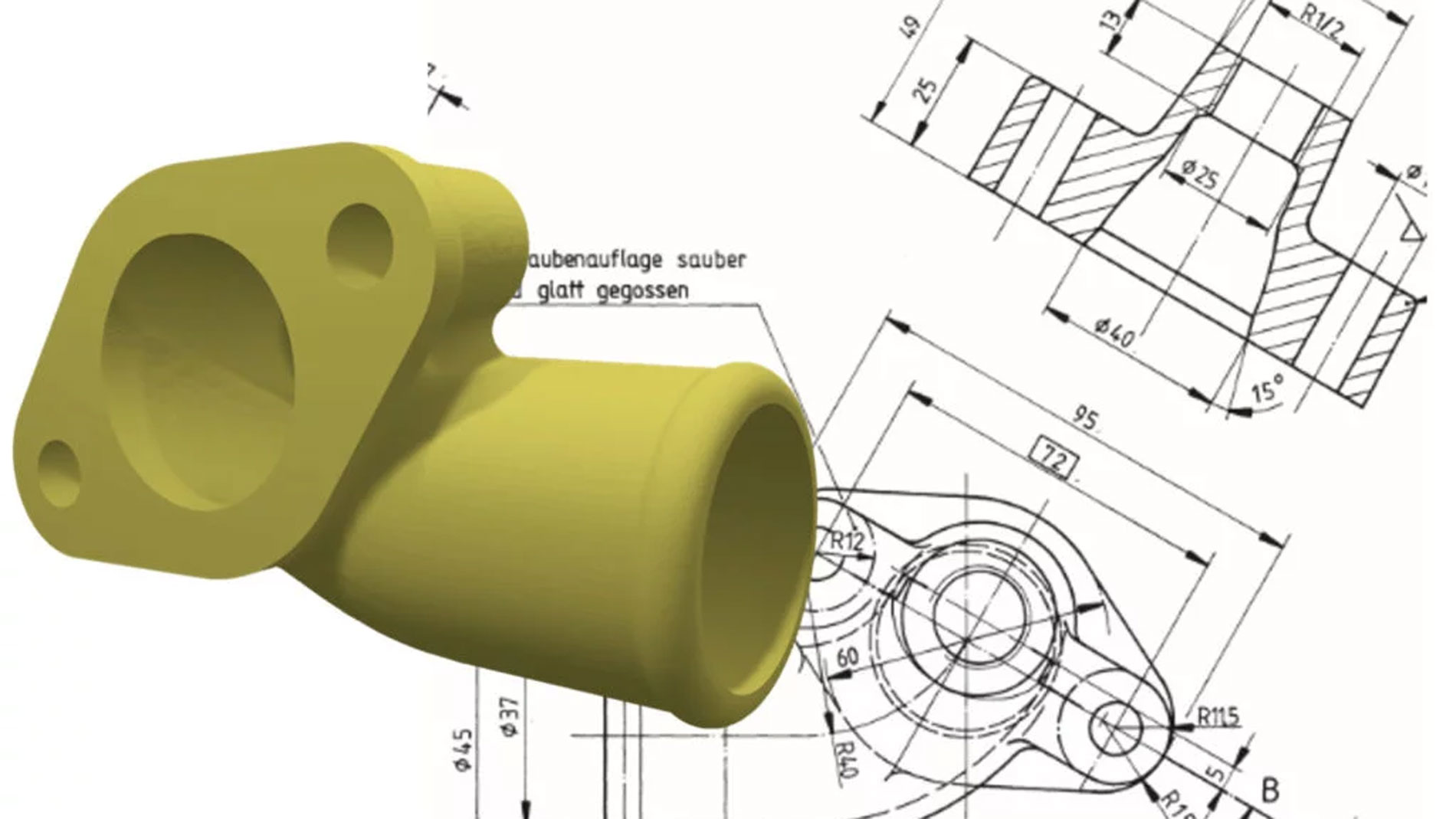

MAN faced the challenge of urgently having to acquire 10 bronze manifolds for the cooling water supply of a marine engine that were no longer in stock. The casting mold for this critical component was unavailable. Conventional procurement methods involving the creation of models, casting, and mechanical machining would have been both time and cost-intensive. MAN, therefore, sought an alternative solution to meet the short-term demand, one that also met the high technical requirements for this highly stressed component.

In collaboration with its material partners, Replique selected a material (m4p Brz10) that was technically equivalent to the original material. The parts were 3D-printed (via SLM) by a local 3D printing service from Replique’s network of more than 85 partners worldwide. From MAN’s initial inquiry to the delivery of ready-to-install parts, only about 7 weeks passed.

Images: Replique

Tensile tests conducted at MAN’s Central Material Technology department revealed that the chosen material actually exhibited better technical properties than the original. The use in practice of these parts was also successful, leading MAN to place an additional order for 10 units. Also, a further 3D printing project is already in the process of being realized.

MORE INFORMATION

Tags

- Services

- Offshore and marine