31 October 2022

Location-independent use and flexible manufacturing: The Mobile Smart Factory wants to write a special story in the field of hybrid manufacturing. And the developers promise the simplest possible operation - hybrid manufacturing at the push of a button, so to speak.

This push of a button is delivered by 1A Technologies in cooperation with Moduleworks GmbH. Using the HY5CAM software, components are to be manufactured and repaired both additively and subtractively, regardless of the kinematics and technology used.

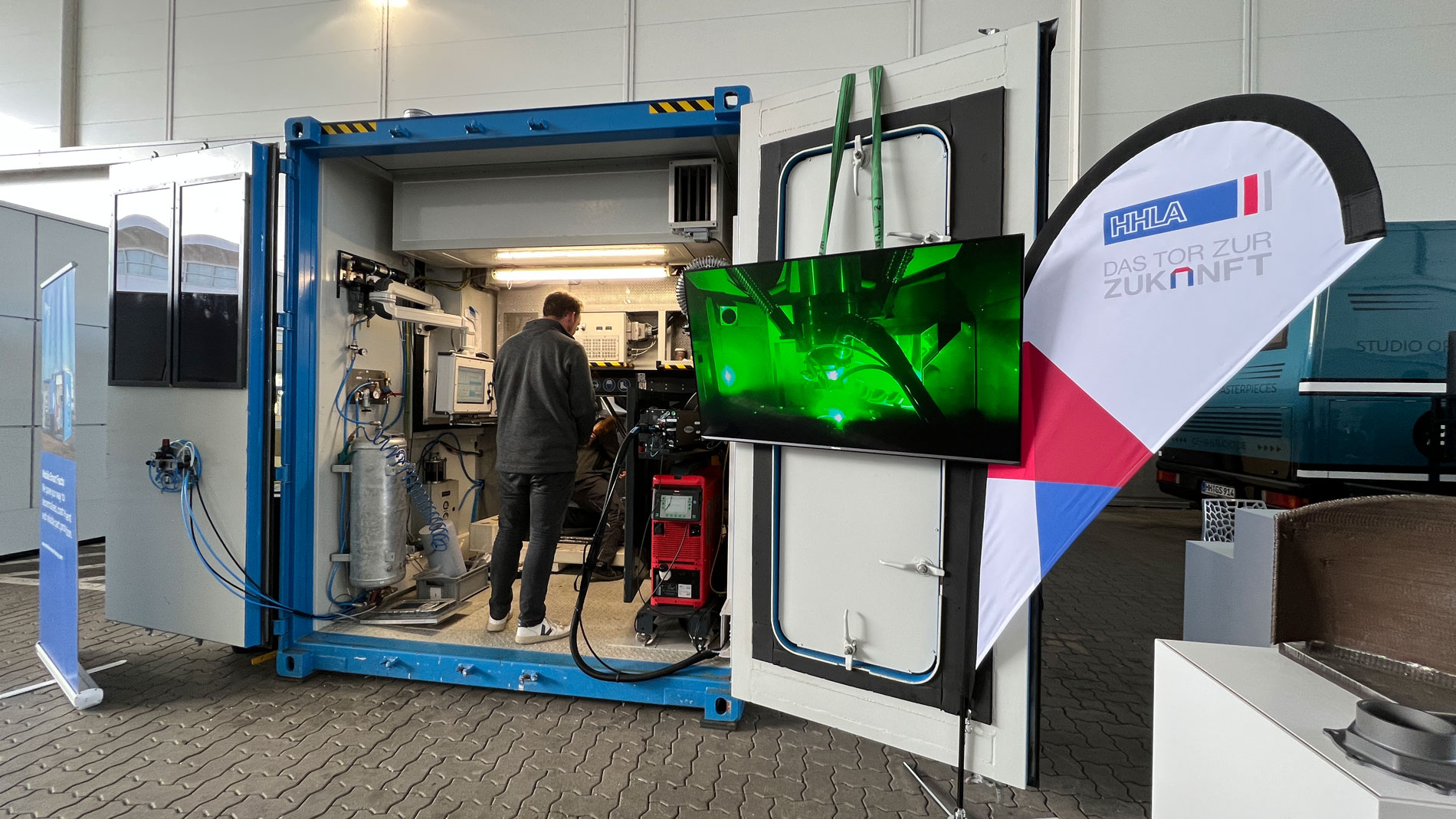

The cooperation started with a customer project with Bionic Production GmbH: The "Mobile Smart Factory" is a production environment in a container. This allows components to be manufactured at the customer's site or on the way there (by ship or rail), regardless of outside conditions, using only an external power supply of 63 amps. The WAAM process or Wire-DED is used in combination with milling including automatic tool change.

1A Technologies sees applications for the Mobile Smart Factory primarily in the rapid delivery of small quantities of individual components. One example is the housing of a windshield wiper motor of an ocean-going vessel, which had to be replaced due to corrosion in order to be able to guarantee the safe continuation of the journey.

After a CAD model of the component had been created in the container, additive and subtractive programming followed using HY5CAM. Manufacturing took place at the heart of the Mobile Smart Factory: a hybrid parallel kinematic 6-axis machine tool of the type P700 from Metrom Mechatronische Maschinen GmbH. The WAAM process was followed by mechanical milling and drilling tool machining on the same machine.

The companies involved at Formnext 2022:

1A Technologies: Hall 11.0, Booth C41

Moduleworks: Hall 11.0, Booth A29

Bionic Production: Hall 11.0, Booth B48

Tags

- Additive Manufacturing

- Offshore and marine