15 July 2022

The dental industry was one of the first to recognize and leverage the benefits of additive manufacturing. Bridges and crowns have already been 3D-printed since the turn of the millennium. The quality of the systems, processes, and materials involved has continued to improve in the interim, ushering in a significant increase in applications. As a result, the market's growth has rarely fallen into the single digits. Additive manufacturing now accounts for around U.S.$2.4 billion in revenue in the field of medicine and dentistry according to Wohlers Report 2022.

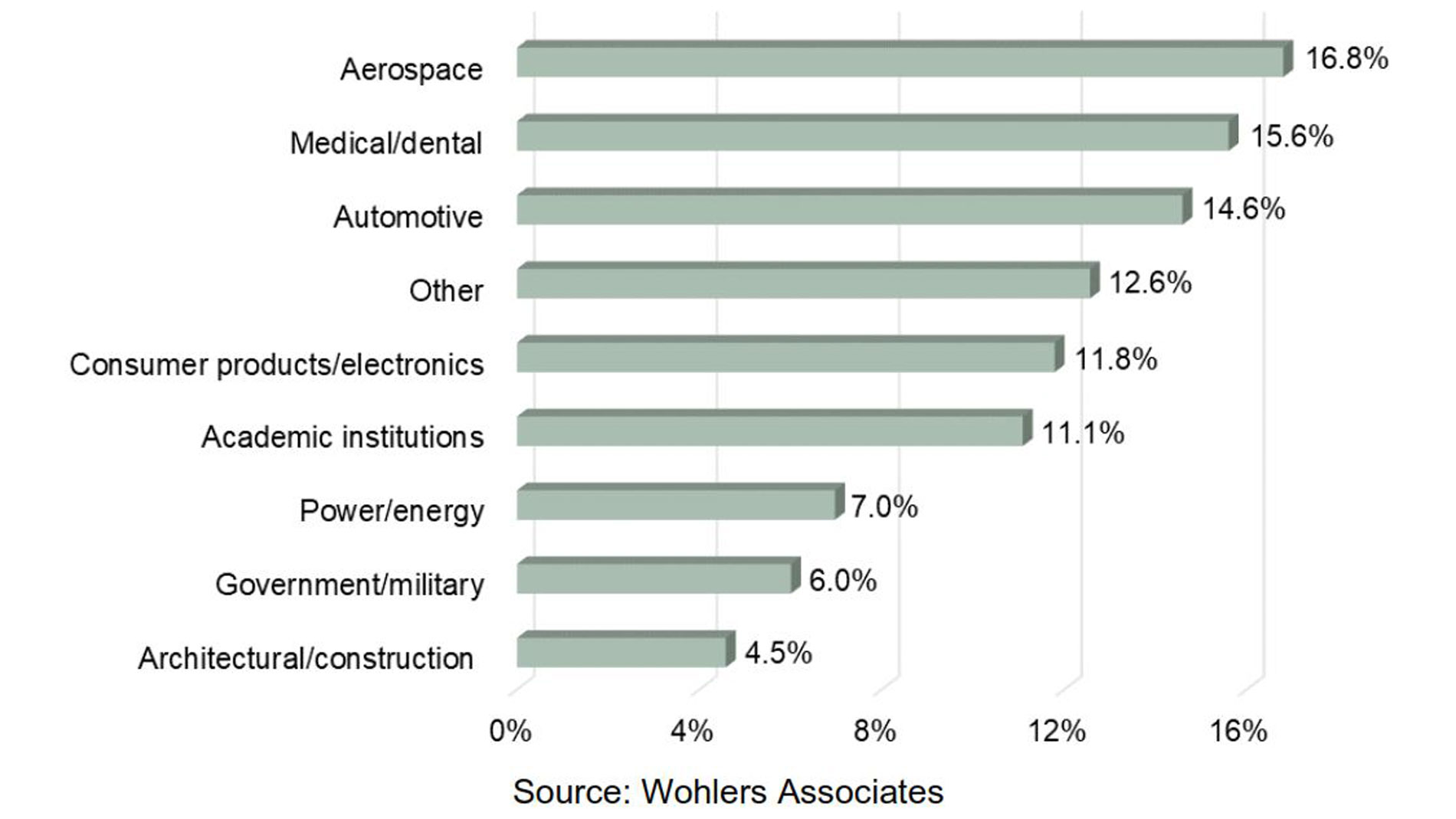

This corresponding to a market share of 15.6 percent, which means the sector trails only the aerospace industry (16.8 percent) in terms of its importance for AM. Coming in third is the automotive industry, with a market share of 14.6 percent.

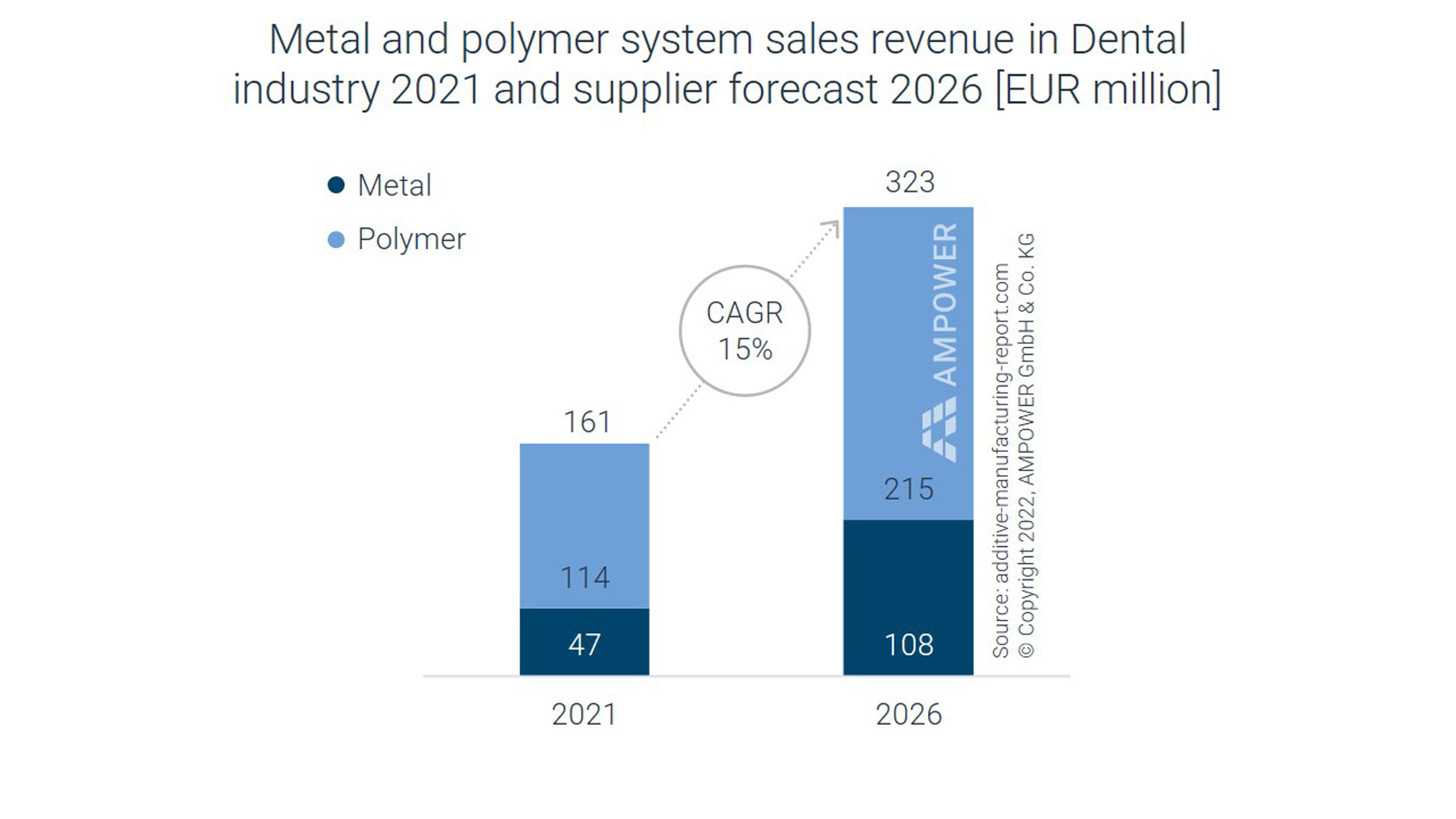

In the future, the many years of strong growth in the additive dental industry are expected to continue – or even accelerate further. The consulting firm Ampower, which specializes in additive manufacturing, expects the dental sector to grow by an average of 15 percent in each of the next five years. This would see the sales of 3D-printed dental systems rise from €161 million (2021) to €323 million by 2026.

As of 2021, plastic systems accounted for the lion’s share of the industry’s business volume (€114 million). Dental systems for metal components generated less than half of that, at around €47 million. Meanwhile, the experts at Ampower are forecasting nearly synchronous growth for the sales of plastic and metal systems in the dental industry. Both areas are expected to more or less double in volume by 2026, with metal applications achieving slightly higher growth rates (see graphic).

More and more dental practices adopting AM innovations

Additive manufacturing has found its way into not only more and more dental practices, but other areas of dentistry, as well – including orthodontics and implantology. 3D-printed drill guides and bite splints, custom-made impression trays, and dental models are a few examples of applications. Using 3D printing to make crowns, bridges, and caps is another established technique.

The way in which additive manufacturing has taken the dental industry by storm also relates to how the technology is able to leverage its full potential in this field. The components required are generally small, complex, and tailored to individual patients. They are also often made of materials like titanium, which is difficult to work with using subtractive methods.

Overview of key AM industries. Quelle: Wohlers Report 2022

Meanwhile, AM has brought considerable improvements to orthodontists and their patients. 3D-printed tooth splints, for example, reduce the cost of treatment while also offering an aesthetic wearers can appreciate. New technical possibilities have emerged in implantology, as well. Bone can be regenerated in a localized manner using 3D-printed titanium cages, which makes it possible to use implants in places where no bone material was previously available.

These developments are giving rise to even more attractive business opportunities for dentists, dental labs, and other users. The certification of processes and products has improved not only manufacturing quality, but the commercial possibilities in the industry, as well.

AM systems sales forecast for the dental industry. Source: Ampower

Knowledge of the entire production process is key

For users, knowledge of the entire production process is key. That includes everything from design, software, and printers to process monitoring, post-processing, and quality control. Formnext offers an excellent overview of the current and future possibilities afforded by AM. On November 15-18, 2022, leading international manufacturers will showcase the latest developments in Frankfurt am Main, Germany. These innovations will include a number of solutions specifically designed for the dental industry, such as small, high-precision 3D printers and corresponding materials for metal dental prostheses

FURTHER INFORMATION:

Tags

- Additive Manufacturing

- Medical technology