PLANSEE SE

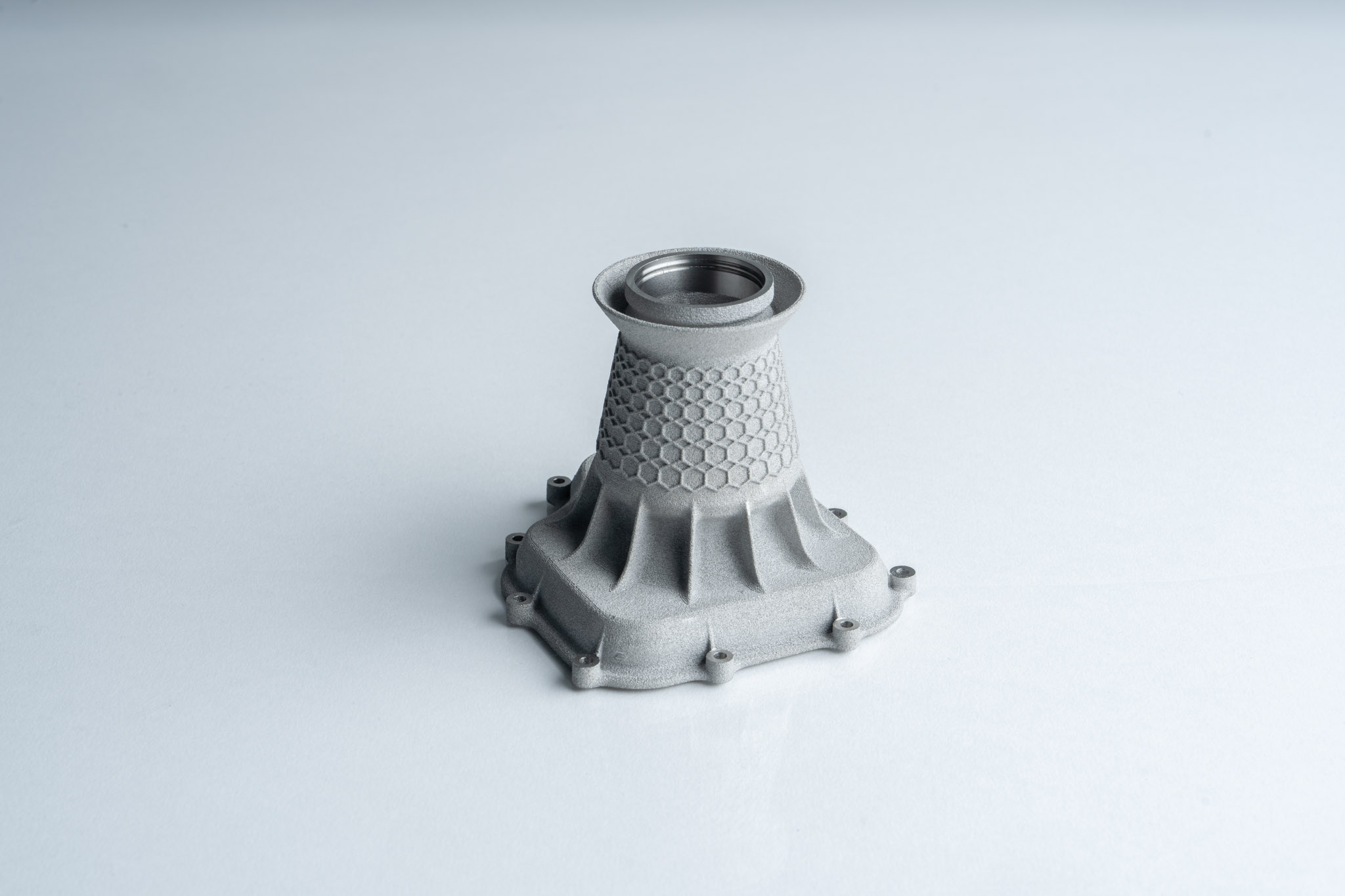

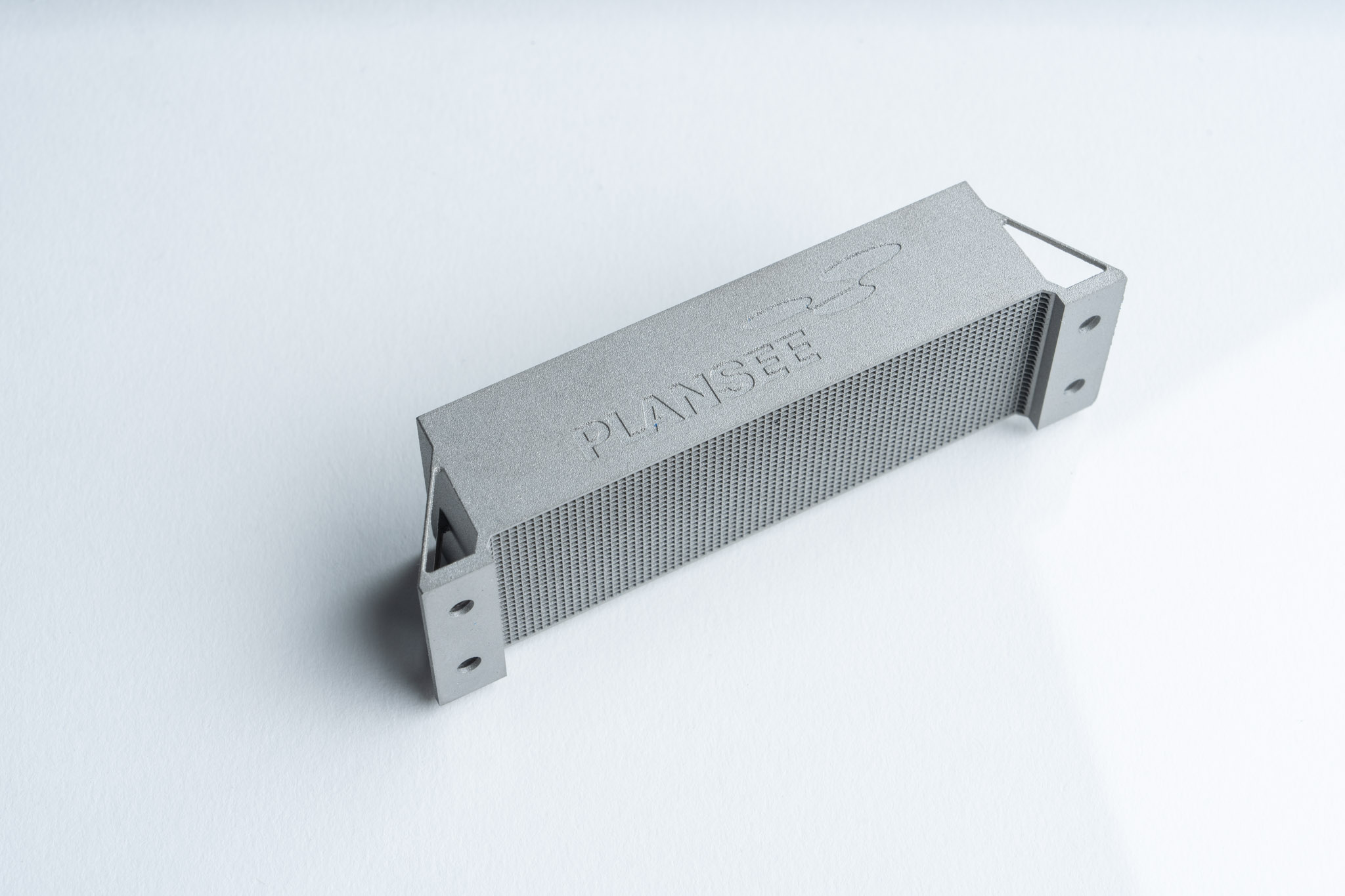

Highlights in 3D printing of refractory metals at Plansee

- Components made from molybdenum, tungsten and tungsten heavy metal

- Parts made from a high-strength Mo alloy

- 100% of the theoretical density for tungsten heavy metal --> Properties as for conventionally manufactured components

Plansee High Performance Materials: Strong metals for strong products

Plansee is the expert in the field of molybdenum, tungsten, tantalum, niobium and chromium products. Refractory metals, alloys and composite materials from Plansee come into use in electronics, coating technology or high-temperature furnaces - wherever traditional materials are stretched beyond their limits. From tiny heat sinks to huge furnace installations: With its strong metals, Plansee delivers products of outstanding quality all around the world.

As a leading enterprise in the field of powder metallurgy, Plansee covers the entire production process in-house – from the ore right to the customer-specific component. To do this, it presses and sinters metal powder and performs a range of deforming operations to manufacture extremely tough, reliable products.

To help its customers boost productivity and encourage technological innovation, Plansee attaches particular importance to research and development. The company works together closely with its customers to develop new materials and product solutions for forward-looking technologies in fields such as clean energy, medical engineering, electronics and mobility.

Plansee is active at 32 locations in 24 countries across the globe. In order to remain the industry’s preferred partner in the field of refractory metals in the future, Plansee continuously invests in the initial training and further development of its 3,000 employees as well as in production capacities and state-of-the-art technology: from powder manufacturing and powder metallurgy processes right up to custom machining and the recycling of raw materials.

To discover more about Additive Manufacturing at Plansee click here: https://www.plansee.com/en/expertise/manufacturing-and-technology/additive-manufacturing.html

CERATIZIT GROUP

With over 100 years of expertise, CERATIZIT is a global leader in hard material technologies. The company is part of the Plansee Group and has grown from pioneering roots to become a key player in the carbide industry.

The group designs and produces high-performance solutions for machining and wear protection, including cutting tools, indexable inserts, and carbide rods. CERATIZIT manages the entire cemented carbide production process, from A to Z, ensuring quality, innovation, and sustainability.

With more than 30 production sites and over 1,000 patents, CERATIZIT serves a wide range of industries such as automotive, aerospace, medical, energy, and many others.

HARD CASES ARE OUR SPECIALITY

We are your ideal partner when it comes to high-quality hard materials for production processes, tool manufacturing and wear protection.

From standard products to tailor-made solutions, from massive components to minute parts, from the blank to the fully finished product – a product that meets the highest standards of precision, surface treatment, and user-friendly assembly – our carbide solutions ensure improved efficiency and outstanding total cost of ownership.

MATERIALISING SOLUTIONS TOGETHER

We have developed additive manufacturing technologies for our tested cemented carbide grades which are ready to use for your product.

Our experts will be happy to assist you in the following areas:

- Simulation and modelling

- Design adaptation to additive manufacturing

- Material selection

We will help you choose the right technology for your product.

Our product groups

- Design and engineering

- Part manufacturing

- Industrial tool and die making

To discover more about Additive Manufacturing: CERATIZIT | Additive Manufacturing