Find instead of search – our market directory offers a comprehensive overview of providers, suppliers, manufacturers and the latest solutions and products for Additive Manufacturing with detailed profiles of all Formnext exhibitors.

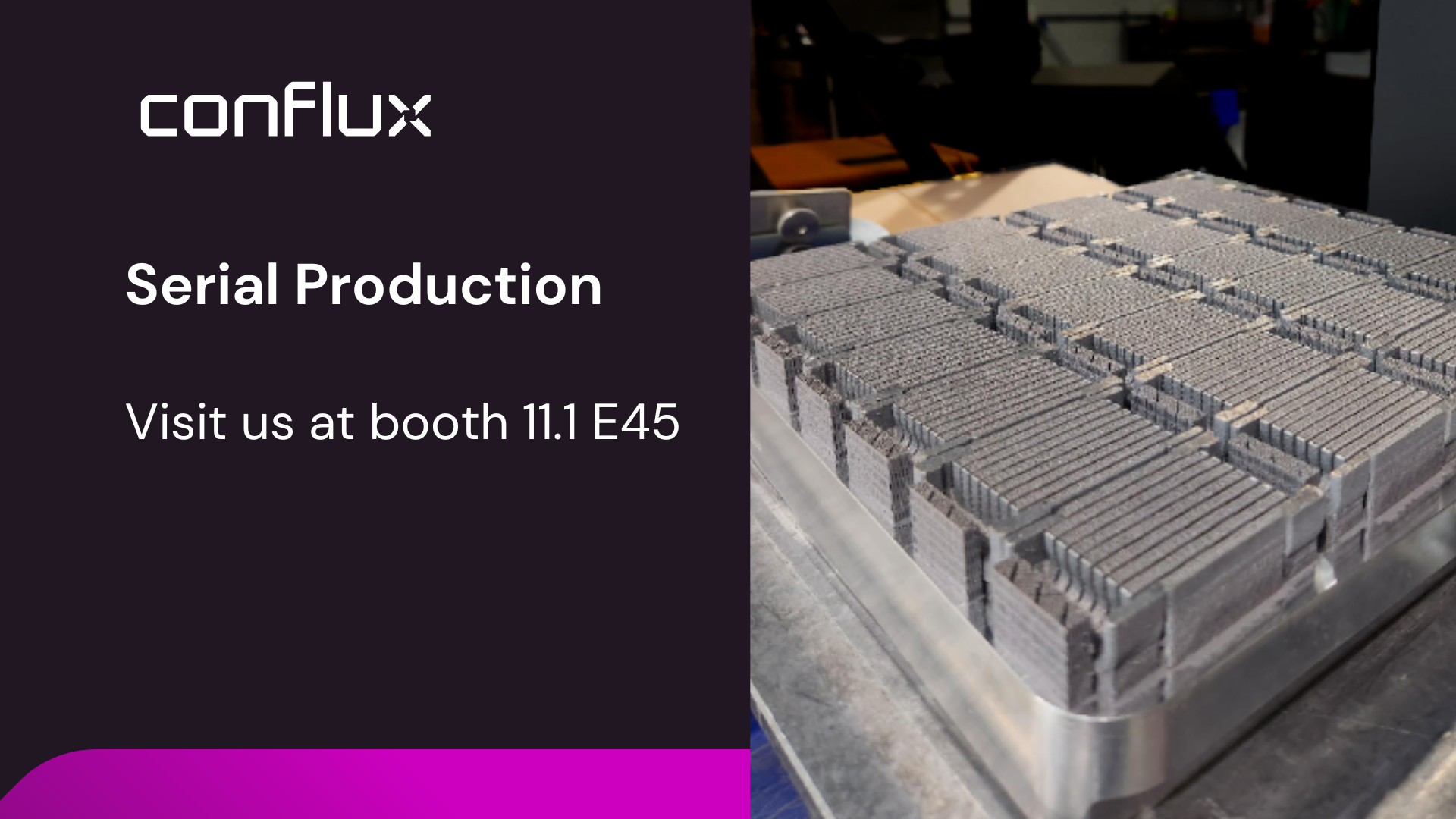

Cold plates

Description

Boost the performance of your cold plates for eVTOL with ultra-high performance heat transfer technology from Conflux Technology

Conflux cold plates are designed to improve the thermal management of batteries and meet the needs of the advanced air mobility sector; crucial for the performance and safety of eVTOLs. With the increasing demand for batteries with high energy density, long cycle life, and fast rechargeability, our cold plates provide an effective solution for cooling the batteries during system running and ultra-fast charging.

Our additive manufactured cold plates reduce the temperature of the heat source by pushing cooled air or fluids to the heat source. This technology improves the specific energy and specific power of batteries, which are critical for the performance of eVTOLs.

With the increasing demand for eVTOLs and the emergence of new battery technologies such as solid-state batteries, sodium-ion batteries, and fuel cell technology, our cold plates provide a reliable and efficient solution for thermal management in the eVTOL and air mobility sector.

Conflux cold plate technology enhances the performance of cold plates for eVTOL through:

Achieving complex geometries: Additive manufacturing techniques can achieve cold plates with complex 3D geometries that were previously impossible to manufacture. This allows us to maximize the cooling capacity within the available space, achieving efficient heat exchange in small areas.

Reducing weight, volume, and pressure drop: Traditional manufacturing methods for cold plates are limited in terms of design flexibility, which can lead to bulky and heavy components. Our heat exchangers can reduce the weight and volume of your cold plates while also reducing pressure drop, which is critical for efficient cooling.

Rapid prototyping and testing: We rapidly configure design, prototyping and testing of cold plates, allowing our engineers to quickly iterate designs and fine-tune performance. This can significantly reduce the time and cost of developing cold plates for eVTOL.

Partner with the experts who specialise in additive manufacturing heat transfer

Visit us at Formnext Frankfurt, booth 1.11 E45 and see our cutting-edge cold plates and vapor chambers for yourself.

Contact peter.rosker@confluxtechnology.com to book a meeting.

Address

Conflux Technology

Building NP 2.110

Pigdons Road 75

3216 Waurn Ponds

Australien

Telephone+61 408 516 900

Discover more from us