Find instead of search – our market directory offers a comprehensive overview of providers, suppliers, manufacturers and the latest solutions and products for Additive Manufacturing with detailed profiles of all Formnext exhibitors.

Heat Exchangers for Aerospace Applications

Description

Ultra-high performance and efficient heat transfer technology

We use additive manufacturing to make high performance heat exchangers for all industries; delivering reliable products that are lighter and more efficient. We take your thermal performance needs and produce game-changing outcomes with our unique technology.

As recognised experts in the heat transfer application space, we leverage the design freedoms enabled by 3d printing to create cutting-edge heat transfer solutions for customers across the globe.

3D Printed Heat Exchangers for Industrial Machines

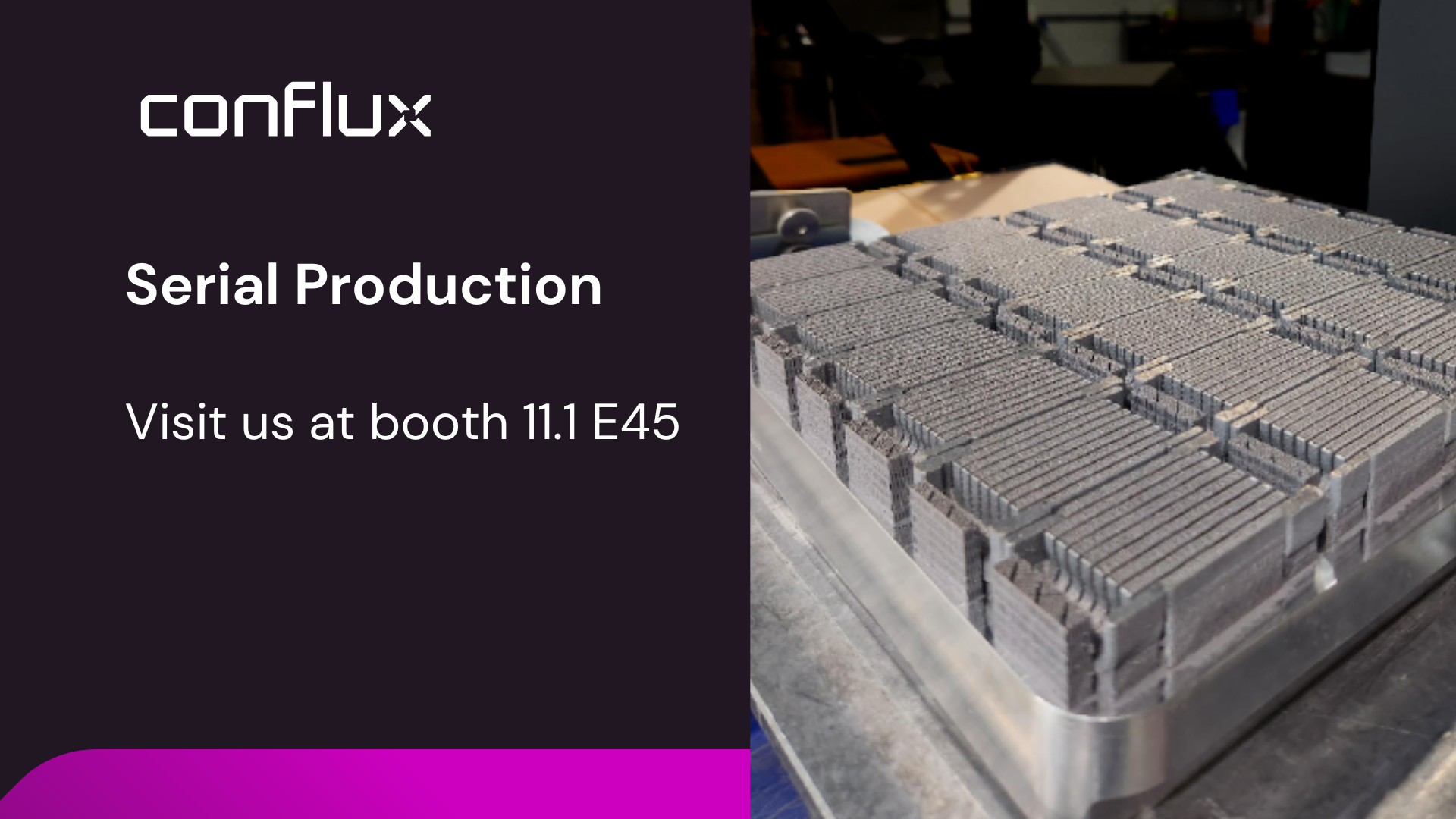

Conflux Technology’s cutting-edge proprietary techniques deliver the most advanced 3d printed heat exchangers for use in industrial machine applications.

The advantages offered by additive manufacturing for Industrial applications are numerous:

- Smaller and more efficient heat exchangers: Reduce the size, weight and efficiency of your heat exchange and take advantage of design freedoms enabled by AM.

- Improved thermal conductivity: Additive manufacturing can create heat exchangers with complex internal geometries that can improve heat transfer and thermal conductivity.

- Customization and creation of special shapes: We can create heat exchangers in a range of shapes that have an advantage over traditional manufacturing methods.

- Rapidly configured: Each of our patented heat exchanger core designs is rapidly configured to your specific requirements and boundary conditions.

- Serial Production: Proven, reliable serial production partners. Volume production orders deliver cost and production efficiencies.

-Single-piece manufacturing / monolithic parts: Reducing multiple parts into a single piece allows you to avoid assemblies with welded seams, and multiple connections, and reduce manufacturing steps. All save time and weight.

This year at Formnext we will be showcasing a unique industrial machine heat exchanger. Come and see for yourself at our booth #1.11 E45.

Book a meeting today with peter.rosker@confluxtechnology.com our EMEA Business Development Manager.

Address

Conflux Technology

Building NP 2.110

Pigdons Road 75

3216 Waurn Ponds

Australien

Telephone+61 408 516 900

Discover more from us