See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

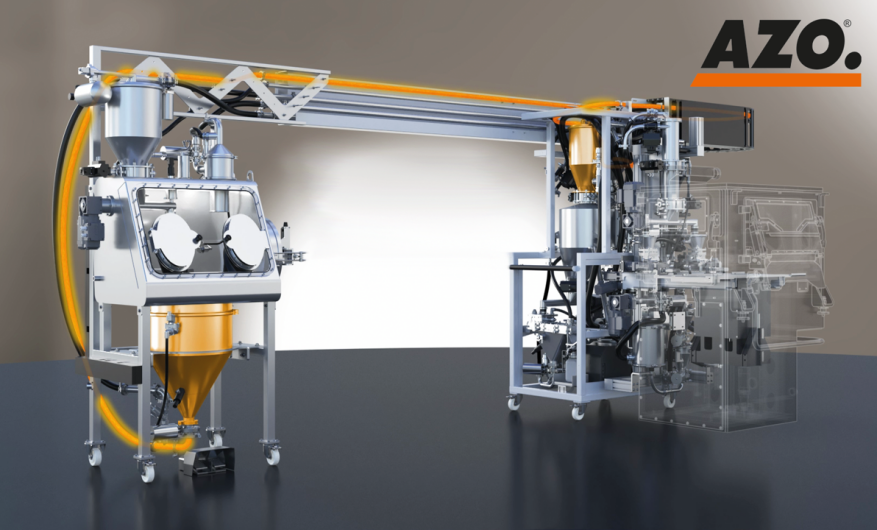

Automated handling of metal powders in a closed circuit under an inert gas atmosphere

Automated handling of metal powders in a closed circuit under an inert gas atmosphere

Description

Whether individual solutions or entire printing factories: With AZO, you have the right partner at your side when it comes to efficient and economical automated raw material conveying, processing and recycling.

Module GLOVEBOX - Safe product delivery

The feed bins are brought in and taken out via the side-mounted hatch

Before the process is released, the GloveBox and the other modules of the system are fully inerted.

The metal powder is fed from the storage hopper to the screeing module with a vacuum conveyor.

The re-filling of the feed bins for emptying the entire system is realized via the receiver above and a dosing screw installed in the GloveBox.

Module SCREENING - Preparation of the metal powder

The receiver with a central filter is used to collect virgin material, overflow material or unpacking material

The storage hopper is equipped with a weighing frame for filling level monitioring

The AZO dosing screw ensures controlled dosing into the screener

The ultrasonic screener is adjustable for different metal powders

The sieved metal powder is transported to the printer module with a gentle vacuum conveying system

Module PRINTING - Reliable printer feeding

Feeding of the dosing devices in the printer with a dosing screw

One or more inlets / feed points can be fed

Buffer container is installed below at the bottom of the printer module for collecting the overflow material

The overflow metal powder is automatically returned with the vacuum conveying system to the screening module for recycling

Module PRINTING - Unpacking of the components

The job box is unpacked with a suction lance with simultaneous inert gas feeding into the printer chamber

The vacuum conveying brings back the unpacking material to the screening module or to the GloveBox for emptying of the system