See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

Fascinating applications

Description

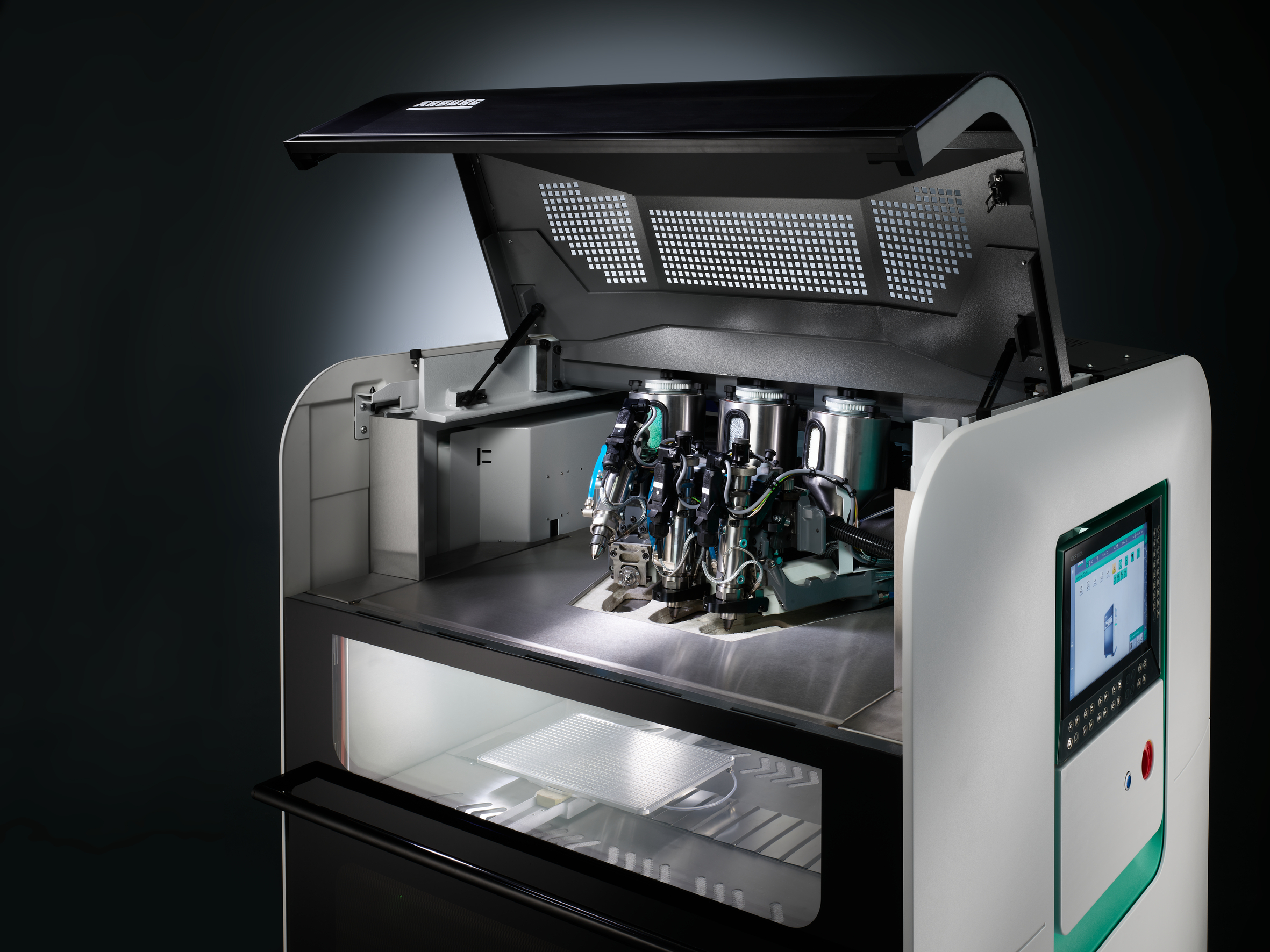

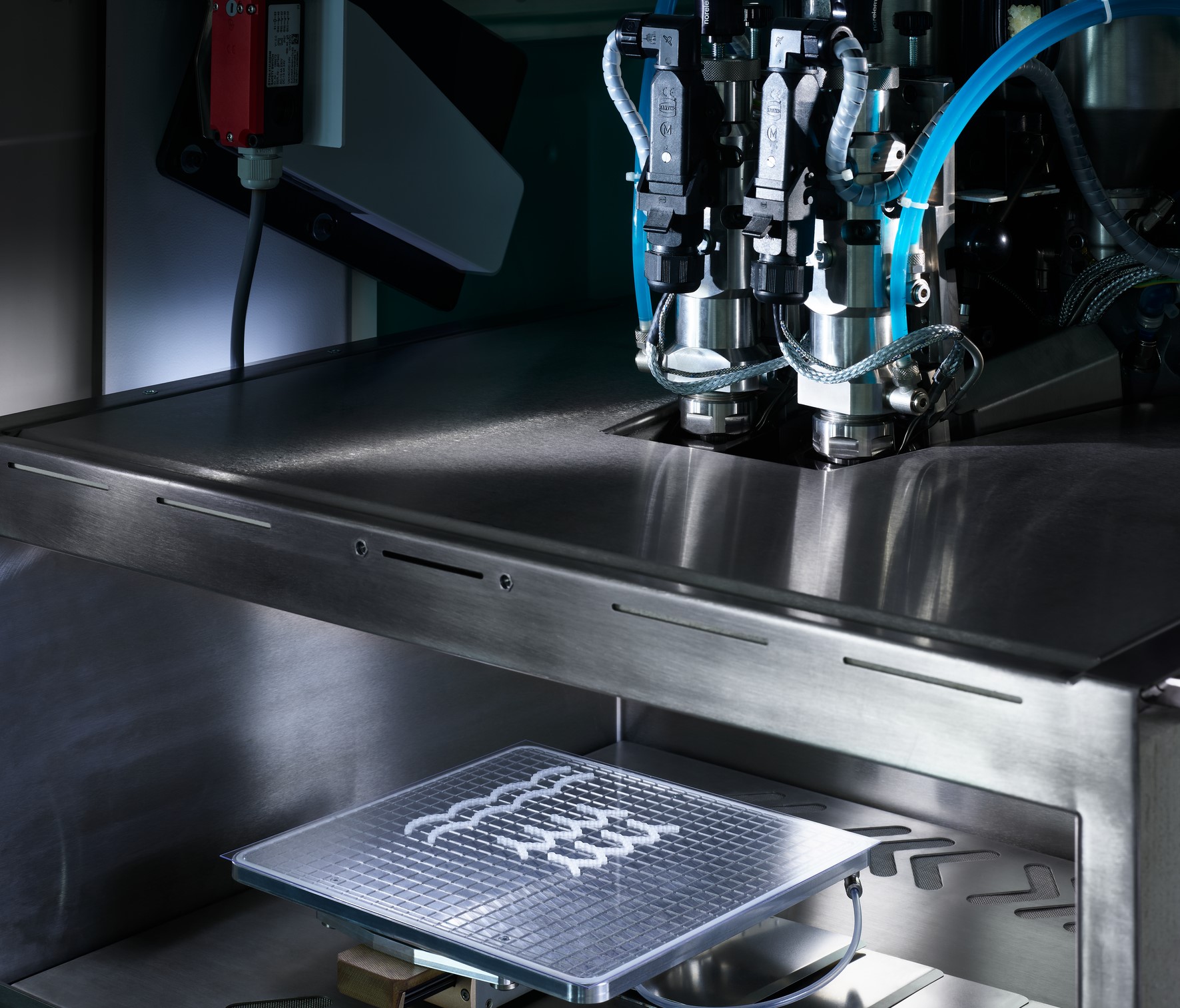

One application example of how 3D printing and automated injection moulding processes can be optimally combined can be seen in the production of plant pots. An electric ALLROUNDER 720 A injection moulding machine with a 4-cavity mould produces the thin-walled pots from recyclate. To gently remove the pots from the mould, Osko uses a special packaging automation system with grippers that are precisely adapted to the product. These grippers can be quickly 3D-printed on demand. The sturdy black middle section, made of fibre-reinforced plastic filament and produced with a TiQ printer, is two to three times lighter and significantly cheaper than an aluminium component. The four white gripping rings in a hard/soft combination were produced by a freeformer using the APF process. To remove the plant pots, the soft gripper part is “inflated” with compressed air, allowing the injection-moulded part to be fixed and handled gently.

A freeformer customer in the medical technology sector has developed a novel application that can replace or at least delay complex knee operations with metal implants. The alternative is called "iKnee": using the patented Resilient Arthroplasty Device (RAD) technology, a patient-specific implant made from biocompatible polycarbonate is inserted into the knee as a cartilage replacement using a minimally invasive procedure.

Address

ARBURG GmbH + Co KG

Arthur-Hehl-Str.

72290 Loßburg

Deutschland

Telephone+49 7446 330

Fax+49 7446 333365

Discover more from us