Text and Pictures: VoxelMatters, 09 October 2024

A look at the importance of AM service providers in the global additive industry, with current standings of the top companies by revenue in Polymers, Metal and Ceramics

AM Service providers are a key segment to analyze as they are both part of the “core AM industry”, together with AM hardware and AM materials, and they can also be considered as a vertical adoption segment, like Aerospace, Automotive, etc. As a part of the core AM industry, AM service providers serve all different verticals by providing printed parts. Assessing the unit numbers, average size and average cost of these parts enables us to assign a value to the parts that vertical AM adopters produce internally.

The emergence of 3D printing services

The rise of 3D printing services began with the adoption of rapid prototyping in the early days of AM. This approach allowed companies to quickly create physical models of their designs, significantly cutting down the time and cost of traditional prototyping methods. Firms could send their digital designs to a service provider, who would produce the prototype using cutting-edge 3D printing technologies such as stereolithography (SLA) and selective laser sintering (SLS). Once the prototype was ready, it would be sent back to the client for evaluation. Key players in this early market included companies like Materialise and Proto Labs, which were among the first to offer rapid prototyping services at scale, setting the stage for the modern AM service industry.

As AM technology matured, so did the capabilities of 3D printing service providers. What once was limited to rapid prototyping has expanded into producing final parts and even complete, end-use products. The evolution from prototyping to production marked a significant shift in the AM industry. Companies began turning to 3D printing services not just for one-off prototypes but for small-batch and mass production of customized components. The arrival of this era gave rise to the AM factories—facilities equipped with large fleets of industrial 3D printers capable of handling large production volumes. These modern service providers pushed the limits of AM, offering both businesses and individual consumers the ability to create complex, high-quality parts on demand.

From rapid prototyping to AM factories

The advent of AM factories represented a significant leap from traditional 3D printing services. Unlike earlier service models focused on single or low-volume prints, AM factories are equipped with vast arrays of printers, advanced automation technologies, and digital workflows. They can produce parts at a larger scale, often with quicker turnaround times and reduced costs. What sets AM factories apart is their ability to offer full-scale production capabilities, from customized small-batch runs to mass production of high-quality parts. These facilities represent a new breed of 3D printing service providers, focused not just on offering prototypes but on providing businesses with full production capabilities through AM technology.

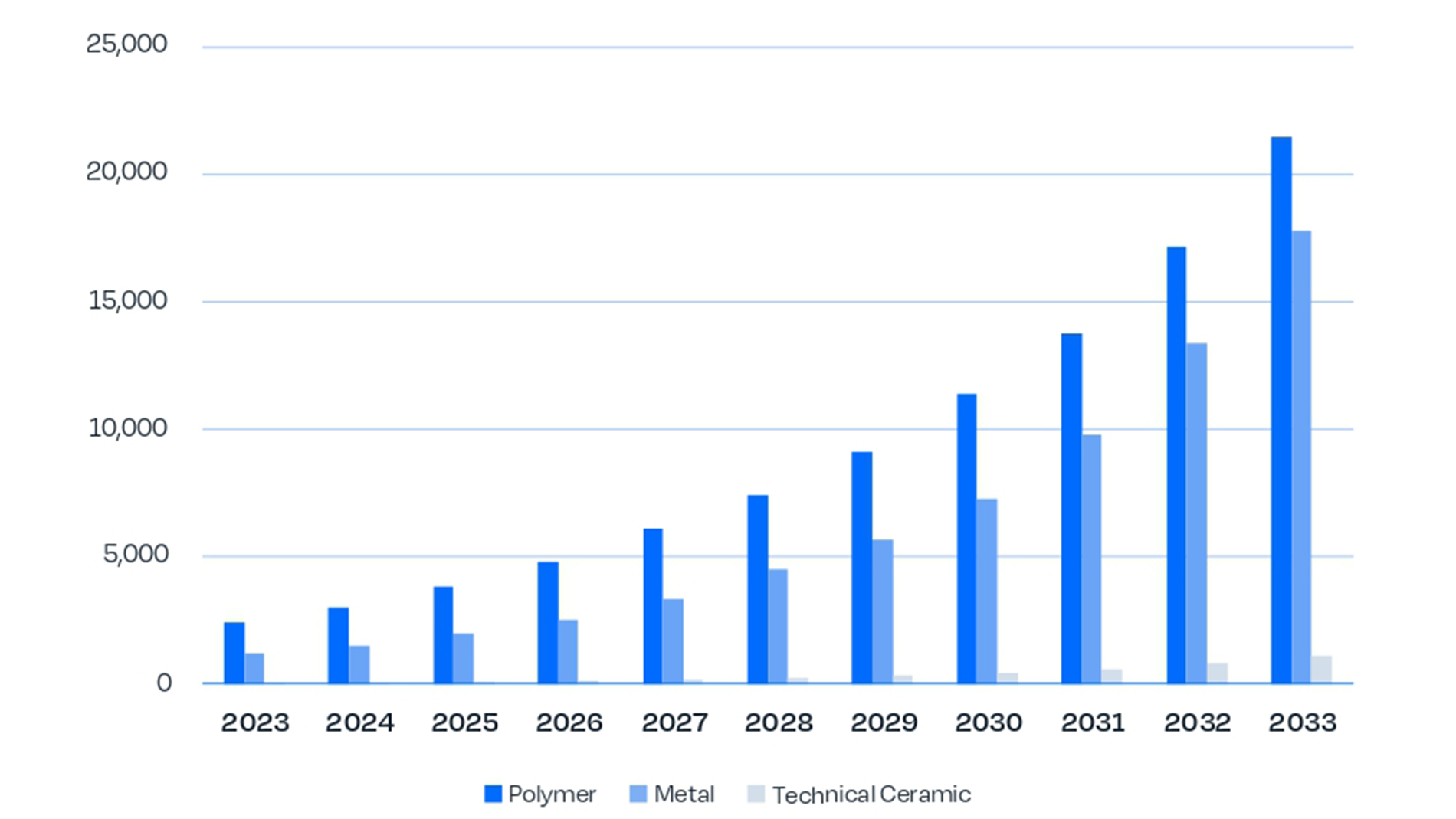

AM services overall revenue (USD M) 2023-2033. Source: VoxelMatters Research

Rapid prototyping remains one of the most significant contributions of 3D printing services to product development. Traditionally, creating prototypes involved extensive time and resources, particularly when working with complex designs. With the advent of 3D printing, rapid prototyping revolutionized this process by allowing engineers to quickly test designs, make iterations, and optimize final products. Rapid prototyping typically employs technologies like SLA, SLS, and fused deposition modeling (FDM), each offering different benefits in terms of material properties, accuracy, and speed. This allowed industries ranging from aerospace to consumer goods to innovate faster and bring new products to market with reduced risk and cost.

Companies like Materialise and Proto Labs were pioneers in offering rapid prototyping services. They provided clients with access to cutting-edge 3D printing technologies without requiring them to invest in expensive equipment. Materialise, for example, became known for its innovations in software and design solutions, while Proto Labs established itself as a leader in rapid manufacturing through its investment in digital factories. These companies set the standard for the broader AM service industry, establishing 3D printing as a viable alternative to traditional prototyping and manufacturing methods.

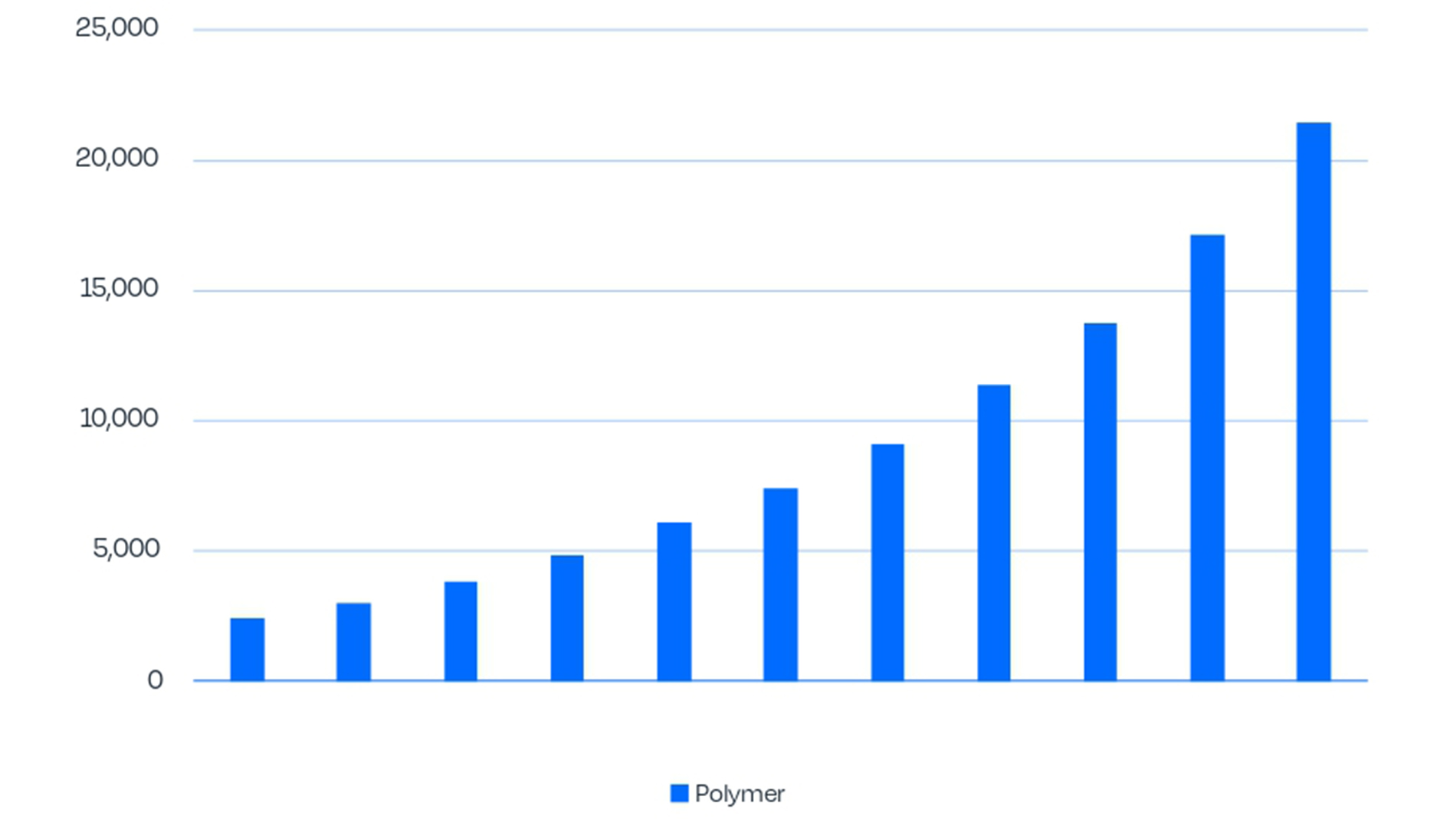

AM services polymer revenue (USD M) 2023-2033. Source: VoxelMatters Research

The concept of AM factories took the evolution of 3D printing services to the next level. These service providers go beyond just prototyping and low-volume production. Equipped with fleets of industrial 3D printers and highly automated systems, AM factories have the capability to produce high-quality, customized parts at scale. This shift is especially important for industries such as automotive, aerospace, and healthcare, where precision, customization, and short lead times are critical. Unlike their predecessors, AM factories can handle large production runs while maintaining the flexibility to produce small-batch orders, making them a go-to resource for businesses looking to take advantage of the benefits of AM without investing in their own equipment.

Pioneering AM service players in the global market

Some of the most well-known AM factories include companies like Stratasys Direct, OECHSLER, ADDMAN, BLT, Falcontech, and BEAMIT. These companies have invested heavily in expanding their production capabilities, offering a wide range of services from rapid prototyping to large-scale manufacturing. Their focus on automation and digital workflows enables them to meet the growing demand for AM parts across industries, particularly in aerospace and automotive manufacturing, where complex designs and high-performance materials are required.

The rapid growth of AM has also led to the development of global networks of 3D printing service providers. Companies such as Xometry, Fictiv, and Makerverse have built platforms that connect businesses with a global network of AM service providers. These networks allow for distributed manufacturing, which enables companies to produce parts closer to where they are needed. This is particularly beneficial for industries like healthcare and aerospace, where the ability to rapidly produce and deliver parts on demand can significantly reduce downtime and logistics costs.

Distributed manufacturing is one of the most significant benefits of working with global AM networks. Rather than centralizing production in one location, parts can be produced closer to where they are needed, reducing shipping costs and lead times. This model is made possible by the widespread availability of 3D printing services across the globe, allowing businesses to take advantage of local manufacturing resources. Distributed manufacturing also allows for greater customization, as parts can be tailored to specific needs and produced on demand.

Automation and digital workflows in AM

As the scale and complexity of AM services have grown, so too has the integration of automation and digital workflows. Automation technologies such as advanced robotics and sophisticated software platforms are now commonplace in AM factories, helping to streamline the entire production process from design to final part. This not only improves efficiency but also reduces the potential for human error, resulting in higher-quality parts. Furthermore, digital workflows enable seamless integration between design, production, and quality control, allowing for faster turnaround times and greater scalability.

The introduction of advanced robotics, coupled with powerful AM software, has revolutionized production capabilities in AM factories. Robots are now used for everything from preparing prints to post-processing, reducing the need for human intervention and increasing the speed of production. Additionally, advancements in machine learning and artificial intelligence are improving the way designs are optimized for 3D printing, further enhancing the efficiency and accuracy of the process.

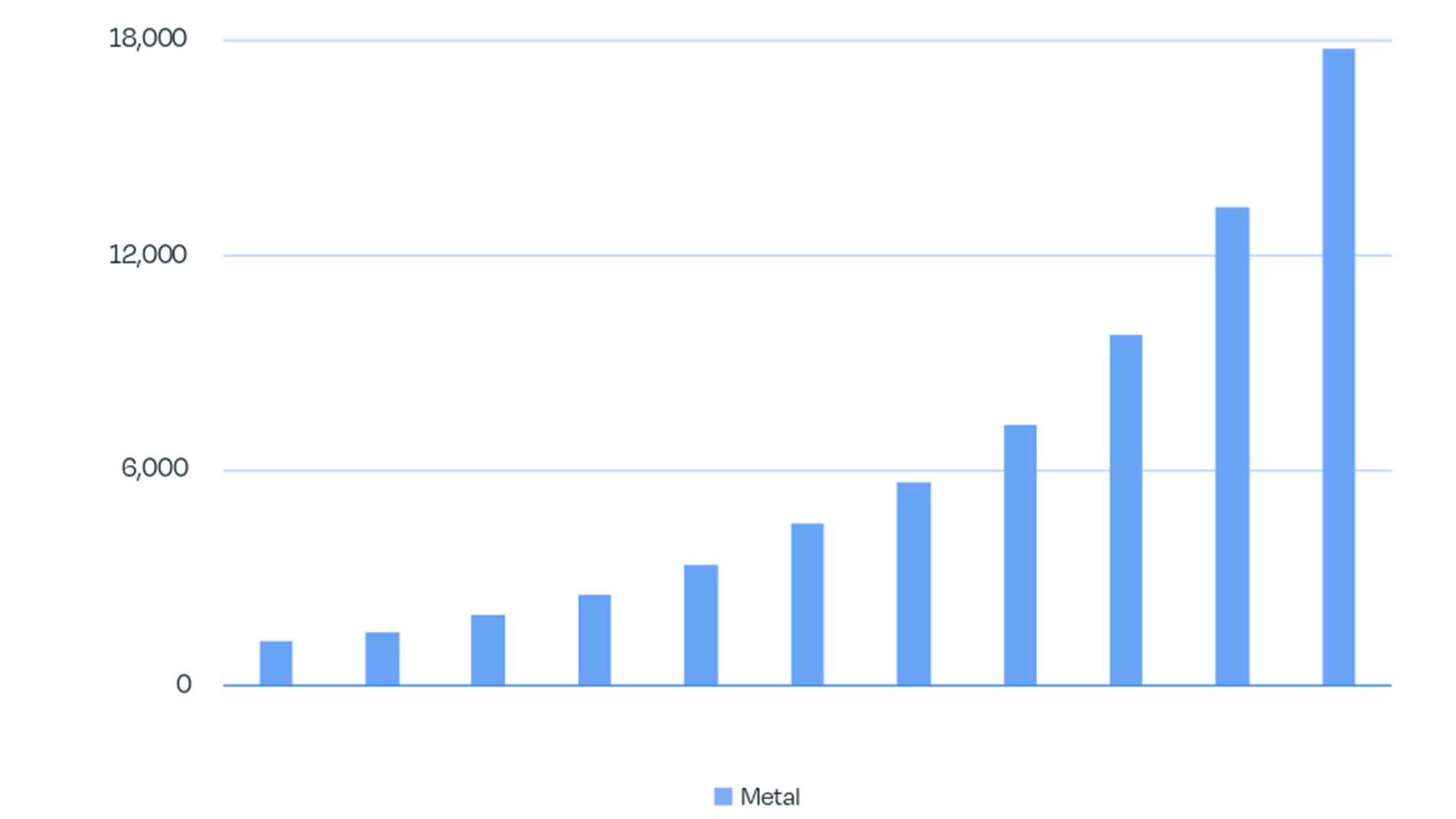

AM services metal revenue (USD M) 2023-2033. Source: VoxelMatters Research

One of the most significant benefits of partnering with 3D printing service providers is the ability to leverage on-demand production. On-demand manufacturing allows businesses to produce parts as needed without investing in large inventories or expensive equipment. This is particularly valuable for small and medium-sized enterprises (SMEs) that may not have the resources to build their own AM capabilities in-house. By producing only what is required when it’s needed, companies can reduce waste, lower costs, and maintain flexibility in their operations.

Main types of AM service providers

Application-agnostic AM service providers are those that serve a broad range of industries and applications without focusing on a specific niche. These providers often offer a variety of 3D printing technologies and materials, making them versatile and capable of handling diverse client needs. Companies like Protolabs, Sculpteo (now Forward AM), and Xometry fall into this category, offering services across industries such as healthcare, automotive, consumer goods, and aerospace.

On the other hand, application-specific AM service providers focus on a particular industry or application, providing deep expertise in that area. For instance, Aidro specializes in industrial hydraulic and fluid flow components, while Sintavia focuses on aerospace, producing lightweight and high-strength components for aircraft. These providers often work closely with their clients to develop customized solutions tailored to specific industry requirements, such as design optimization, material selection, and post-processing techniques.

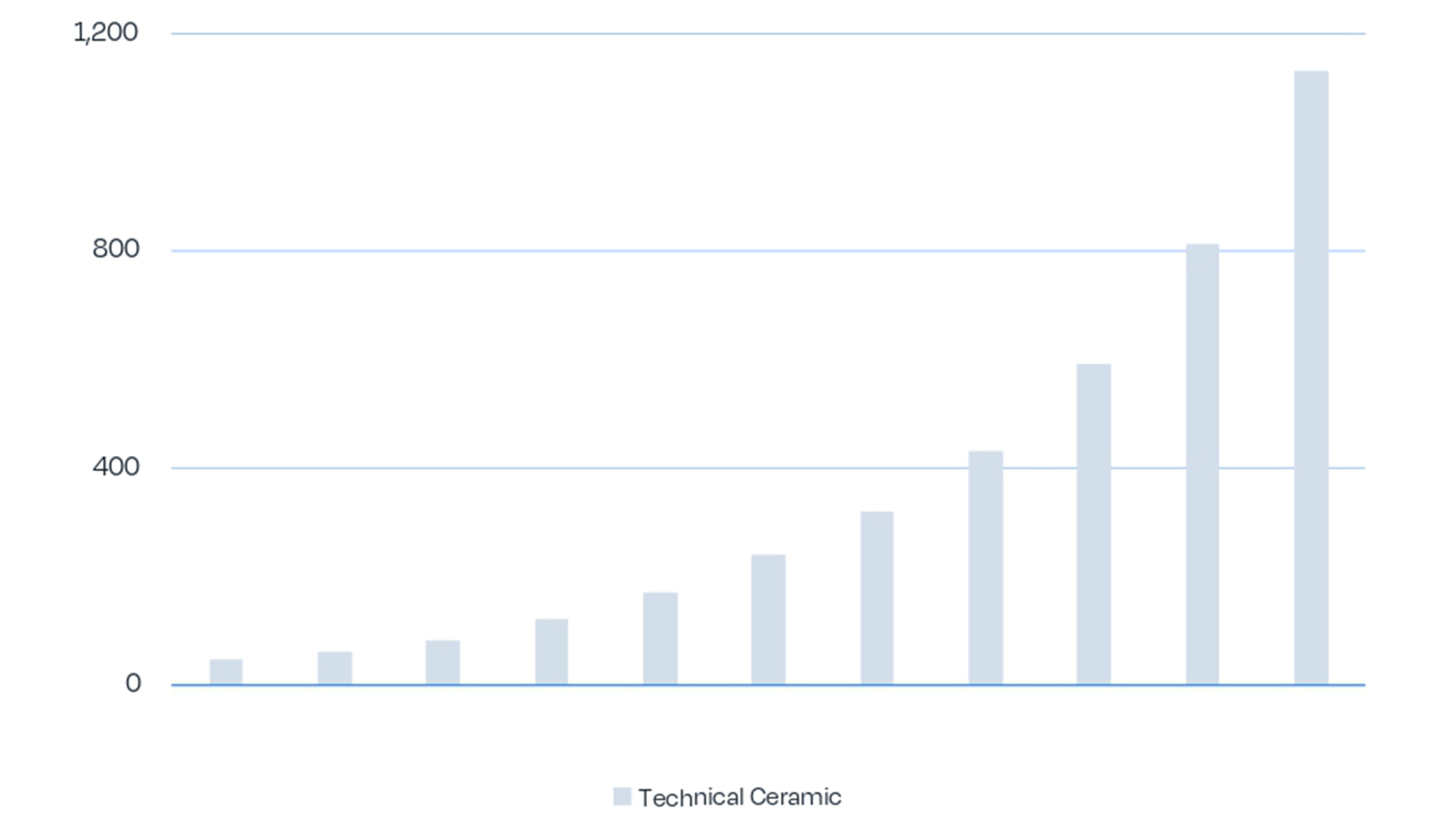

AM services technical ceramic revenue (USD M) 2023-2033. Source: VoxelMatters Research

One of the major advantages of working with AM service providers is access to their extensive industry knowledge and technical expertise. These companies have years of experience in various aspects of AM technology, from material science to design optimization. By partnering with AM service providers, businesses can gain a deeper understanding of how to effectively implement 3D printing in their operations. This collaboration often leads to more innovative solutions and helps companies stay competitive in fast-moving industries.

The VoxelMatters Directory serves as a comprehensive resource for companies seeking 3D printing service providers. Listing over 1,850 AM service bureaus, the directory is categorized into key subcategories such as AM Factories, Global AM Service Networks, Application-Agnostic Providers, and Application-Specific Providers. Each listing provides detailed information about the services offered, the technologies used, and the industries served, making it easier for businesses to find the right partner for their needs.

Key subcategories in VoxelMatters Directory

The VoxelMatters Directory categorizes AM service providers into several key subcategories, each representing a distinct service specialization. These include:

- AM Factories: Large-scale production facilities for customized parts.

- Global AM Service Networks: Distributed manufacturing networks that offer local production on a global scale.

- Application-Agnostic Providers: Service providers offering a broad range of AM solutions across industries.

- Application-Specific Providers: Specialized firms focusing on particular industries or applications.

This categorization ensures that companies can quickly identify the best AM service provider for their specific needs.

The future of AM service providers

As AM technologies continue to evolve, several key trends will shape the future of 3D printing service providers. Distributed manufacturing is expected to become even more widespread, with more companies adopting AM for local production. Automation will continue to play a critical role, streamlining production and improving efficiency. Additionally, advancements in materials science and new AM technologies will likely open up new opportunities for mass production through 3D printing. The role of service providers will remain essential as they help businesses navigate these advancements and continue to push the boundaries of what is possible with AM.

The evolution of 3D printing service providers from rapid prototyping specialists to full-scale AM factories has been a driving force in the growth of the AM industry. These providers have enabled businesses of all sizes to adopt and benefit from AM technologies without the need for large capital investments. As the industry continues to evolve, 3D printing service providers will remain at the forefront, helping to drive innovation, efficiency, and new applications across a range of industries. The future holds exciting possibilities, with trends such as distributed manufacturing, automation, and material innovation set to further expand the role of these providers in global production.

The following charts leverage preliminary data* from VoxelMatters' core AM database to assess the top 10 largest companies from each segment—polymers, metals, and ceramics—by yearly AM-specific revenues.

*Note that the data is still being elaborated for the upcoming versions of VoxelMatters Polymer, Metal and Ceramic AM market studies. Final versions of the reports may differ slightly

Top 10 Polymer AM Services

1. Materialise

One of the most established names in AM services, Materialise is known for its deep expertise in polymers (but now also provides metal AM). The company’s focus on healthcare and industrial applications gives it a strong foothold in both specialized and high-volume markets. Materialise also provides leading AM software solutions, further solidifying its position in the industry.

2. Stratasys Direct

A subsidiary of Stratasys, Stratasys Direct has been a significant player in polymer AM services for many years (it used to be called Red Eye). Leveraging the parent company’s advanced hardware, as well as other technologies including SLS, they cater to multiple verticals, including automotive and aerospace, with a focus on high-quality parts production.

3. Quickparts

Quickparts (a “spinout” from 3D Systems) offers rapid prototyping services and small-batch production with a strong emphasis on speed and quality. They are known for their diverse material offerings, and their service model caters well to both startups and large enterprises.

4. Protolabs

Protolabs excels in offering fast-turnaround parts through their automated quoting system. With facilities in the US and in Europe, they provide AM services in polymers (and metals), offering a wide range of prototyping and production solutions. They also own the Hubs network.

5. WeNext

A Chinese-based service provider, WeNext has gained traction by catering to the rapid growth in Asia’s demand for AM services, particularly for consumer goods and small industrial parts.

6. FIT AG

FIT AG is recognized for its expertise in additive manufacturing solutions for industrial applications. Their extensive experience in AM and focus on high-performance polymers makes them a key player in European markets.

7. Unionfab

As a sister company of SLA hardware company Uniontech, Unionfab is another China-based service provider making waves in the AM space. They offer a variety of polymer-based AM solutions across multiple verticals, with a strong emphasis on precision and scalability.

8. Fathom

Fathom is one of the largest on-demand digital manufacturing platforms in North America, serving low- to mid-volume manufacturing needs. With nearly 450,000 square feet of manufacturing capacity across 12 facilities, Fathom blends in-house capabilities across plastic and metal AM and other technologies, serving clients in the defense, aerospace, medical, automotive and IOT sectors.

9. JLC3DP

JLC3DP has a team of over 200 professionals and a cutting-edge 13,000 square meter production workshop, we specialize in top-tier 3D printing and CNC machining services. The rising Chinese-German company strives to deliver quality at competitive prices, for clients to receive the utmost value without compromise.

10. Prototal

A leading provider of polymer AM services in Scandinavia (with branches in the UK and Italy), Prototal specializes in producing functional parts for a range of industries, including medical devices, industrial applications, and consumer products.

Top 10 Metal AM Services

1. Bright Laser Technologies (BLT)

Based in China, BLT has grown to become the leading metal AM service provider globally, focusing heavily on aerospace and medical applications, using its own metal L-PBF technology. Their capabilities in large-format metal parts production give them an edge in industries with high-performance requirements.

2. Sintavia

An American leader in metal AM, Sintavia focuses primarily on the aerospace and defense sectors, providing highly specialized, certified metal parts that meet stringent industry standards.

3. Falcontech

Falcontech is a key player in China's metal AM services, particularly for aerospace and automotive industries. The company partners with Farsoon to power it Super AM Factory, known for producing high-quality, lightweight metal parts. The company is now expanding its presence globally.

4. Nano Dimension (Desktop Metal/ExOne)

Nano Dimension has become a significant player in metal AM services after acquiring Adamtec, Desktop Metal and ExOne. With its diverse metal AM offerings, including both metal binder jetting and bound metal slurry technologies, it serves a wide array of industries, from automotive to consumer electronics.

5. ADDMAN

ADDMAN focuses on producing precision metal parts for demanding industries like aerospace and defense. Their rapid expansion through acquisitions and investment in cutting-edge technologies make them one of the top metal AM service providers in the U.S.

6. Quickparts

Along with their strong polymer offerings, Quickparts also provides metal AM services, making them a versatile provider across the entire AM spectrum. Their global presence gives them access to multiple industrial verticals.

7. FIT AG

FIT AG’s metal AM services complement their polymer offerings, with a focus on high-performance metal parts for aerospace and automotive sectors. Their expertise in engineering and manufacturing solutions is widely recognized across Europe.

8. Toolcraft

A Germany-based AM service provider (via the AMbitious program), Toolcraft is known for its expertise in precision metal parts for industrial sectors like aerospace, automotive, and energy. Their quality control and high-level certification processes are key differentiators.

9. Oerlikon

Oerlikon is a global leader in surface solutions and additive manufacturing, offering extensive metal AM services. Their strong focus on industrial applications like aerospace, automotive, and energy ensures they remain a top player.

10. Protolabs

Protolabs’ metal AM services focus particularly on prototypes and low-volume production. They provide a fast, scalable solution for industries needing rapid design iterations.

Top 10 Ceramic AM Services

1. Nano Dimension (Formatec, Desktop Metal, ExOne)

Nano Dimension, with its subsidiaries Formatec and ExOne, is now the leading service provider in the ceramics AM market. They specialize in producing high-performance ceramic parts for industries like healthcare, electronics, and aerospace.

2. Steinbach

A major user of Lithoz technology, Steinbach is a well-established German provider of technical ceramic solutions, offering AM services to sectors requiring high-precision and durability in extreme conditions, such as aerospace and energy.

3. Schunk Carbon Technology

Schunk is a global leader in silicon carbide 3D printing via the IntrinSiC program The company serves industries that require highly durable ceramic parts, particularly for electrical, thermal and semiconductor manufacturing applications.

4. Bosch Advanced Ceramics

Bosch, a global powerhouse, extends its expertise into advanced ceramics for AM, focusing on high-performance parts for applications like automotive sensors, healthcare devices, and industrial machinery. The company uses both Lithoz and 3DCeram systems.

5. CeramTec

Via the CeramCreator Additive Manufacturing program, CeramTeC offers prototyping, consulting on production-ready design and custom manufacturing. Its engineers work with customers to develop unique solutions for challenging application-specific, geometric and technical requirements, using VPP and NPJ technologies.

6. CERHUM

CERHUM is a Belgian service provider specializing in technical ceramics for medical and industrial uses via 3DCeram and Prodways machines. Their focus on biocompatible ceramic implants makes them a standout in the healthcare sector.

7. iLaser

iLaser specializes in precision ceramic components for high-tech industries like electronics and medical devices. Their internally produced advanced laser-based AM solutions ensure high quality and accuracy.

8. Alumina Systems

Alumina Systems is a leader in the production of ceramic parts with a strong focus on energy, electronics, and medical applications. Their expertise in ceramic-to-metal joining also gives them a competitive edge.

9. WZR Ceramic Solutions

WZR is known for its cutting-edge innovations in technical ceramics, offering AM services for specialized applications in aerospace, defense, and automotive industries. The company works with Lithoz (for VPP) as well as Concr3de (for binder jetting) technologies among others

10. Kyocera Fine Ceramics

A globally recognized leader in ceramics, Kyocera provides advanced ceramic AM services for high-tech applications, particularly in electronics and medical devices, where precision and material properties are critical.