Text: Thomas Masuch, 5 November 2024

The latest developments in software for Additive Manufacturing aim to achieve greater efficiency along the entire process chain. The individual innovations set to be shown at Formnext 2024 are aimed at specific processes and tasks, or offer solutions that cover everything from design to production. These new software solutions reflect the trends in the industry and often also enable the automation of AM, or the integration of new AM technologies. Furthermore, specific developments promise better part quality or faster production thanks to better filling strategies, or more efficient operations for dental laboratories.

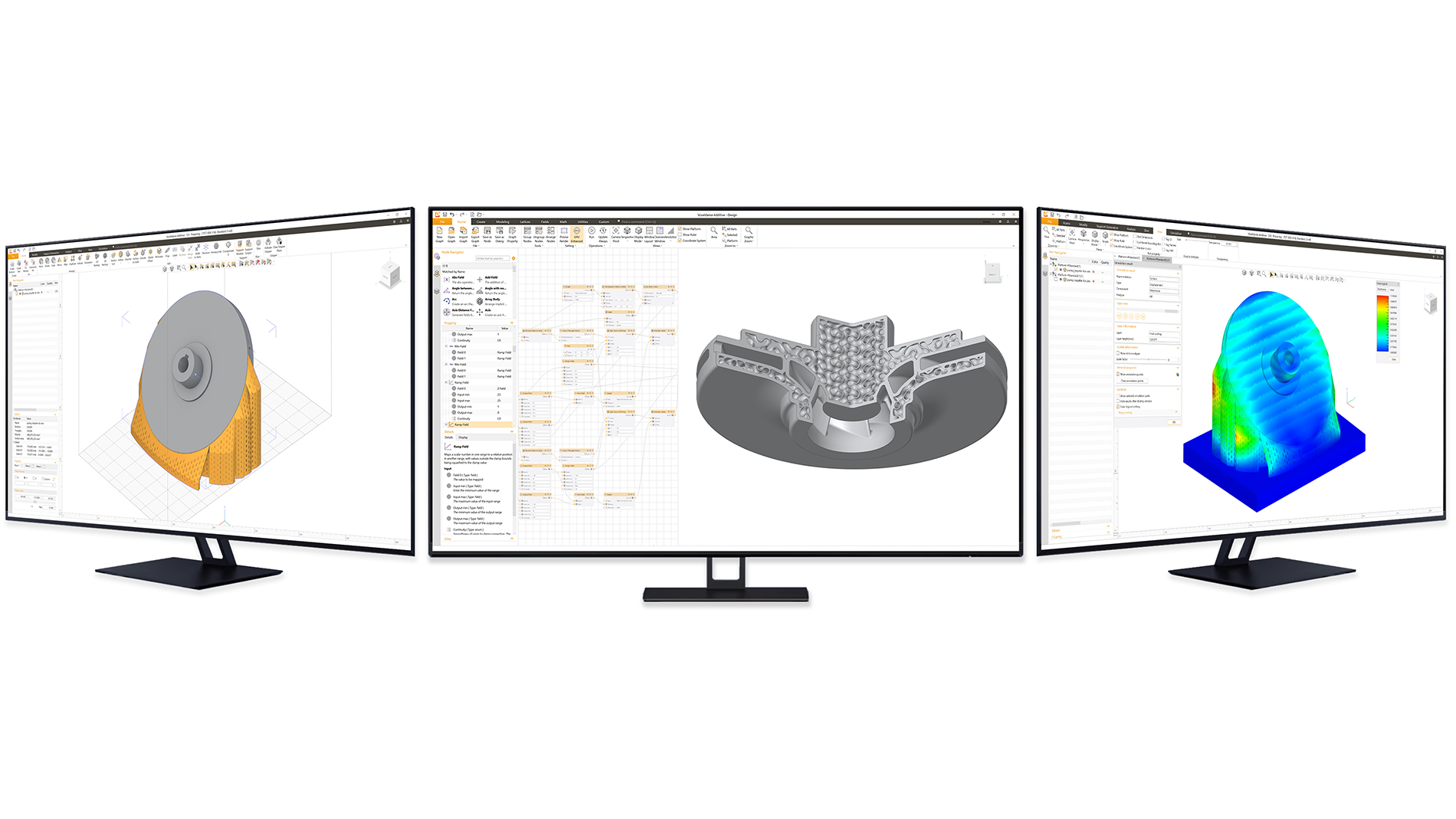

Design and manufacture with one platform

At Formnext, Chinese software provider VoxelDance is presenting VoxelDance Additive 5, a comprehensive software solution that makes it easier to switch between different model formats and, according to the manufacturer, helps to exploit the full potential of 3D printing. “Engineers often face delays and extra costs because of the back-and-forth between design and production stages,” says Zhang Chaoxin, CEO of VoxelDance. “Transferring data from CAD to CAM, for example, can take forever and often results in errors. If model compensation is performed separately in CAM and CAE, it can cause inaccuracies in data preparation.” VoxelDance Additive 5 solves this problem by combining design, manufacturing, and engineering tools in one platform.

Better components thanks to an optimized filling strategy

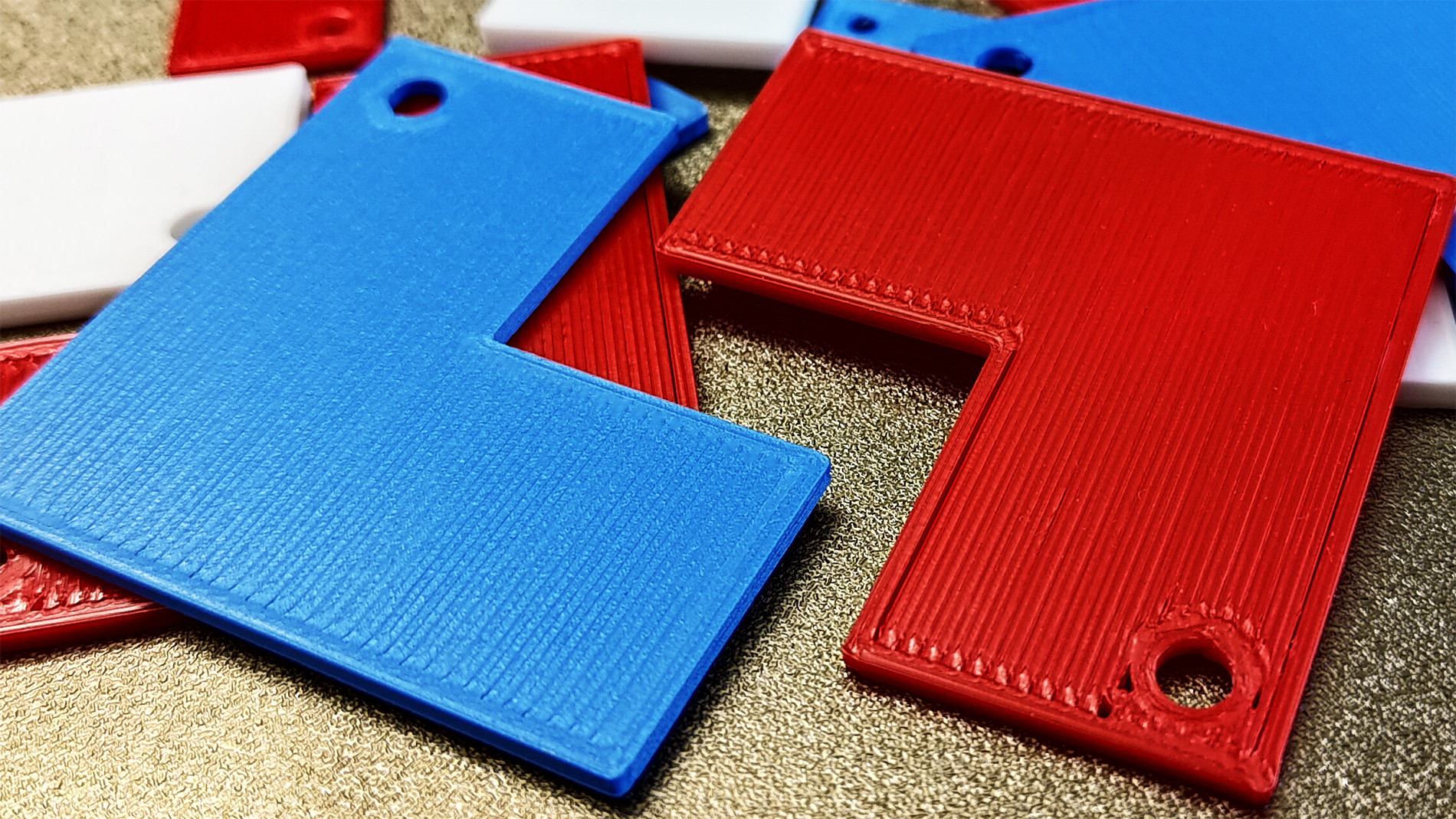

With a strong focus on AI and digital simulations, Advanced Additive says it wants to help shape the future of AM. At Formnext 2024, the company will be presenting its latest innovations in its production software for 3D printing. Advanced Additive is working on AI-for-FLM path planning that makes component-related optimizations in filling strategies, which should enable faster and more reliable production.

New features for automated hybrid manufacturing

Aibuild has updated its software platform to version 3.0, offering a wide range of new features for the automation of additive and subtractive manufacturing processes on one platform. The software is suitable for both metal and plastic processing and makes it possible to plan, execute, monitor, and optimize toolpaths. Aibuild 3.0 includes scanning, damaged part repair, molding, milling, WAAM, DED, and more

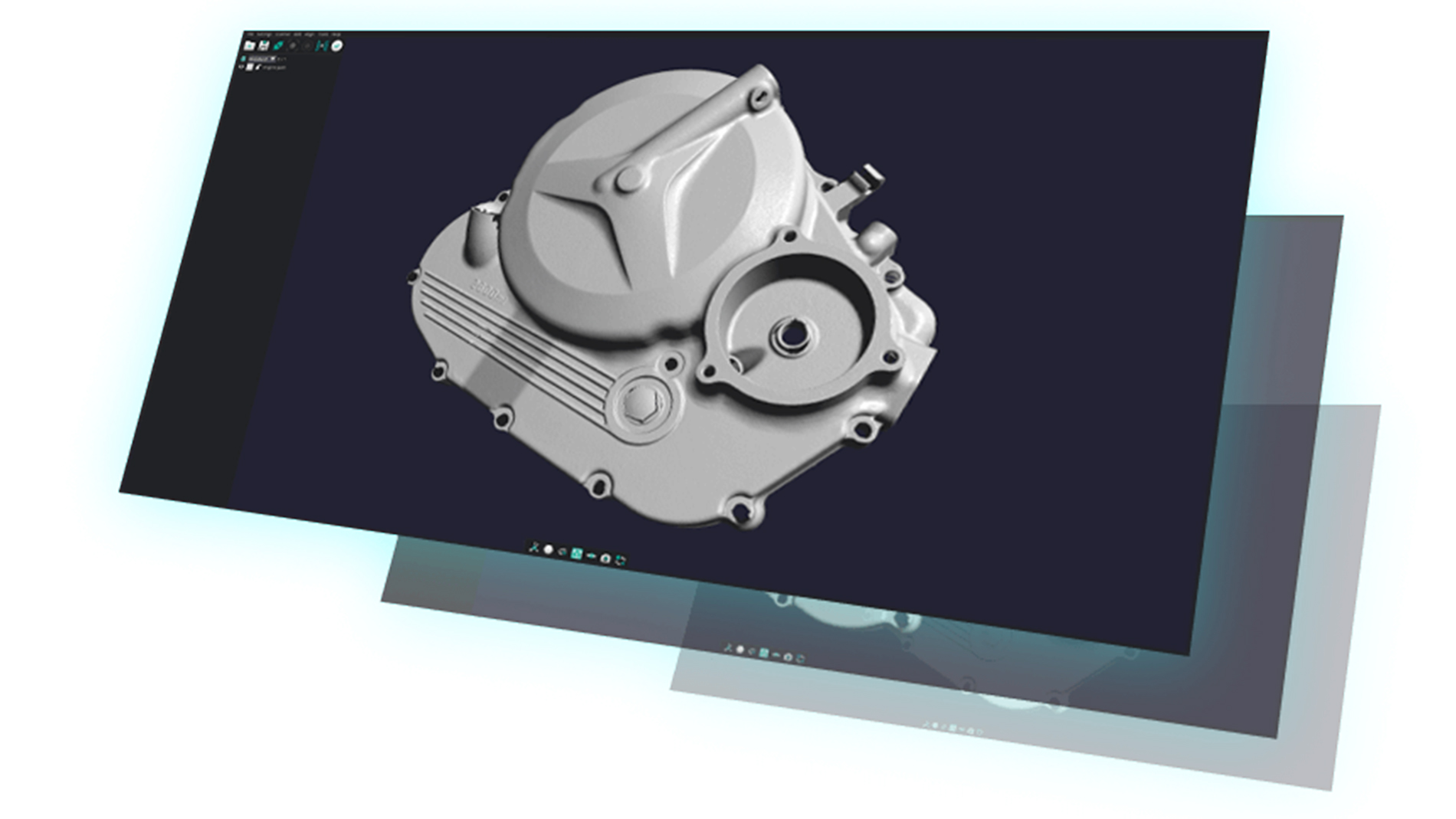

Processing point clouds and meshes

Polyga is presenting its new software platform, PointKit – the US company’s latest effort to optimize workflows for industrial 3D data acquisition, automation, analysis, and reverse engineering. The PointKit platform includes two software tools, PointKit Scan and PointKit View. PointKit Scan offers new alignment and 3D data processing algorithms. Its features include the ability to integrate with existing manufacturing lines to automate 3D capture and inspection, to reconfigure for reverse engineering to ease the mesh-to-CAD process. PointKit View, meanwhile, works seamlessly with PointKit Scan to provide cloud storage and sharing capabilities for easy collaboration from any desktop or mobile device.

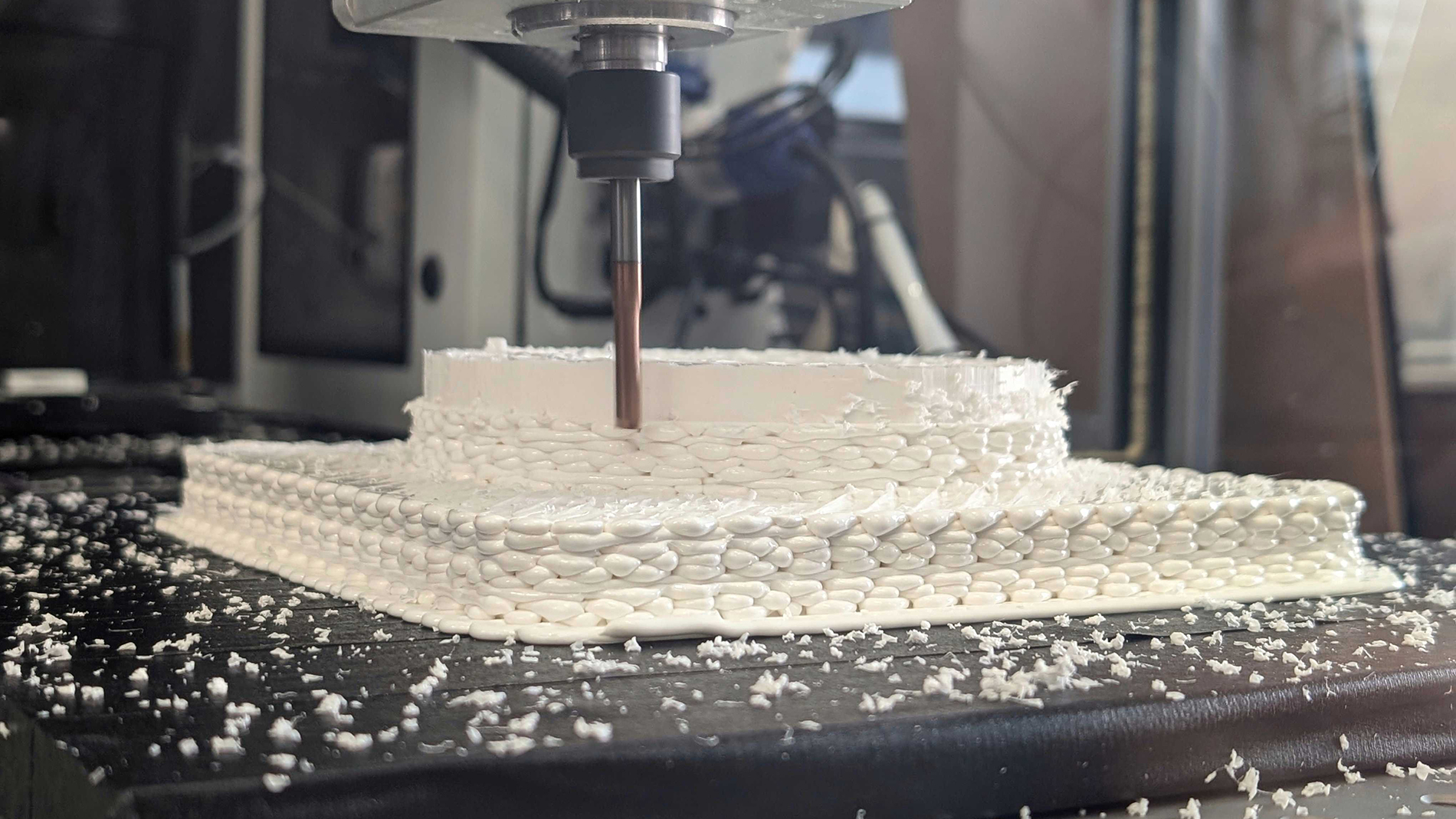

Precise printing and milling

The production of parts using the SLM process is becoming increasingly popular among dental companies. However, the printed restorations must undergo finishing to ensure that they are precise and comfortable. This was why CIMsystem developed Make&Mill, a hybrid solution that combines the advantages of both additive and subtractive technologies in a single application.

AI solution for internal data sets

Fehrmann MaterialsX has developed MatGPT Enterprise, an AI solution that combines the proven functions of MatGPT Pro with the ability to build and use company-specific knowledge. MatGPT Pro is a browser-based AI platform that leverages expert knowledge in specialized fields such as aluminum and magnesium. Like MatGPT Pro, it will be accessible through individual licenses.

FURTHER INFORMATION:

You will find all the companies mentioned at Formnext 2024:

Advanced Additive with Bayern Innovativ: Hall 12.1, Booth C71

Aibuild: Hall 11.1, Booth F39

CIMsystem: Hall 12.0, Booth B63

Fehrmann Materials: Hall 12.0, Booth C81

Polyga: Hall 12.1, Booth G10

VoxelDance: Hall 12.0, Booth C22

Tags

- Additive Manufacturing