29 June 2024

Finnair replaces video monitors in its A320 fleet with lightweight, 3D-printed panels

In addition to safety, weight is one of the decisive criteria in aircraft construction. This is why both aircraft manufacturers and airlines leave no stone unturned when it comes to making their planes lighter. After all, every kilogram saved pays off in the form of lower fuel consumption. Finnair has thus started to remove the heavy, outdated video monitors from the passenger service units (PSUs) of its Airbus A320 fleet. The empty space is to be filled by replacement panels that Finnair has ordered from AM Craft, a Latvia-based AM service provider specializing in aircraft interiors.

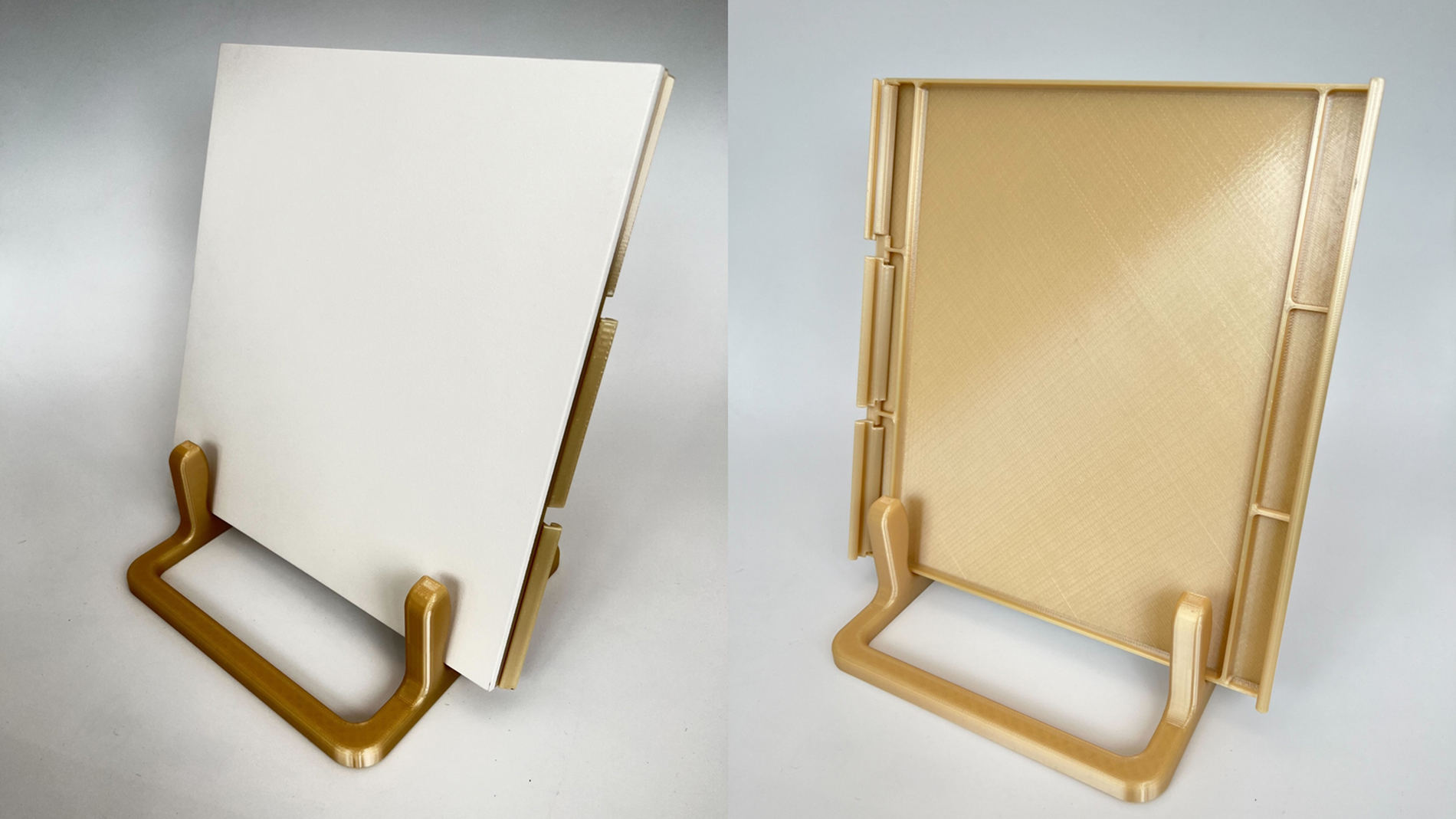

After redesigning them, AM Craft 3D-printed more than 300 of the aviation-certified replacement panels and recently delivered them to Finnair. According to AM Craft, it benefited from its experience in the development, manufacture, and certification of flying parts for the aviation industry. Using Additive Manufacturing, the company was able to design the panels in a weight-optimized way and produce and deliver them on demand. Since AM Craft has EASA 21G Production Organization Approval, it can certify the airworthiness of the parts it produces.

AM Craft used Stratasys' FDM technology and ULTEM 9085 filament to produce the replacement PSU panels for Finnair. It also finished them in its own certified paint shop.

A perfect match for the aviation sector

“This project is a great example of how well additive manufacturing fits within the aviation sector. As the average age of commercial fleets continues to grow, there are many opportunities where it makes sense to redesign a part and produce only the quantity needed. With Additive Manufacturing, we can realize great low-volume, high-mix economics, often while reducing part count and weight in the process,” said Janis Jatnieks, AM Craft’s chief commercial officer. “Without additive manufacturing, this could have been a much slower and more expensive project.”

AM Craft has added the panel to its digital catalog, which makes it "available to Finnair or any other airline that needs this solution for an A320 at any time,” as Jatnieks explains. “Thanks to our network of approved production facilities, we can produce ready-to-install panels locally when they’re needed in Dubai or Singapore and provide them without warehousing or shipping.” The panels can also be printed in various sizes.

FURTHER INFORMATION:

Tags

- Services

- Aviation and aerospace