17 May 2023

The construction industry is considered one of the world's biggest CO2 emitters - the production of cement in particular produces enormous amounts of greenhouse gas. A team from the University of Michigan has now developed a method to drastically reduce these emissions. The new approach, called “Shell Wall,” combines topology optimization and 3D concrete printing.

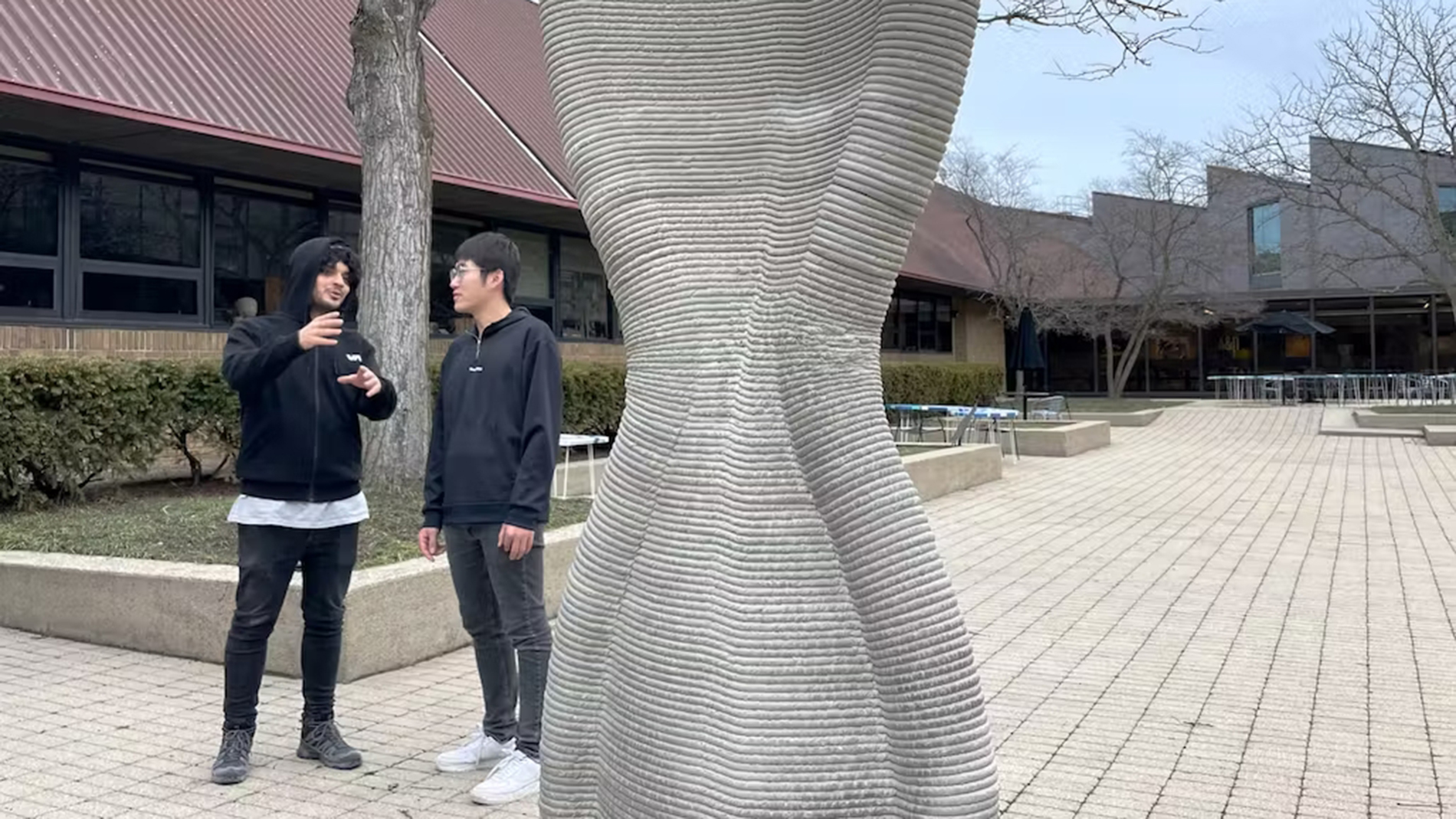

The method was developed by architect Mania Aghaei Meibodi and researchers Alireza Bayramvand and Yuxin Lin of the Dart Lab at the University of Michigan's Taubman College of Architecture and Urban Planning. The production of ultralight, zero-waste concrete is expected to reduce weight by 72 percent compared to conventional, solid concrete of the same size.

Efficient use of materials

At the same time, it also aims to change the way concrete has been printed in the past: conventional concrete printers build horizontal walls that are later stabilized and filled. “This leads to high concrete consumption and limits its application for lightweight forms that entail intricate shapes like branching and angular tubular forms, overhangs, layer cantilevers, and filament section or angle variations,” said Aghaei Meibodi, assistant professor of architecture at Taubman College.

Images: Dart Laboratory

The “Shell Wall,” on the other hand, allows for efficient use of materials by placing the material exactly where it is needed for structural purposes, “and eliminates unnecessary overbuilding with excessive amounts of materials,” says Aghaei Meibodi.

FURTHER INFORMATION:

Tags

- Construction and architecture