Additively manufactured components often require manual post-processing, which can involve everything from simply removing powder or support structures to heat treatment, surface finishing, sorting, dyeing, and quality inspection. As AM sees more and more use in industrial series production, automating these processes is becoming increasingly important as a means of maintaining a constant level of quality and reducing component costs.

According to the second annual Trends Report from PostProcess, such activities also account for 47 percent of corresponding production costs – and yet companies often overlook the post-processing phase when considering which 3D printer to purchase. "That needs to change," says Oliver Elbert, head of Additive Manufacturing at the international mechanical engineering group Grenzebach. "To remain competitive in the market over the long term, companies are also going to have to automate post-processing in their series production."

Specialized automation solutions can minimize manual steps, lower costs, and bring about sustained increases in productivity. "Compared to the preparation and printing phases, however, we’re still seeing the lowest level of automation in post-processing," Elbert continues. "That’s actually where we believe companies can achieve the most benefits for the money they invest."

Up to a 70-percent reduction in production costs

By leveraging intelligent automation and integrating individual process steps in AM, companies can save as much as 70 percent on their production costs. This is why solutions from Grenzebach are drawing considerable interest from 3D printer manufacturers that want to add automation technology to their portfolios. At the same time, Grenzebach also offers a range of benefits to those who are already engaged in Additive Manufacturing and want to automate the processes involved.

From removal to quality control

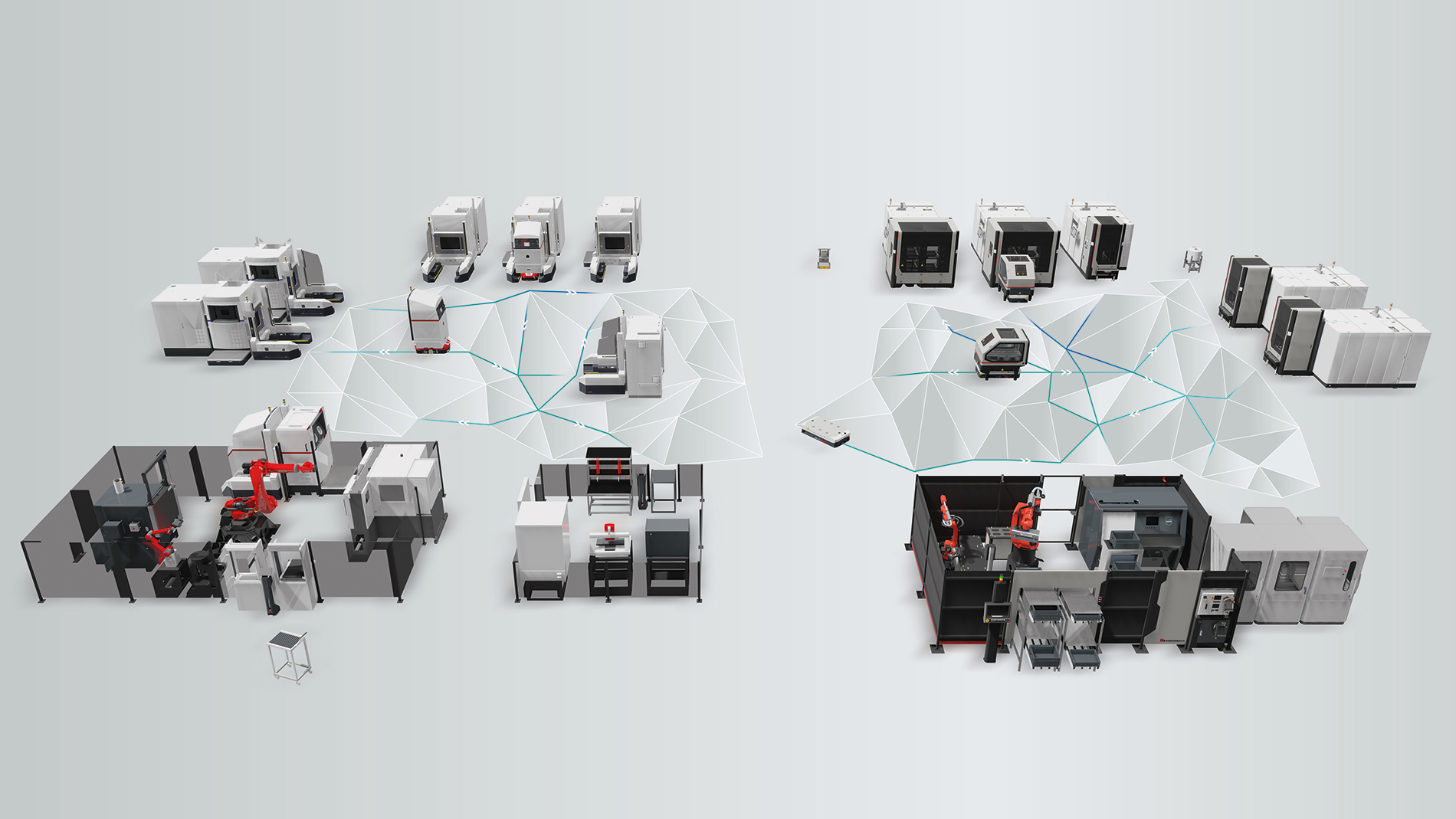

Thanks to its experience in supporting numerous industries as a full-service automation provider, Grenzebach is a partner companies can rely on when making the leap to fully automated powder-based AM. The automation equipment it provides covers everything from exchange solutions for automated printer insertion and removal, dependable depowdering systems, driverless transport vehicles and containers, machine fitting, robotic cells with bin-picking capability, and inspection solutions.

Meanwhile, Grenzebach also works closely with a variety of printer manufacturers – EOS, for example, with which it has developed a shared modules solution for automated post-process chaining. The group is actively involved in research projects like NextGenAM and Polyline, as well. Production facilities in Germany, Romania, the United States, and China and further service locations around the world enable it to provide local support and assistance almost anywhere.

FURTHER INFORMATION:

Grenzebach Maschinenbau GmbH

Asbach-Bäumenheim, Hamlar Germany

Phone: +49906982-2000

E-mail: am@grenzebach.com

www.grenzebach.com/am

Tags

- Automation and handling

- Postprocessing

- Quality management and measurement technology