Text: Thomas Masuch, 5 November 2024

What applies to AM systems for metal also applies to the polymer and ceramic sectors, where productivity is the top priority in new system development. No wonder, as millions of plastic parts are 3D printed every month in the dental sector alone. That means more economical output translates into real money. However, 3D printing systems are also becoming increasingly efficient in the micro and ceramic sectors, and manufacturers are coming up with some ingenious solutions for related purposes. At the same time, Formnext 2024 exhibitors will be presenting specialized equipment for special applications, including in the important field of materials research.

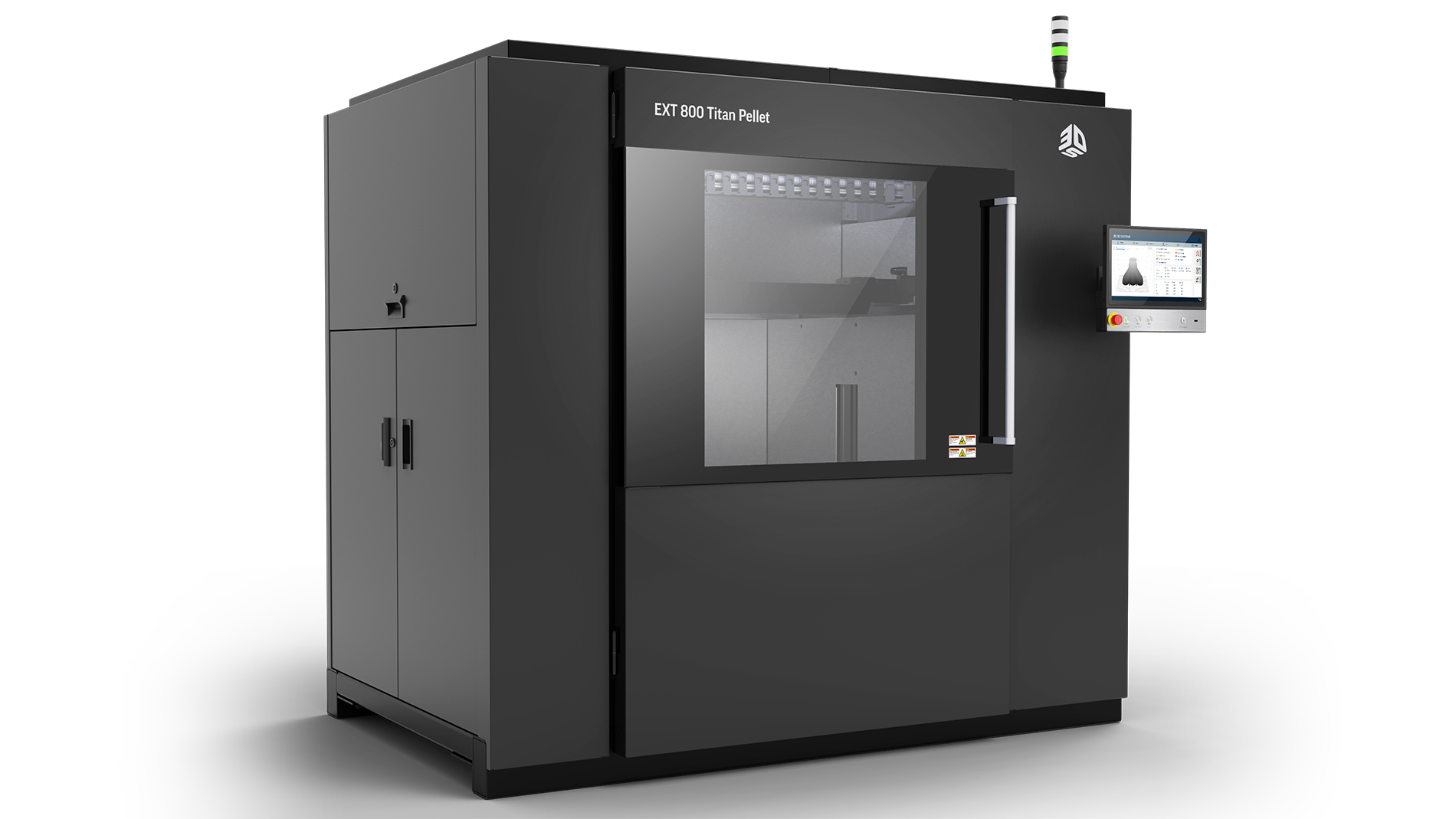

3D Systems will be presenting its approach to implementing demanding applications even more productively at Formnext 2024. The US company's presentation will focus on the new PSLA 270 and EXT 800 Titan Pellet systems. The PSLA 270 is a high-speed, projector-based SLA AM solution designed for the time-sensitive production of large volumes of parts. According to 3D Systems, this mid-frame 3D printer can deliver batch-level, production-grade parts in a fraction of the time it would take for conventional SLA. The PSLA 270 comes with 3D Systems’ 3D Sprint software, which enables manufacturers to efficiently go from design to high-quality, true-to-CAD parts without needing additional third-party software.

Micro-scale components: flexibly varying resolution

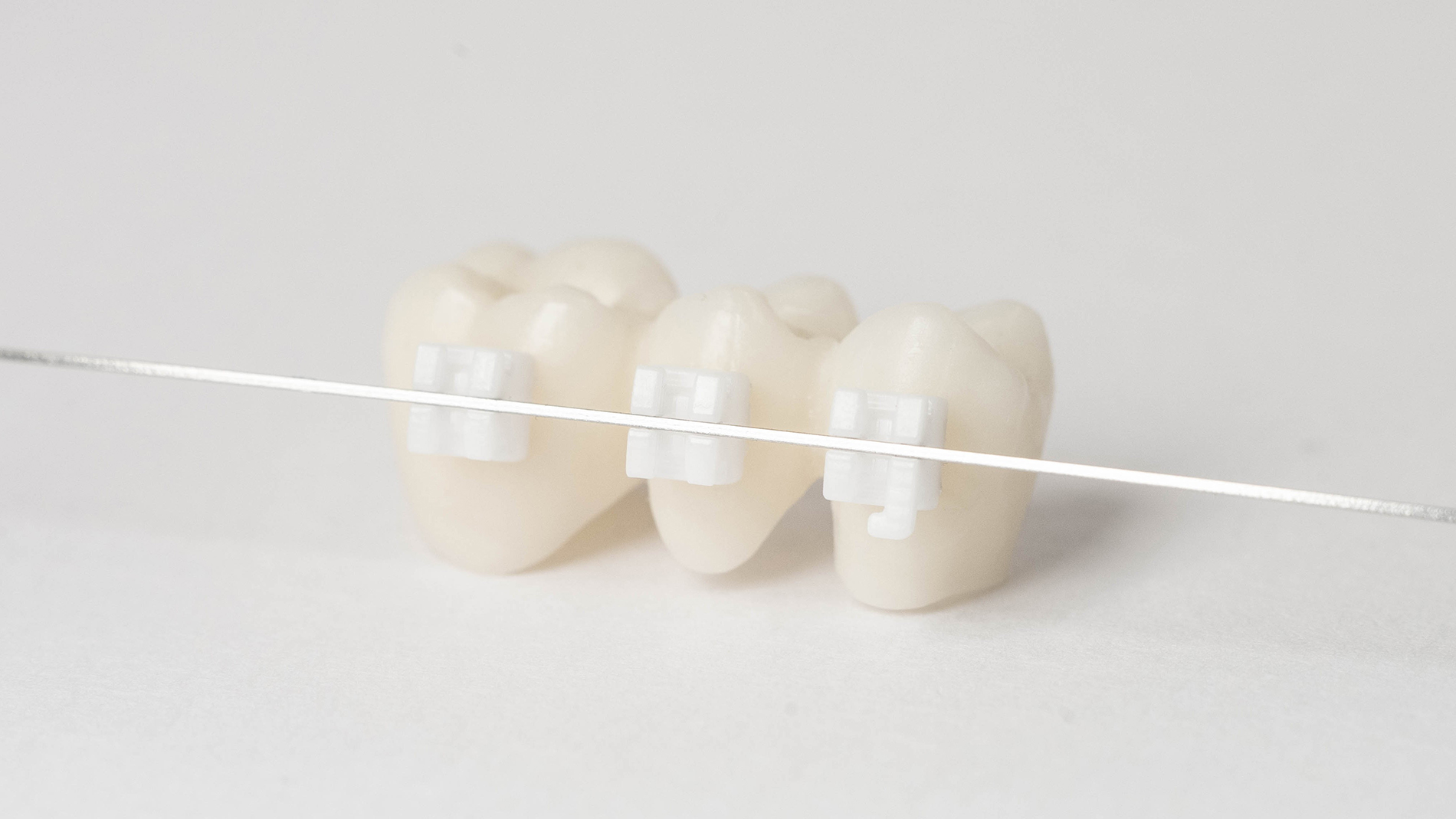

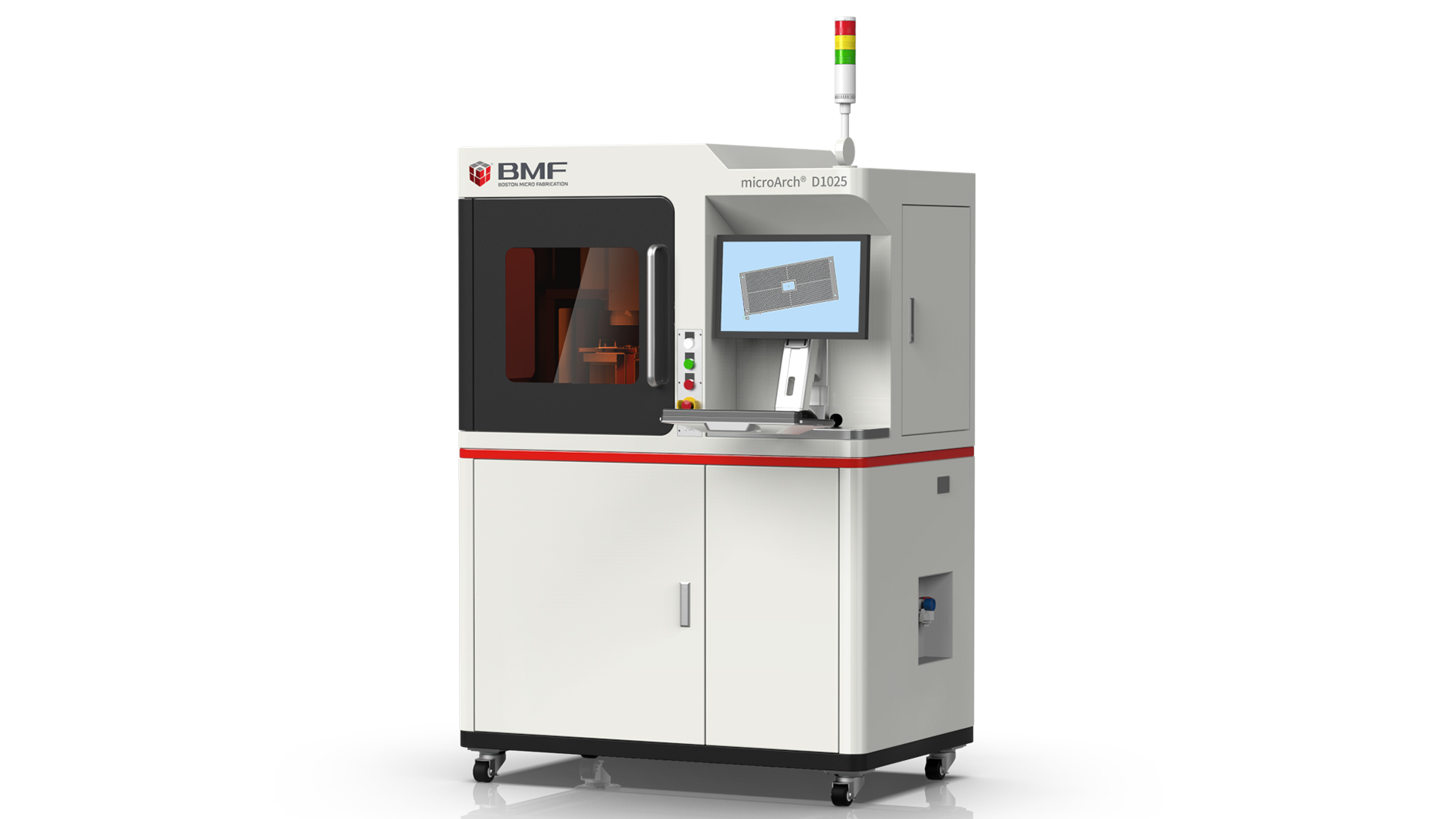

With its next generation of industrial 3D printers for micro-scale components, Boston Micro Fabrication (BMF) is promising a flexible resolution of 10µm or 25µm to facilitate higher speeds and efficiency. The company is set to present the first 3D printer in its new series, the MicroArch D1025, at Formnext. The hybrid printer accurately produces tiny components and complex features at 10µm, while the 25µm mode enables higher printing speeds for small parts that don’t require ultra-high resolution. Both resolutions can be flexibly combined in the same print layer.

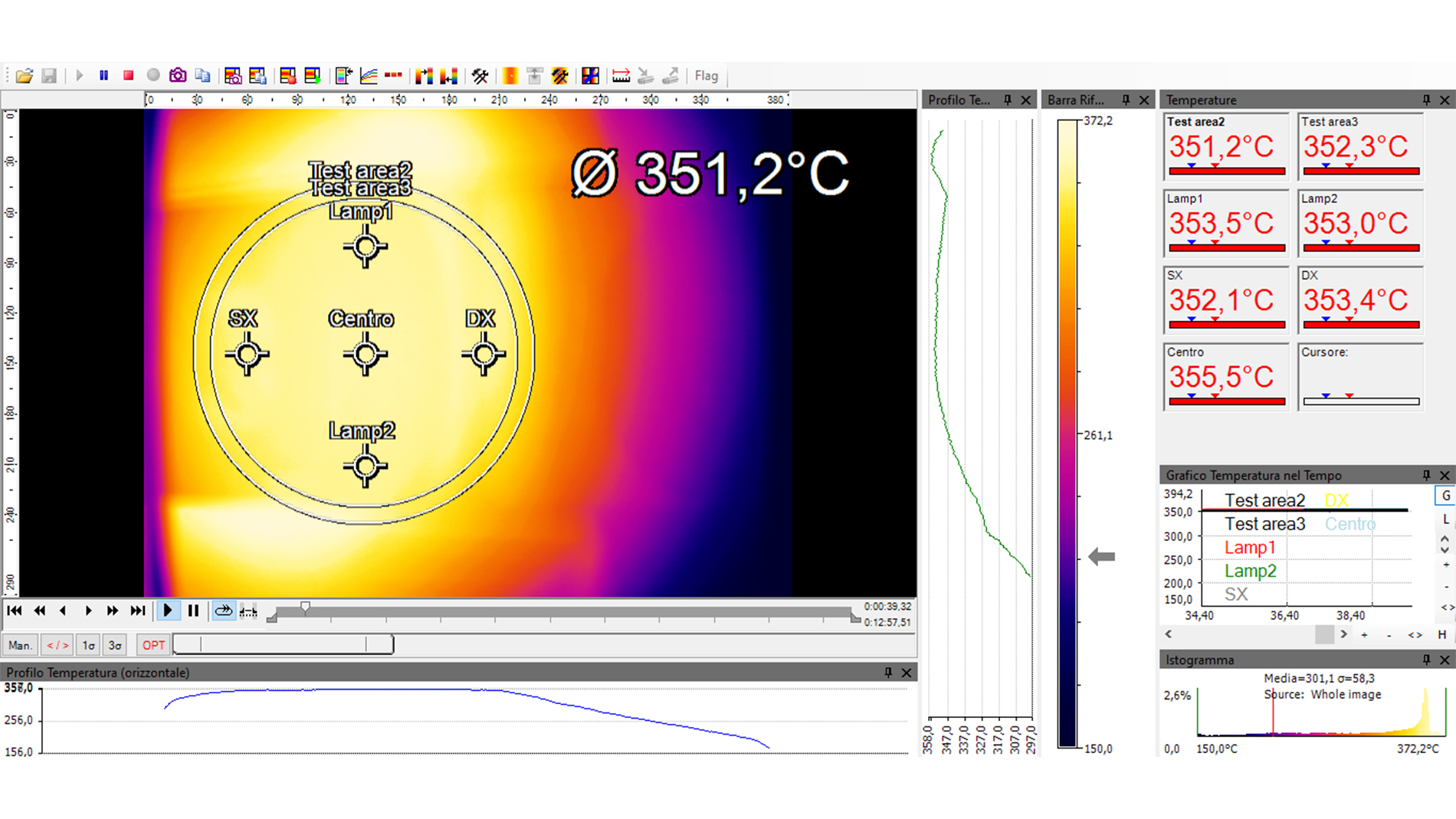

Specially designed for material research

At this year’s Formnext, the Italian company Sharebot is presenting the SnowWhite2 HT, the latest version of an SLS printer that is specially tailored to material research on high-performance thermoplastics. The 3D printer offers a heated powder chamber that can reach temperatures of over 350°C, as well as optimized thermal management and advanced software controls.

Premiere: Much larger build space for ceramic series production

Lithoz will premiere the latest and biggest addition to its range of ceramic 3D printers – the CeraFab System S320. This machine has a build platform and volume that are five times larger than the industry-proven CeraFab System S65, making it suited to the series production of mid-size parts, as Lithoz points out. Also on display will be the newest innovations printed on the S320, including atomic layer deposition ring segments for semiconductor manufacturing, casting cores, and filtration devices. The CeraFab System S320 offers the largest build platform of any Lithoz LCM printer, along with a resolution of 60 µm and a 4K projection system. Lithoz is also promising reduced operating costs thanks to the system’s efficient material usage. Meanwhile, Formnext visitors will be able to examine a showcase of LCM-printed ceramic parts, including segments of an alumina gas distribution ring 15 inches (380 mm) in diameter from Alumina Systems.

FURHTER INFORMATION:

You will find all the companies mentioned at Formnext 2024:

3D Systems: Hall 11.1, Booth D11

Boston Micro Fabrication: Hall 11.1, Booth C19

Lithoz: Hall 11.1, Booth C49

Sharebot: Hall 12.1, Booth E10

Tags

- Additive Manufacturing