10 September 2022, by Thomas Masuch

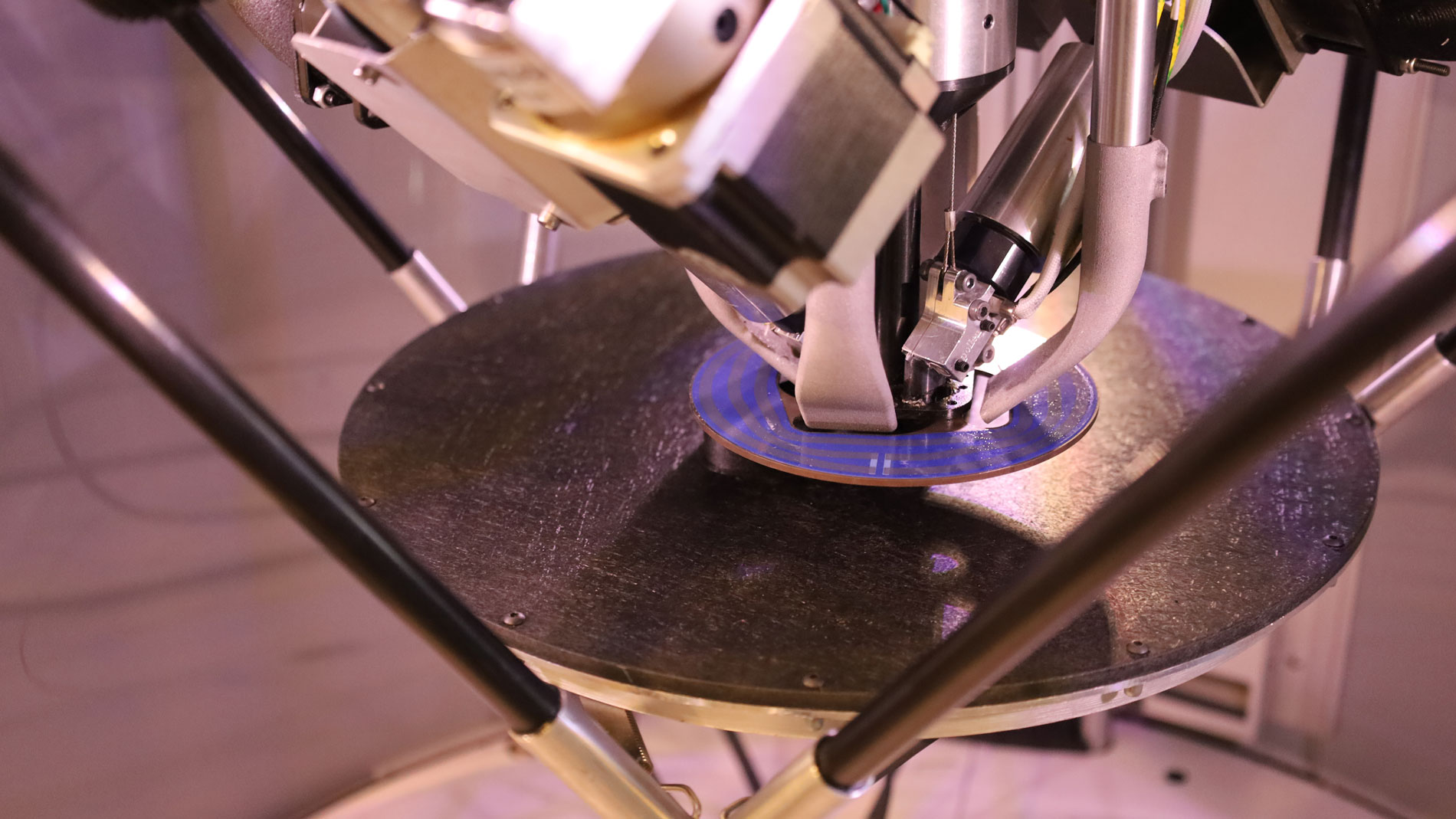

On the outskirts of Paris, Pollen AM develops and produces pellet 3D printers with a clear focus on further growth.

Situated among a school, a residential building, and an industrial hall in the Paris suburb of Ivry-sur-Seine, Pollen AM’s headquarters is a place that used to house a design company. Even today, the artistic flair can still be clearly felt on the premises of this French manufacturer of 3D printers. On seven floors, each of which comprises a single space, its 13 employees work on new technical solutions, marketing activities, or demonstrations of the various possible applications of Pollen AM’s 3D printing solutions in the company’s showroom.

The common theme of these wide-ranging activities is the 3D printing of pellets. "Pellets are the most commonly used materials in industry – from pens to smartphones, basically everything was made from pellets at some point," explains Didier Fonta, the general manager responsible for sales and marketing at Pollen AM. "Even the filaments used in 3D printing were once pellets."

When Pollen AM was founded in Paris in 2013, it was based on the idea of using classic industrial materials for 3D printing. Today, the company offers three series of 3D printers that can additively process a wide variety of materials, from plastics to ceramics to metals. "The big advantage here is that you can use materials that are already certified, and they’re also usually much cheaper than dedicated 3D printing materials," Fonta says, adding that doing so also offers a material advantage in the area of plastics: "We save one heating process and thus achieve the same quality as injection molding."

Connected to the capital

In typical Paris bistros two streets away, people are chatting; the street here is also filled with the mixture of hustle and bustle, style, and diversity that is typical of the French capital. However, the proximity to the center of metropolis on the Seine is also reflected in the rent prices and rather cramped spaces available. Still, Fonta can’t imagine leaving. "We're Parisians, and we don't want to go anywhere else." Why not? "Hard to say – I was born here and I have my environment here. The rest of France is good for vacations," he explains with a smile.

When it was founded, Pollen AM occupied premises at Place de la République in the heart of the city. Later, the company moved to Ivry because the rents here were economically feasible, at least by Parisian standards. Across the street from its winding seven-story headquarters, Pollen AM has rented two more rooms in a kind of shared factory; it uses them for assembling its 3D printers, and also for storage. Next door, a former employee has started his own business as a 3D printing service provider and now supplies Pollen AM with components, including several that are installed in its pellet printers.

Pollen AM's portfolio includes one printer series each for plastic, ceramic, and metal pellets. The company deliberately forgoes offering hardware for post-processing (e.g. ovens or debinding units). "That's because each material requires a specific solution, and sometimes this even varies depending on the manufacturer," Fonta explains. In most cases, he adds, customers have the required technology available anyway, as many partners come from the metal injection molding sector and have many years of experience in this area. "Otherwise, we also work with partners who can provide the right solutions."

The situation is similar when it comes to materials: customers obtain them from familiar sources, while Pollen AM "operates purely as a machine manufacturer; we don't even think about selling materials," Fonta affirms. "We’re like the suppliers of CNC or injection molding machines: First and foremost, we take care of the calibration of the machines so we can give our customers the right recommendations to produce in the best possible way."

Clear focus on further growth

According to Fonta, Pollen AM’s printers are used for things like for prototyping or after-market activities. When it comes to providing spare parts even after many years have passed, 3D printing can often be the more cost-effective solution compared to long storage periods. The technology from Paris is also used in the tooling sector, and its customers include both corporations and small and medium-sized businesses. If a customer needs so few parts that buying a printer isn’t worth it, Pollen AM occasionally produces them as a service provider, as well. According to Fonta, however, this is only a very small part of its business. "Above all, we want to sell machines,” he states.

The increased demand for Pollen AM's 3D printing technology is also reflected in the company's growth. In the past two years, its workforce has doubled, and it expects to hire another four employees by the end of 2022. This is partly because during the Covid-19 pandemic, Pollen AM focused on developing digital services. "We've also been able to add important customers in the aerospace sector, and we've been awarded two important funding projects from Île-de-France," Fonta reports.

According to Pollen AM’s general director, the fact that 3D printing currently has such good prospects in France is also due to a change in attitude in politics and industry. "A few years ago, there was still a belief in the need to become ‘fabless’ – in other words, to get by without manufacturing and production,” Fonta explains. “Now that people have realized it was the wrong direction, they’re trying to get an industry going again."

In the future, the company plans to remain focused on further growth. "To that end, we invest around 20 percent of our sales in technical development," says Fonta, who points out that leveraging its business success to position itself even better for the future is important to Pollen AM’s owners and investors.

Meanwhile, Pollen AM’s growth has been largely organic in recent years because it is operated like an independent family business. Shortly after the company was founded, a number of private individuals invested in the company, including members of the founders' families and individuals with industrial experience "who helped us a great deal in making the right decisions as the company continued to develop," Fonta explains. "The fact that no traditional funds or large corporations have joined us has allowed us to remain very independent."

Fonta has a lot of ambitious plans for Pollen AM’s ongoing growth, especially in the field of ceramics. In January 2020, the company presented its PAM series MC printer specifically for this material. By the end of 2022, it also plans to open a branch dedicated to the ceramics sector near an important partner in Mons, Belgium.

FURTHER INFORMATION:

Tags

- Additive Manufacturing