4 June 2024

Multi-material applications were one of the trending topics at Formnext 2023. Now, Quadrus Corporation's Advanced Manufacturing Division (QAMD) has developed the world’s first bimetallic injection nozzle for a rotating detonation rocket engine (RDRE). This breakthrough, which was produced using selective laser melting (SLM), stems from a Small Business Innovation Research (SBIR) project series led by engineers from NASA's Marshall Space Flight Center.

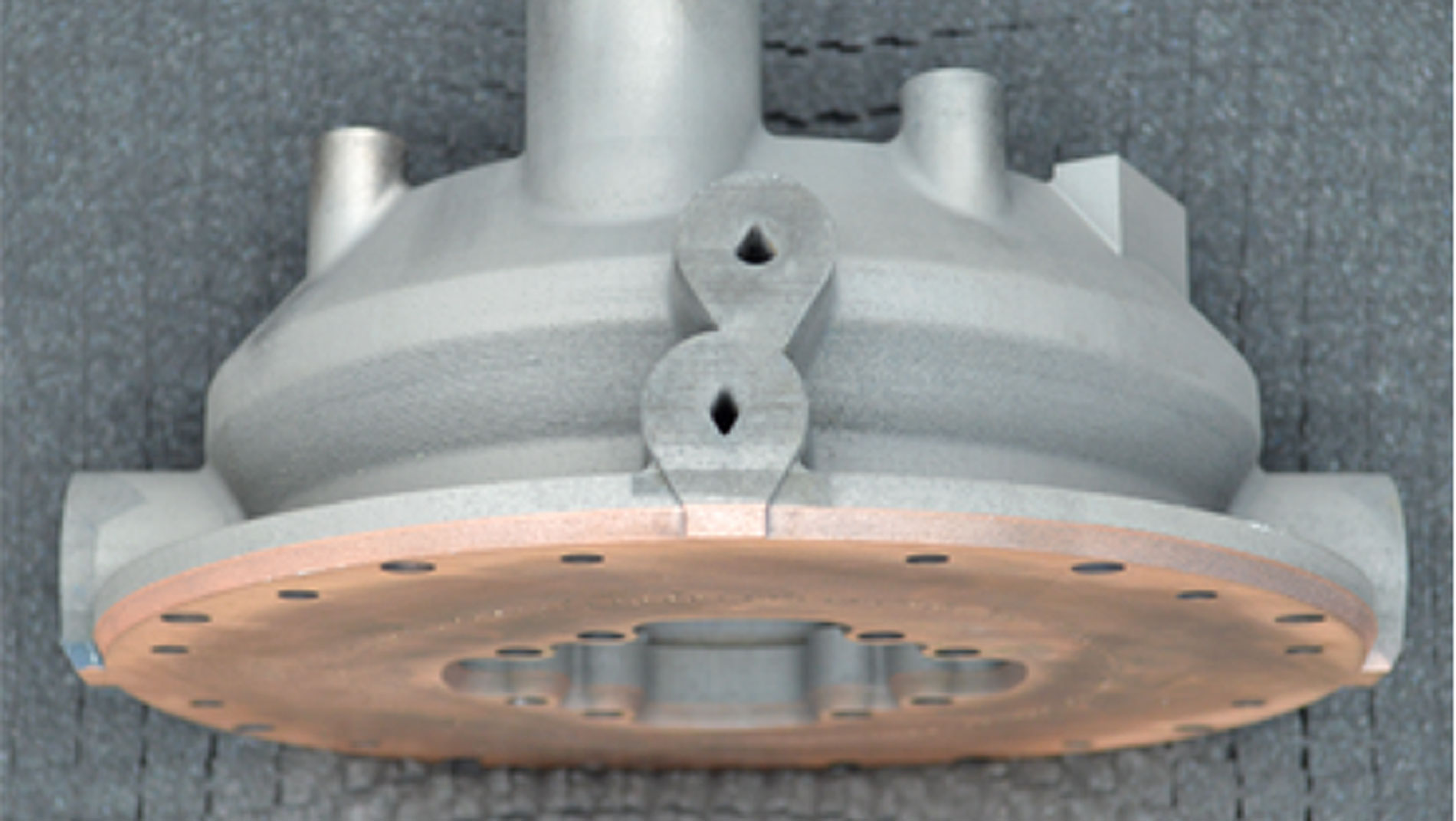

RDRE injectors face significant challenges due to the intense heat generated by spinning detonation waves. In response, QAMD manufactured a solution featuring a thin faceplate made of thermally conductive GRCop-42 and a manifold made of the oxidation-resistant, nickel-based superalloy Monel K500. GRCop-42 allows propellants to effectively cool the injector face, while the oxidation resistance and strength of Monel K500 makes thinner walls possible in the manifold, resulting in a lighter design solution.

Quadrus Corporation’s advanced manufacturing process overcomes numerous hurdles associated with bimetallic SLM fabrication, including precise geometrical alignment, the risk of material cross-contamination, and the formation of high-strength bimetallic bonding. QAMD has demonstrated strict attention to detail in all three areas while maintaining an orifice hole of 0.040 inches through the bimetallic region.

The bimetallic injector represents the culmination of a multi-year effort by NASA and SBIR to focus on thermal management in combustion injector applications. A key accomplishment along the way involved developing Quad Mesh, a groundbreaking approach to transpiration cooling for injector faceplates. Quad Mesh enables customizable permeability in high heat flux regions while synergistically complementing the SLM build process and depowdering techniques.

The bimetallic injector, along with a monolithic GRCop-42 injector that includes Quad Mesh technology, is slated for hot fire testing at the Marshall Space Flight Center during the summer of 2024.

FURTHER INFORMATION:

Tags

- Materials

- Aviation and aerospace