20 January 2025

Fraunhofer ILT has developed an extremely fast technology for applying additive coatings to bipolar plates.

Bipolar plates for fuel cells play an important role in the energy transition and the switch to hydrogen drives. Their mass production takes place every second. In the National Action Plan for Fuel Cell Production (H2GO), the Fraunhofer Institute for Laser Technology ILT in Aachen is working with 18 institutes of the Fraunhofer-Gesellschaft society (including the neighboring Fraunhofer Institute for Production Technology IPT and the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz) to break new ground: Instead of milling its corresponding tools from solid material, it is using extremely high-speed laser cladding (EHLA) to apply wear-resistant functional layers close to the final contour of inexpensive structural steel.

This significantly reduces the costs, construction time, and wear associated with these highly stressed and precisely structured forming instruments. The EHLA process, which Fraunhofer ILT has developed itself, is also key in repairing damaged and worn tools, which contributes significantly to circular economy.

Powder absorbs laser energy

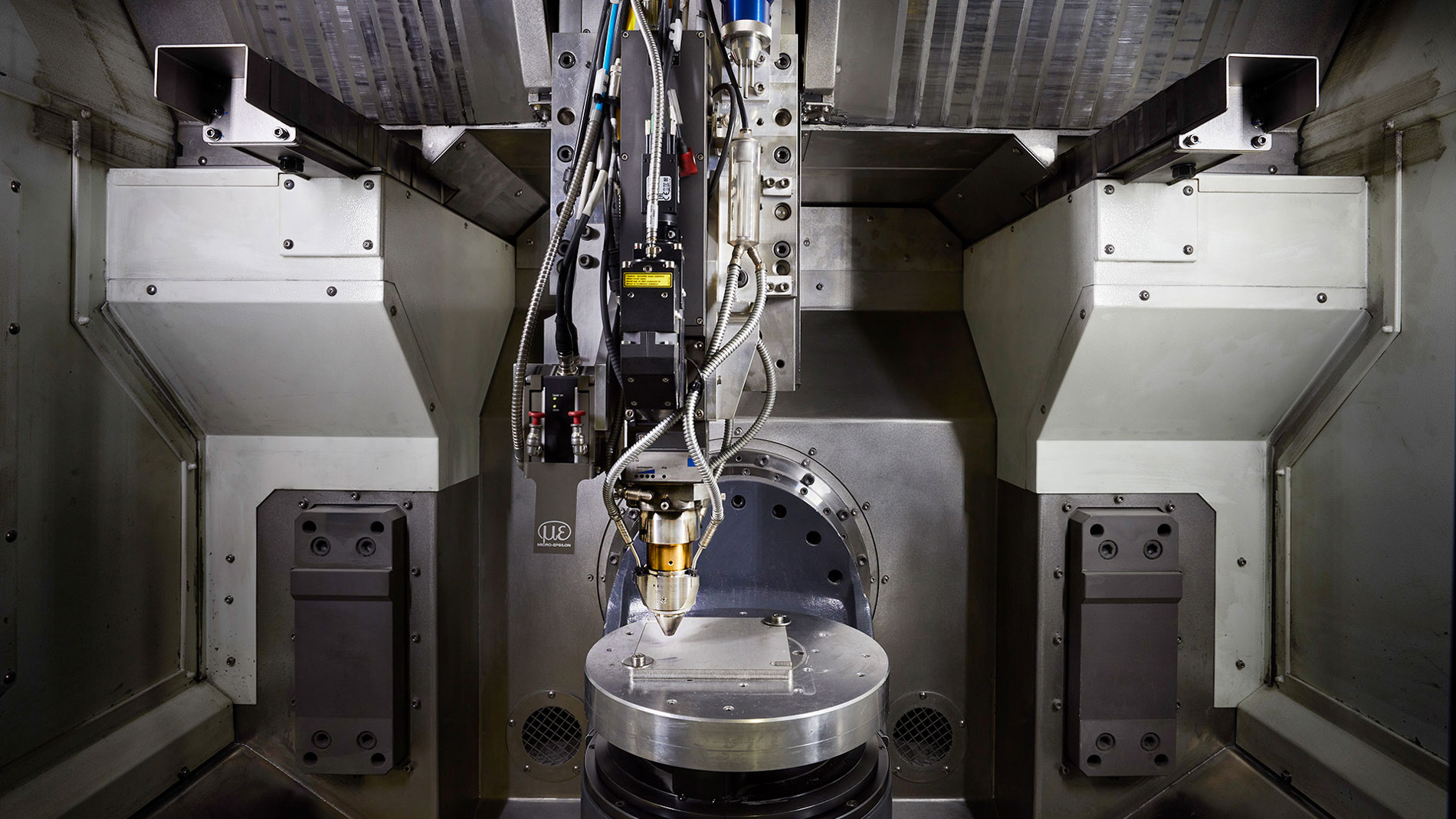

Modern 3D systems that take advantage of EHLA achieve speeds of more than 30 meters per minute. Thanks to digital process chains, wear-resistant functional layers can be applied quickly and efficiently using this additive process. In addition, the three-dimensional material structure can be controlled so precisely that the highly durable layers welded onto low-cost structural steel come very close to the intended final contours.

What makes the EHLA process so special? The powder melts above the workpiece in the laser beam – in other words, it is already in liquid form when it is deposited on the surface. “In the EHLA process, it isn’t the component, but the powder that absorbs a large part of the laser energy before it hits the workpiece,” explains Viktor Glushych, group manager in Coating LMD and Heat Treatment at Fraunhofer ILT. This patented process significantly accelerates the deposition process compared to conventional laser cladding processes, minimizes the thermal load on the components, and creates more homogeneous microstructures in the metal layers. This in turn improves wear resistance.

Increased resistance to wear

The coating materials used in the ongoing H2GO research project are the high-speed steel 1.3343 and the martensitic stainless steel alloy Ferro55, both of which feature high degrees of hardness and wear resistance. The wear protection can be applied at a coating speed of 30 meters per minute; a coating thickness of approx. 1.2 millimeters is achieved per layer. The required coating thickness can be set by applying several layers of one millimeter each. The digital control system ensures that the material is formed precisely and selectively – an advantage that makes it possible to produce robust wear-protection coatings. According to the Fraunhofer team's findings, the coating structure is even more important for guarding against wear than the hardness of the underlying material. “This is because wear resistance depends to a very high degree on the microstructure of the material,” Glushych says. “EHLA produces extremely fine-grained microstructures, which improve the mechanical properties and significantly reduce abrasion.”

Tools with multiple lives

The team is also focusing on the efficient production and reuse of tools. “We are already in contact with companies that manufacture tools for bipolar plates and have received very positive feedback,” Glushych explains. The option to recondition worn tools using the same EHLA process has also resonated with users: Instead of having to melt down tools at the end of their service life, the industry can rebuild their defective or worn contours and refinish them mechanically using EHLA in accordance with digitally stored construction plans. Once a tool wears out, users can thus mill the layer back to a defined contour on-site and coat it again using EHLA. As the Fraunhofer researchers are keen to point out, this procedure “conserves resources and facilitates the long-term use of tools”.

FURTHER INFORMATION:

Tags

- Additive Manufacturing

- Energy