09 September 2019

The young jewelry designer Marie Boltenstern uses Additive Manufacturing to create her collections – working hand in hand with Formrise and DyeMansion. She takes her inspiration from nature.

For more than 50 years, the name Boltenstern has been synonymous with high-quality jewelry, out-of-the-ordinary designs, and the finest work with precious metals. In the 1960s, painstaking craftsmanship and the skillful use of gold enabled founder Sven Boltenstern to secure his place on the global jewelry market. The company has enjoyed fresh impetus since 2015, when his daughter Marie Boltenstern took up the post of CEO & Head of Design, steering the family business in a new direction. If you visit the showroom she opened in 2017 at Bräunerstrasse 11 in Vienna, this is immediately apparent from the storefront. These days, Boltenstern’s tagline is »3D printed fine jewelry«. »Our goal is to integrate innovation into every part of the jewelry business. From designing pieces right through to our customers’ shopping experience,« says Marie Boltenstern.

All of the young designer’s collections are now produced using industrial 3D Printing and then augmented with handmade elements. As she explains, her jewelery takes its inspiration from the forms of nature: »Nature is essentially very geometrical. Although natural artifacts appear organic, they follow fixed mathematical rules and patterns. I incorporate this in my designs.«

Finishig in Style

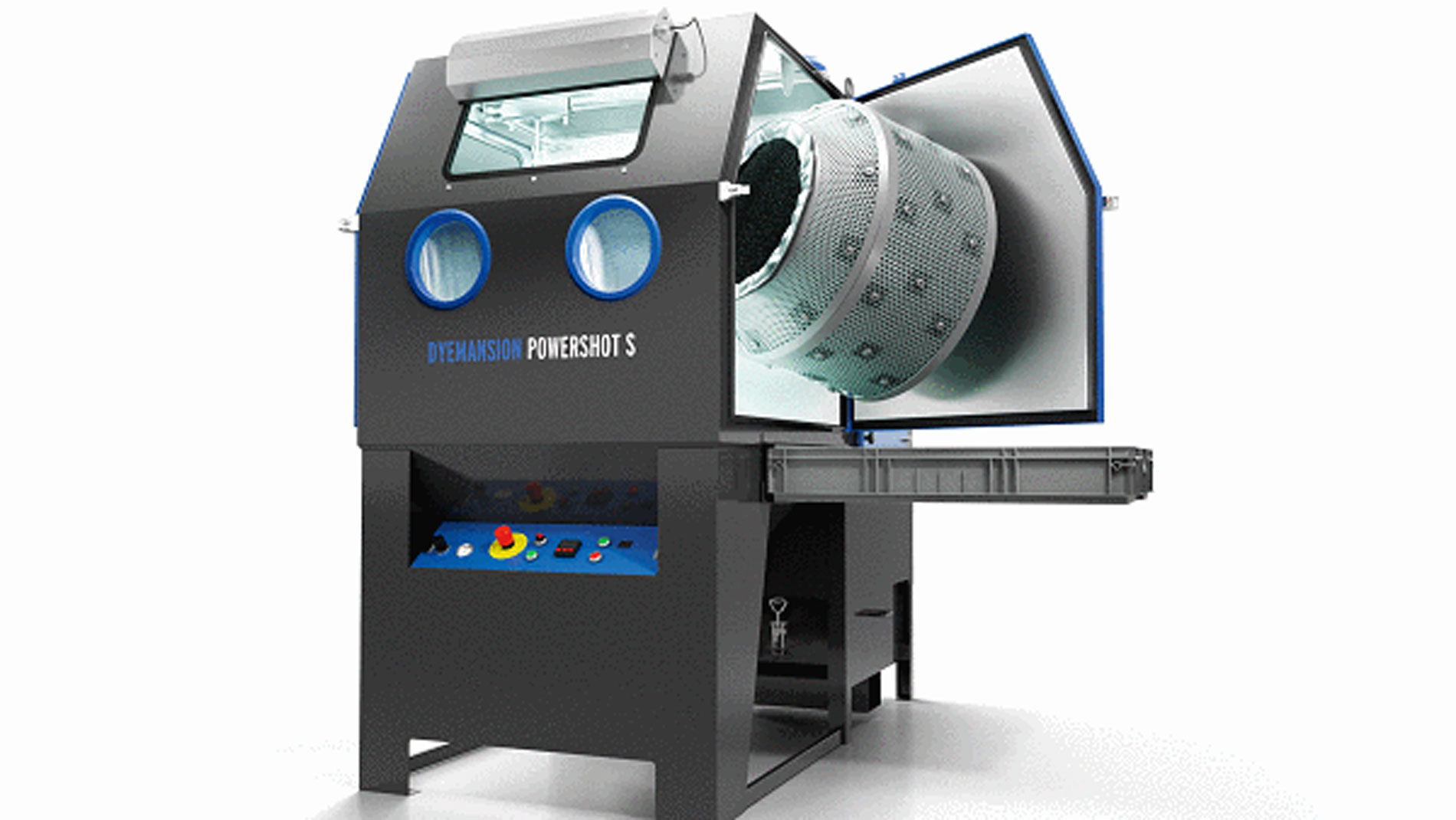

Marie Boltenstern prints jewelry from various Materials, for example also from gold. But she has always worked with polyamide - in the past, however, only for prototyping new structures. »Polyamide has always been a way for us to test new structures,« she says. In addition to enjoying working with the material, the designer realized it was suitable for series production. But during initial trials with the laser sintering process, the layers of the printing process remained visible. The feel of the pieces also failed to meet the requirements for products worn next to the skin. What’s more, thin-walled pendants broke during the tumbling process. And when it came to the intended variety of colors, the white polyamide parts from the 3D printer posed a real challenge. The jewelery manufacturer finally found the solution to these challenges by cooperating with German 3D printing service provider Formrise. Here the polyamide parts of the Fabnora earrings are produced on a Formiga P 110 from EOS. Formrise uses the DyeMansion Print-to-Product workflow for cleaning, surfacing, and coloring. To achieve a better feel and a matt finish, the components are depowdered and finished on a Powershot C and a Powershot S – automatically and without damaging the surfaces. The process takes 10 minutes and does not remove any material. Finally, the earrings are given their chosen color in the DyeMansion DM60 with DeepDye Coloring. The cooperation with all partners has established a reliable and reproducible production process.

Special seasonal Colors

Once the earrings have gone through the three-hour Print-to-Product workflow, they are joined to the handcrafted gold or silver ear studs. The Vienna showroom features earrings in an impressive array of sizes and colors, ranging from blue, purple, pink, and red to orange, yellow, green, and black. On seasonal occasions, the collection is rounded out by additional RAL colors, such as dark green and dark red at Christmas. Because the Fabnora collection and additive production have proven their worth, Marie Boltenstern is planning to expand the collection – for example, by adding new colors and possibly even customized colors in line with customers’ specific wishes. Thanks to the technologies and the dyeing solution deployed, there are virtually no limits to what the designer can dream up and put into practice.

Tags

- Materials

- Surface treatment

- Tool and die making

- Watches and jewelry