15 February 2024

The world's leading AM companies use Formnext to present their latest innovations, as the 2023 edition once again confirmed. It featured numerous product launches, some of which were celebrated with elaborate shows and met with a great deal of interest from experts. At the Stratasys both, for example, CEO Dr. Yoav Zeif presented the F3300 for the first time. With this new FDM printer, the company is promising 25 percent lower costs per part, twice the throughput of conventional FDM printers, and 25 percent higher accuracy.

Markforged president and CEO Shai Terem also traveled to Frankfurt to present the new FX10 to a large audience. According to Markforged, the FX10 is optimized for the on-demand production of spare parts and tools and uses various automation functions to simplify the printing process.

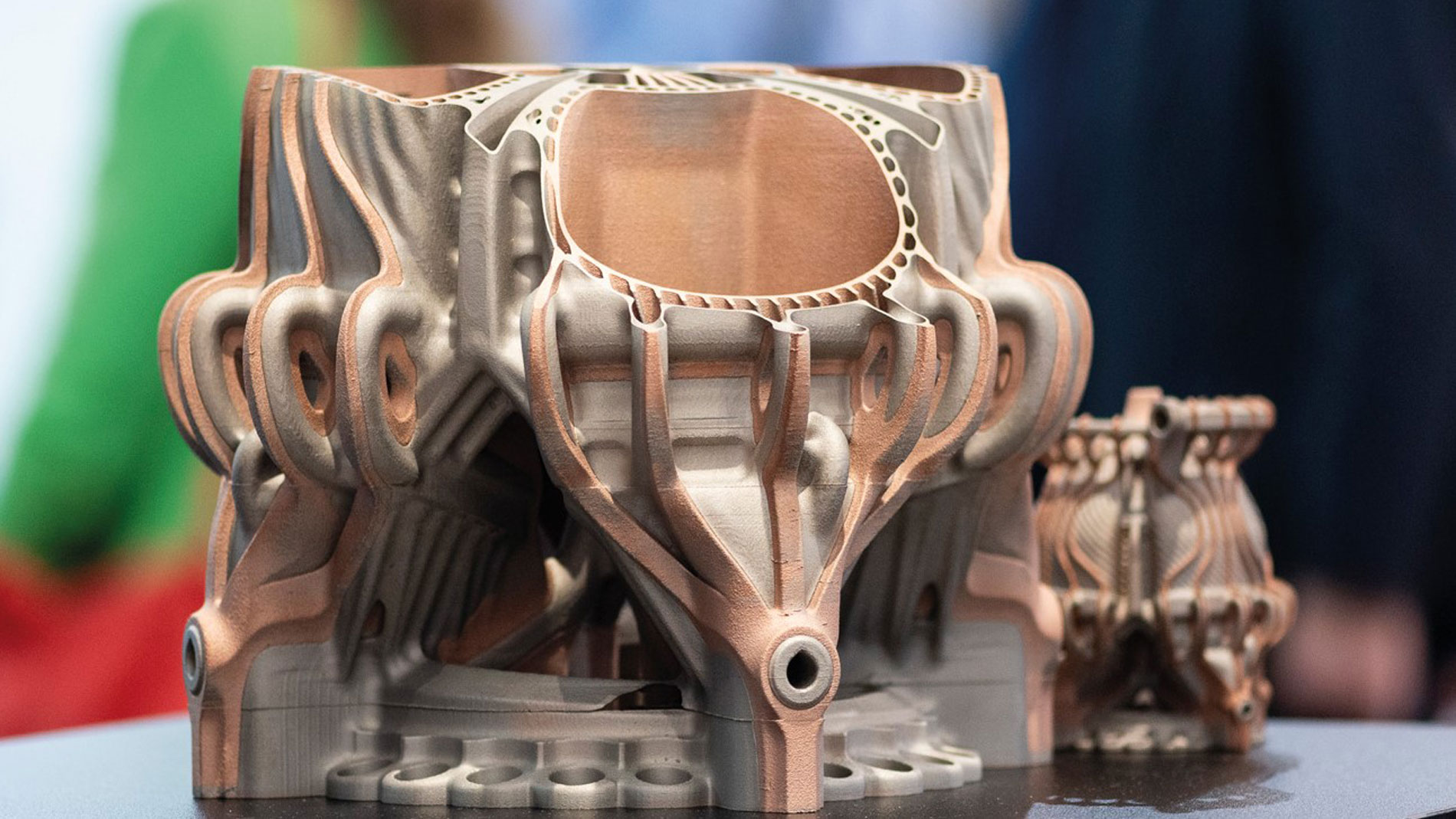

In terms of applications, multi-material printing was one of the top trending topics at Formnext 2023. They are opening the door to more and more uses that were previously impossible in the desired dimensions, including the aerospike rocket engine (which can also be found on the cover of Fon Mag issue 01 2024).

Ideas involving this extraordinary propulsion design are nothing new, having been the subject of research since the 1950s. However, it appears that they were waiting for Additive Manufacturing to arrive and make this technological work of art possible. The engine above was presented by the Fraunhofer Institute for Casting, Composite, and Processing Technology (Augsburg). It was manufactured from a combination of maraging tool steel (1.2709) and the copper alloy CW106C using an LPF process.

Tags

- Additive Manufacturing

- Formnext News