Find instead of search – our market directory offers a comprehensive overview of providers, suppliers, manufacturers and the latest solutions and products for Additive Manufacturing with detailed profiles of all Formnext exhibitors.

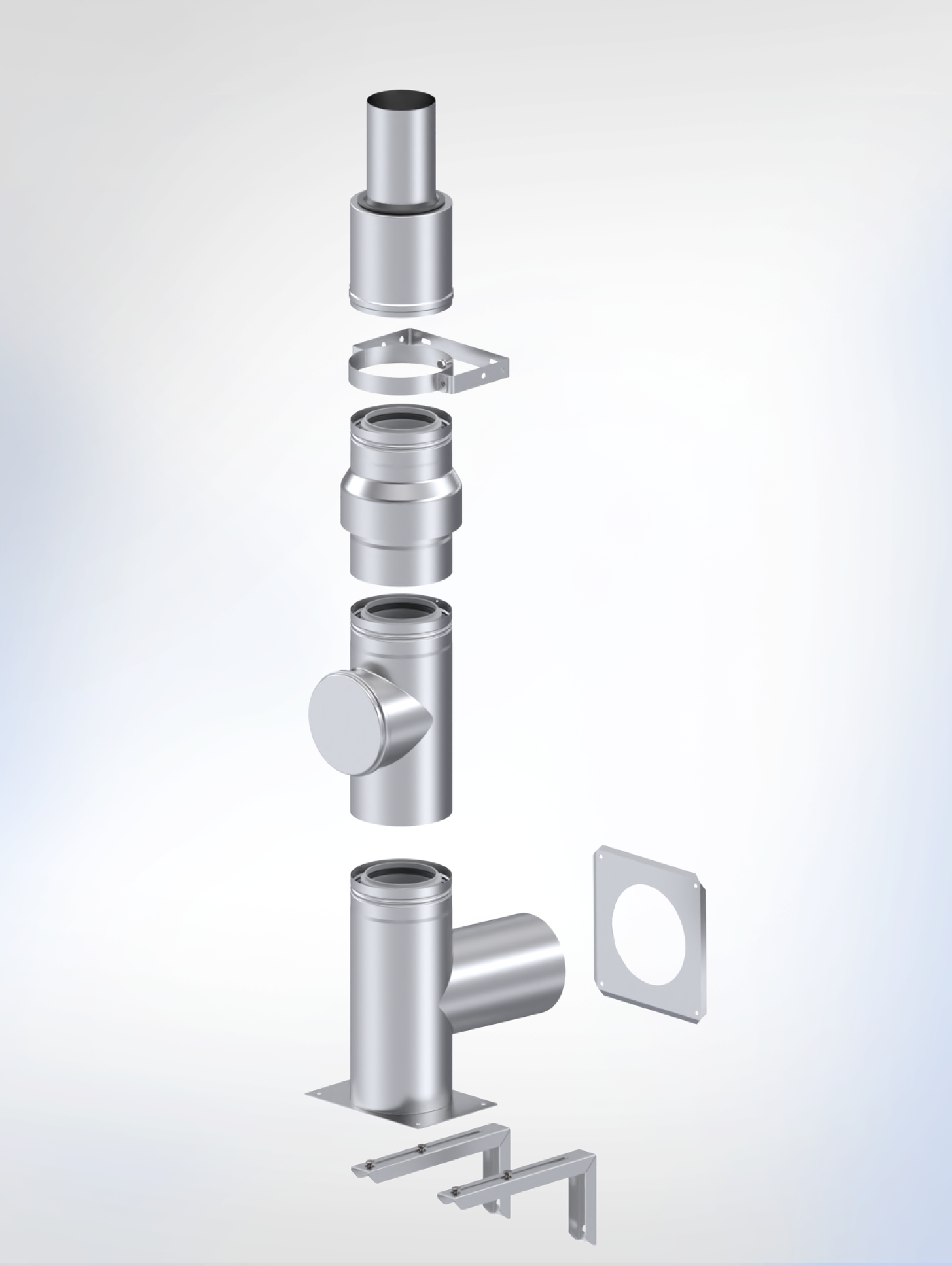

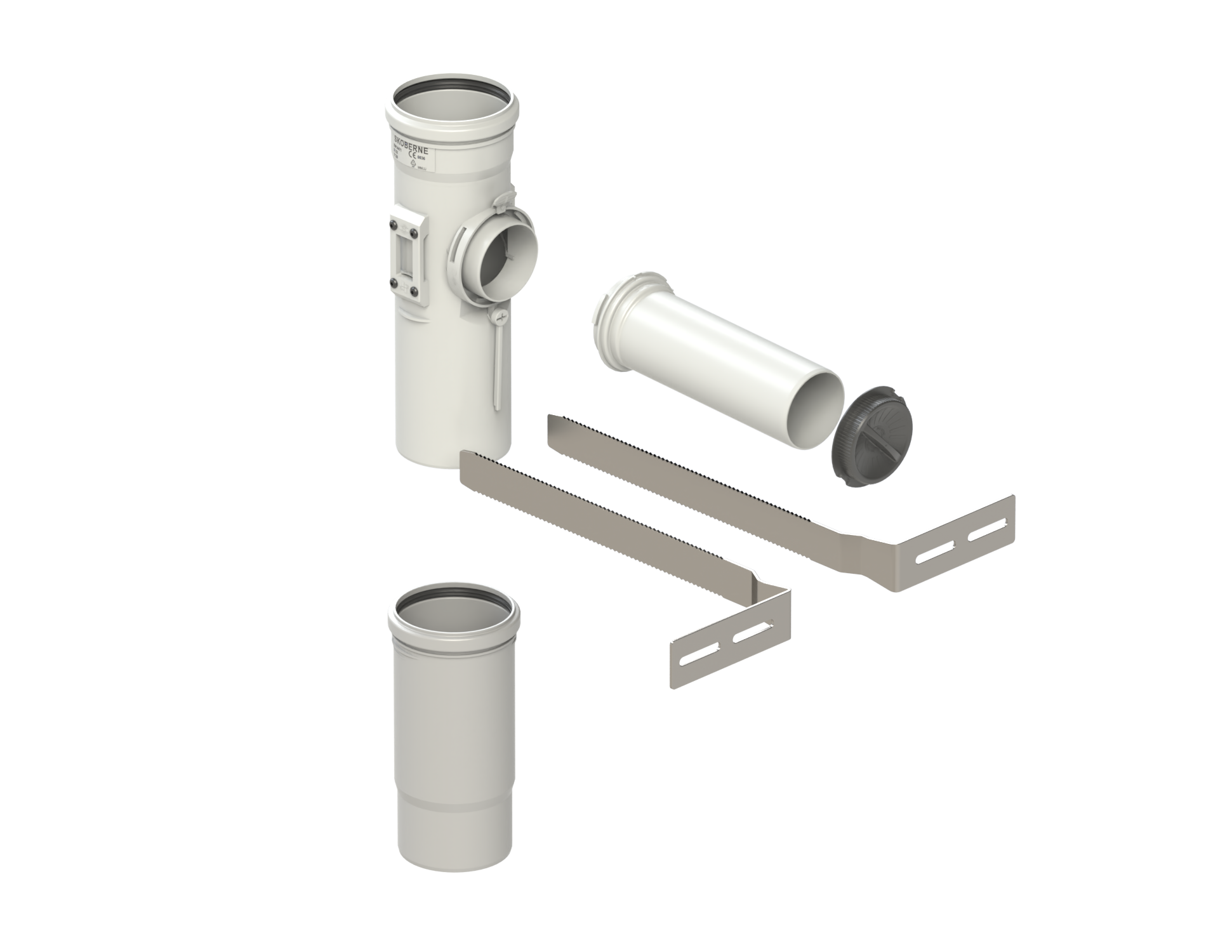

Plastic flue system

Description

Flue gas pipes made from plastic

For more than 30 years, Skoberne has been a leading manufacturer of plastic flue gas pipes and we are recognised for our exhaust gas systems for condensing boilers.

An overview of the benefits of plastic flue gas pipe products

- Durability

- Resistance to acidic condensates

- Insensitive to the effects of thermal cycling of condensing

- Easy repairs thank to simple push fit functionality

We have the right plastic flue pipe for every nationally and internationally recognised operating method:

- Single-wall - rigid

- Single-wall - flexible

- Concentric pipe (flue gas exhaust and air supply system)

These can be easily combined with each other and/or expanded, depending on the situation and requirement. As a result, unusual construction situations can also be overcome.

Product characteristics and applications of Skoberne’s plastic flue gas pipes

- Fuel: Oil or gas

- Operating mode: single wall and concentric (open vent or room sealed)

- Flue gas temperatures: up to 120°C

- Operating pressure: Positive and negative pressure

- Pressure class: P1 and H1

- Fire protection: "Flame retardant" (formerly DIN 4102 B1)

- UV resistance: stabilised

- Nominal diameters:

- Single wall rigid: range from 60mm to 315mm

- Flexible pipe: 60mm, 80mm, 110mm

- Concentric 60/100, 80/125, 110/150, 110/160 - TÜV-certified quality product made in Germany

Discover more from us