See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

Description

Agile and modular 3D manufacturing units, the NEXUS and MIRA automated micro-factories can be deployed quickly and cost-effectively, without the need for major construction work or complex industrial equipment.

Thanks to automated ejection of finished parts followed by the immediate restart of new print cycles, these 3D solutions offer a very fast return on investment. Ideal for rapid, customized, and flexible production, they are perfectly suited for small and medium series manufacturing as well as on-demand, near-the-customer fabrication. These solutions optimize resource usage, reduce space and energy requirements, and increase production speed by aligning the size of the production unit with that of the finished product. Compact and mobile, they can be installed in containers or directly integrated into an industrial site.

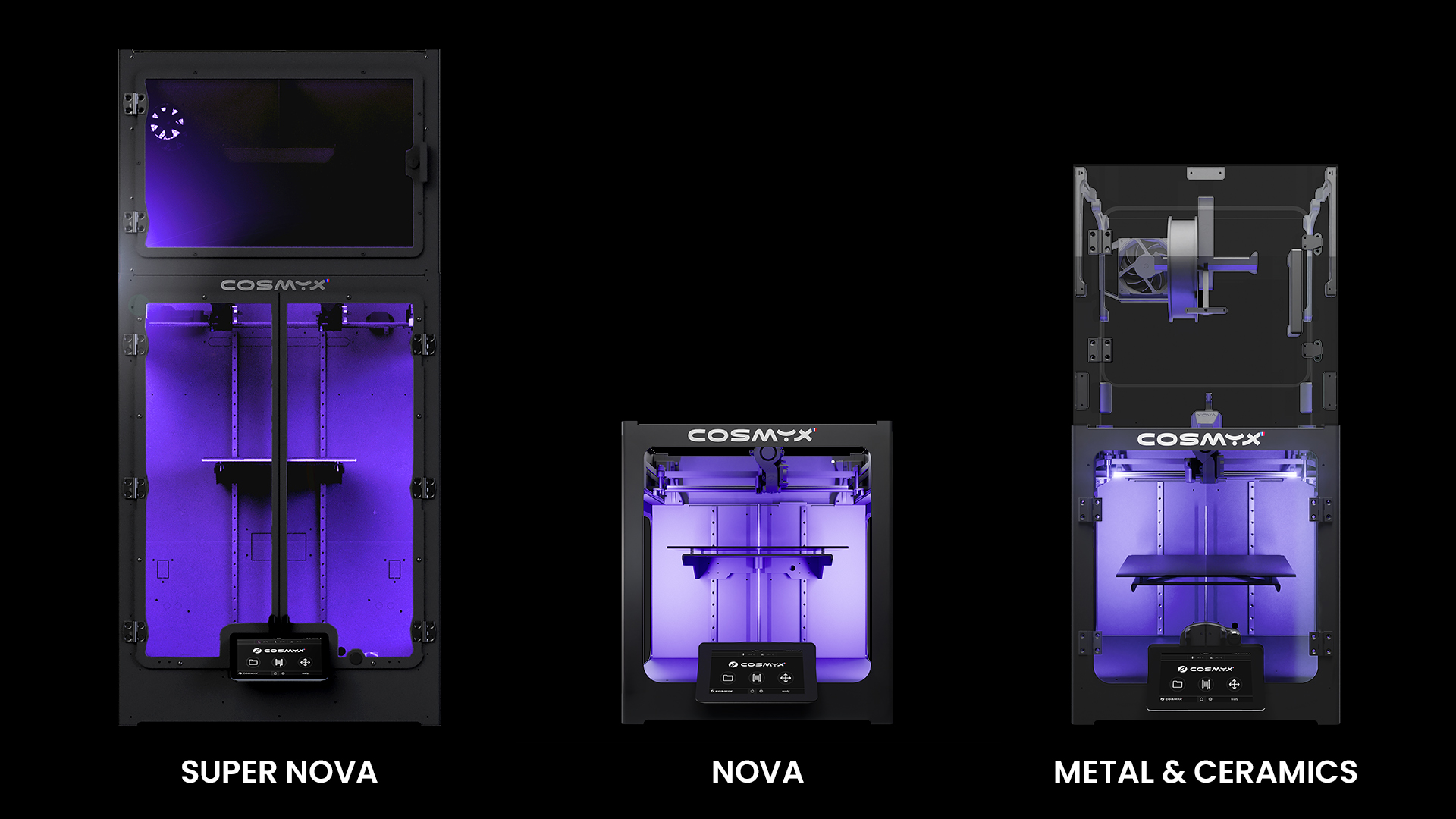

Capable of hosting 6 NOVA 3D printers, the MIRA 3D micro-factory enables continuous 24/7 production thanks to its automatic ejection system and ensures production integrity with real-time control of the print environment.

With an operational power consumption of approximately 2000 W, it stands out as a major asset for any production line. This agile and responsible connected, automated production solution can be equipped with a FANUC collaborative robot and the 3DS digital production chain by DASSAULT SYSTÈMES for even greater efficiency.

The NEXUS 3D micro-factory is designed to adapt to the evolving needs of industry. Thanks to its modular design, it allows the customization of the additive manufacturing unit by creating independent, flexible modules perfectly suited to all types of production requirements. Its automatic ejection system enables continuous part production, ensuring optimal performance for series manufacturing. This compact and portable solution facilitates the rapid setup of a 3D production unit.