See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

Description

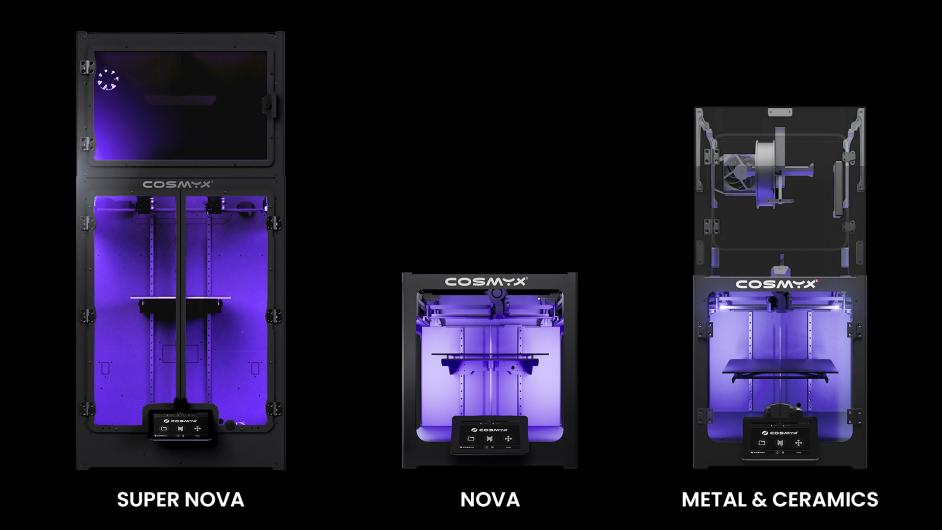

The NOVA and SUPER NOVA 3D printers have been developed to meet the high demands of industrial production.

With a movement speed capacity of 1000 mm/s and acceleration of 65,000 mm/s², they deliver high productivity without compromising on quality. Their robust steel frame ensures optimal stability, reducing vibrations and enhancing long-term precision. Thanks to their H-Bot technology, the presence of a single belt, and the integration of a minimal number of moving mechanical parts, our printers minimize maintenance costs while guaranteeing dimensional repeatability within 0.05 mm.

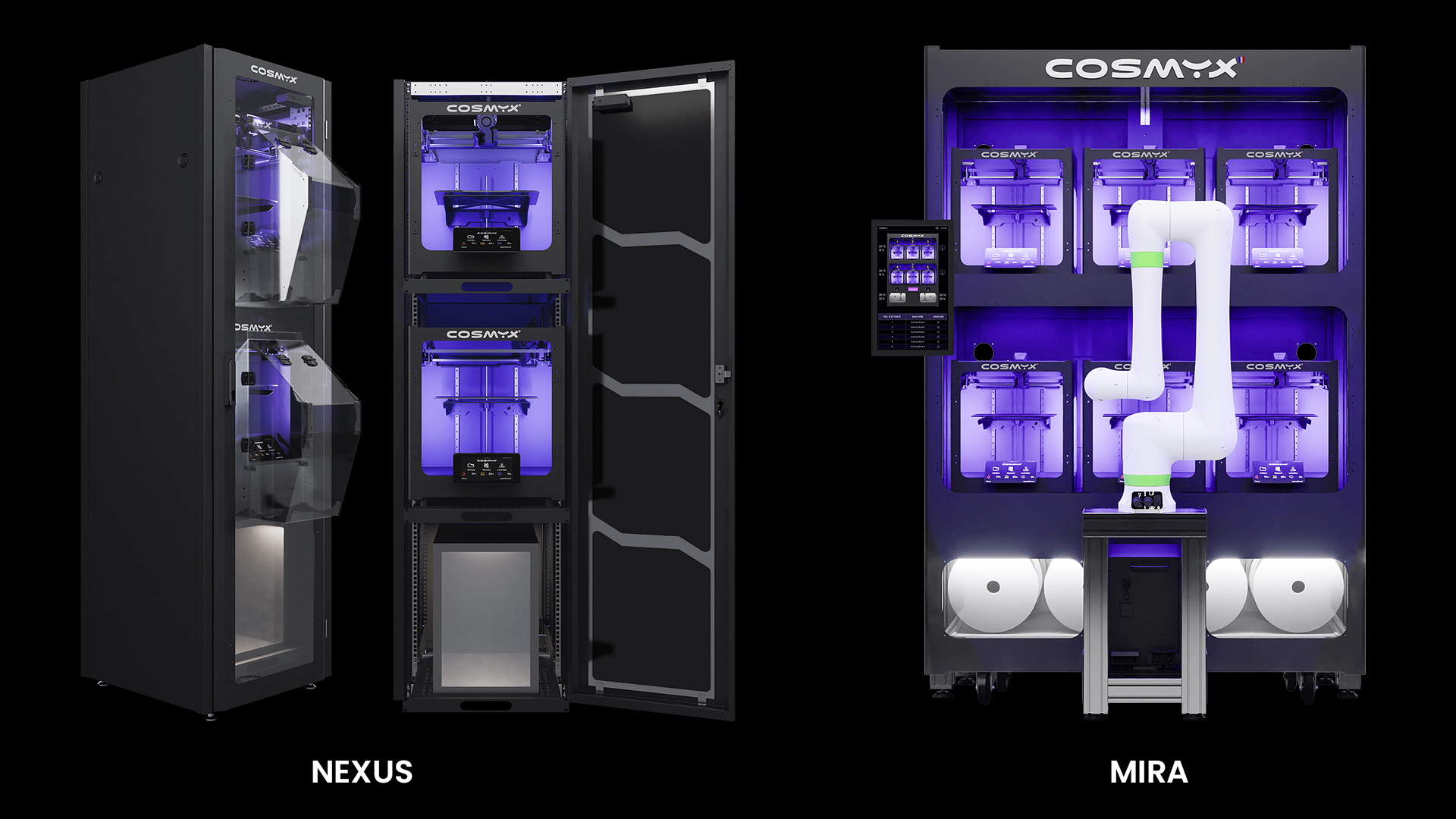

Designed as continuous-operation production tools, these 3D printers are ideal for enabling professionals to produce rapidly and in large volumes without sacrificing quality. Their interoperability facilitates integration into extensive machine fleets, offering a comprehensive and scalable solution for industrial needs. These solutions significantly increase productivity and promise a very fast return on investment, meeting the expectations of demanding professionals.

Remote control and fleet supervision are handled through our proprietary operating system CosmOS, which offers an intuitive and secure interface. This system ensures full traceability of production and advanced management of printing parameters, guaranteeing consistent quality and real-time optimization of operations.

These features make the NOVA and SUPER NOVA 3D printers robust, flexible, and high-performance solutions, perfectly suited to the growing demands of professionals seeking productivity, quality, and durability.