Find instead of search – our market directory offers a comprehensive overview of providers, suppliers, manufacturers and the latest solutions and products for Additive Manufacturing with detailed profiles of all Formnext exhibitors.

Make&Mill

Description

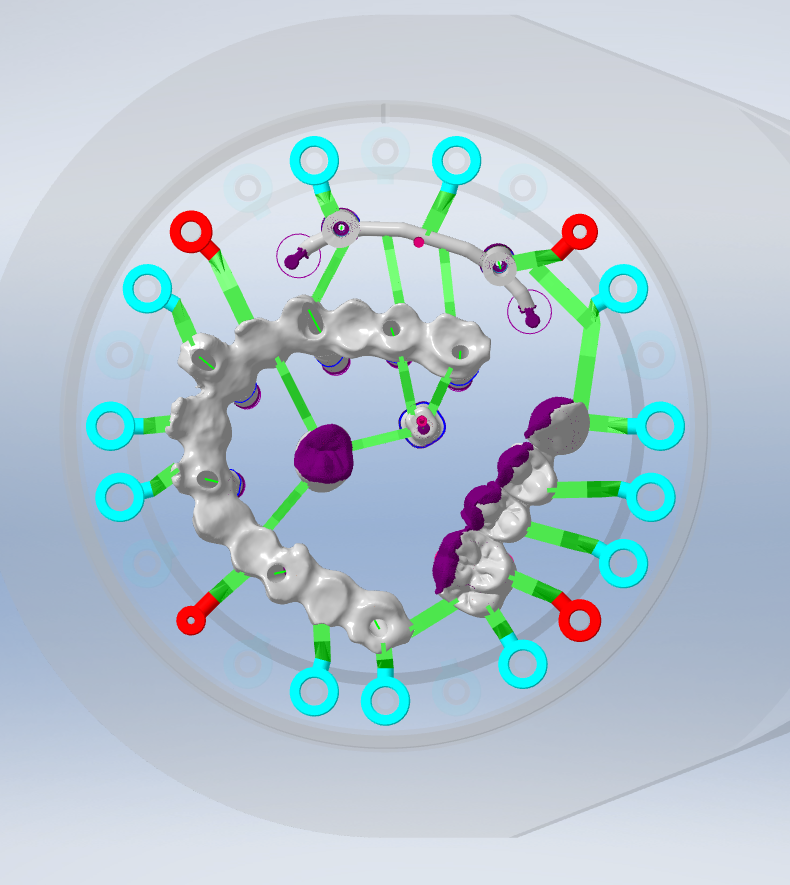

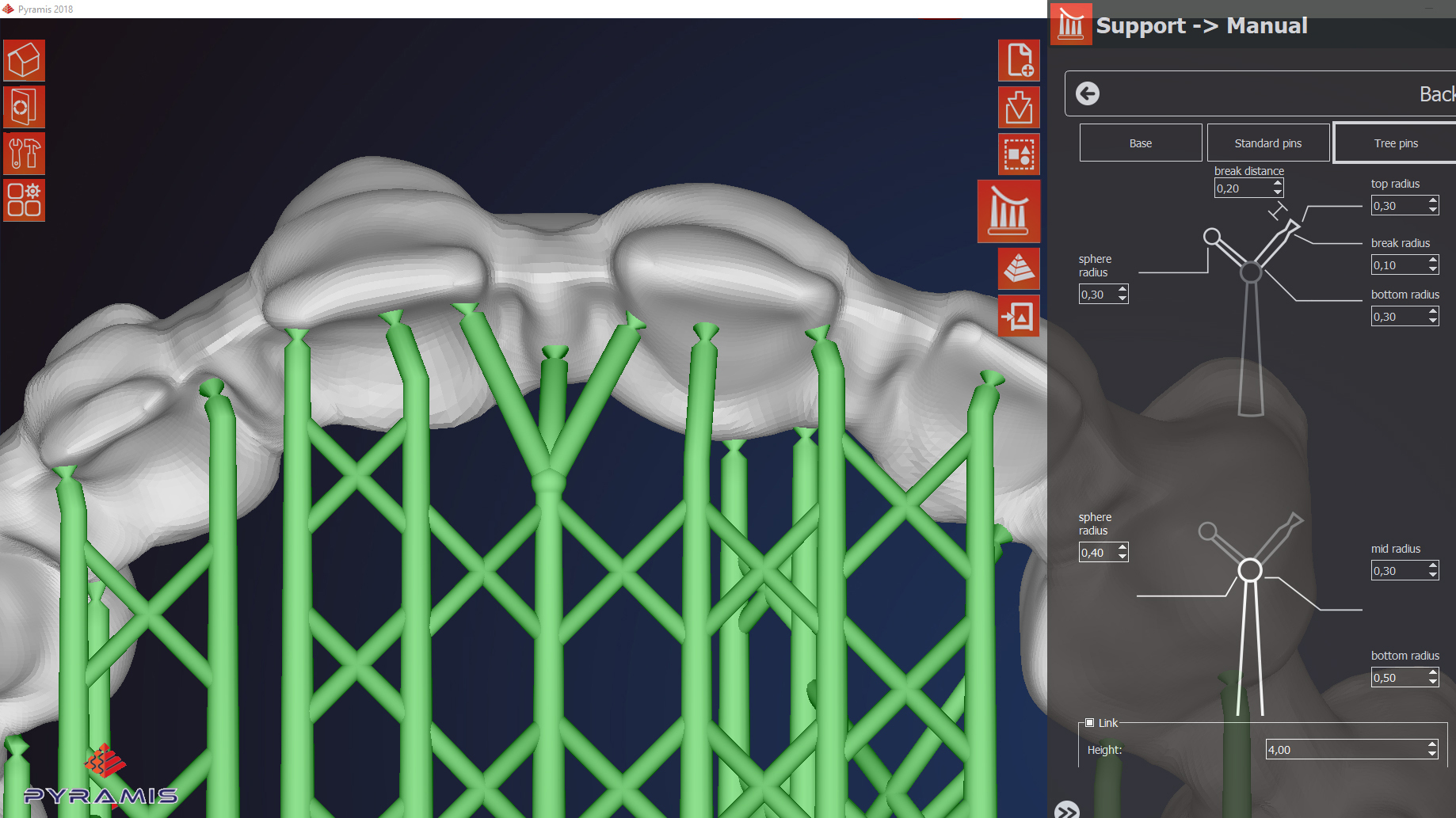

Make&Mill is a milling refining software that enables you to combine additive and subtractive manufacturing - all within a single application and through a single interface. The software provides multiple benefits including optimized processing times and repeatable accuracy of produced parts. It guides you through the nesting process for your sintering machine and produces toolpaths for refining restorations on your mill.

Precise management of material profiles on your sintering machines ensures you are printing properly scaled parts. On the milling side, all machining parameters are customizable to facilitate the best fit and finish.Moreover, Make&Mill is perfectly integrated with our 3D printing technology so that

you can easily combine the quickness and cost effectiveness of 3D printing with the precision of the milling process and execute all the steps all the steps of your dental manufacturing project in just few steps.

MAIN BENEFITS

- REDUCED LEARNING CURVE: Training times for new operators are significantly reduced.

- HIGHTLY CUSTOMIZABLE: Highly customizable by restoration type, material profile, and

milling strategy. - SMART: Thanks to Artificial Intelligence, many operations are performed automatically, saving you time and increasing machining accuracy.

- CHEPER: Make&Mill drastically minimizes your tool and material consumption without adding extra machining time.