Text and pictures: Metal AM, 23 January 2025

In the race to improve the productivity of PBF-LB Additive Manufacturing, machine OEMs have generally taken the path of adding more lasers.

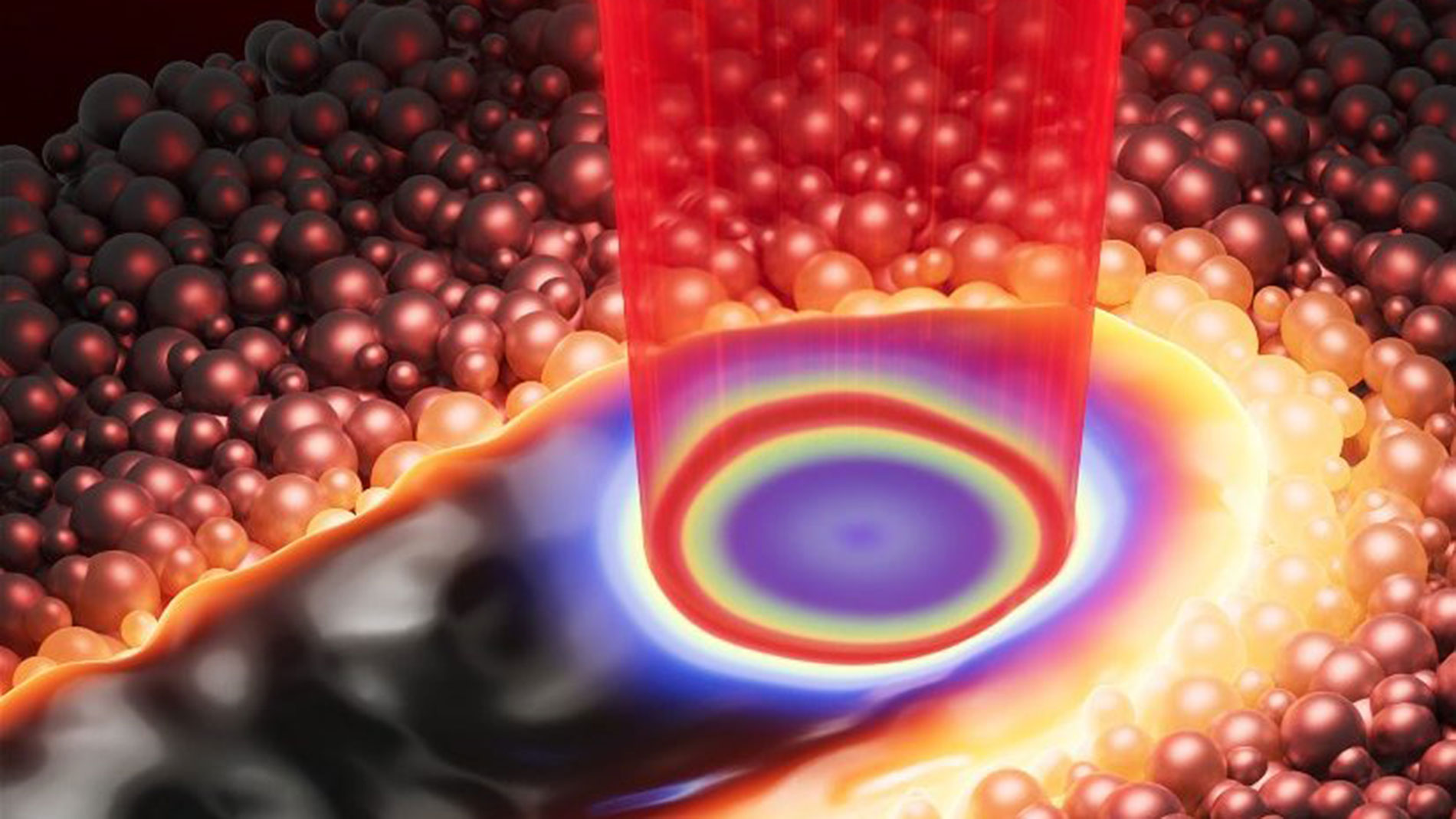

nLIGHT takes the view that it's not necessarily just more lasers that are needed, but beam-shaping lasers. By using dynamic beam shaping technology, significant increases in the productivity, stability and metallurgical capabilities of PBF-LB have been demonstrated. Given the technology's recent commercial success, with adoption by Aconity3D, AMCM, EOS and DMG Mori, we asked the nLIGHT team to review beam shaping technology and its potential impact on the AM industry.