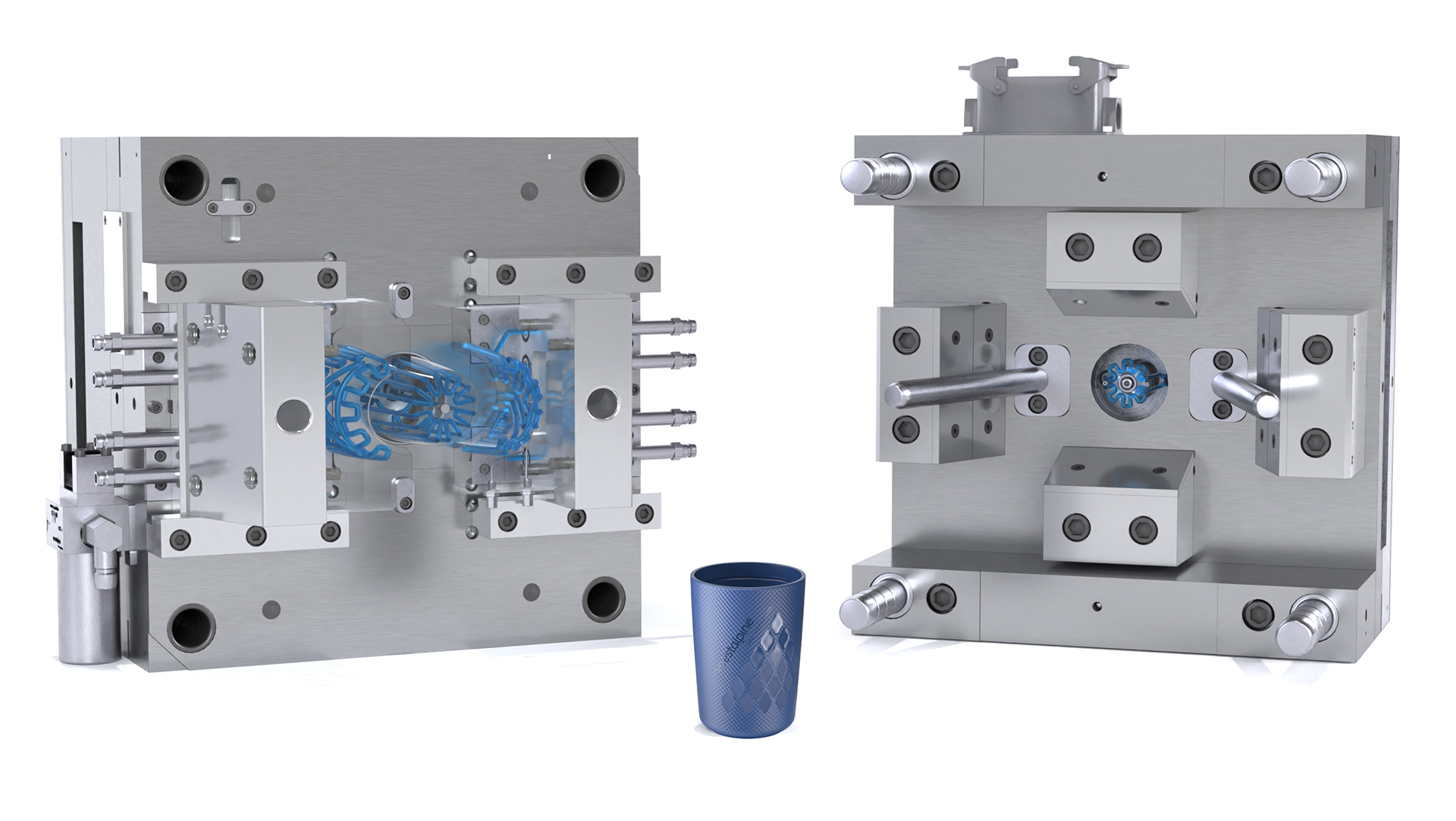

Plastic Injection Mold for a mug

INJECTION MOLDS WITH A HOLISTIC APPROACH

Innovative product design and cost-effective production require a targeted combination of our materials and technology expertise along the entire value chain. This also needs a close partnership between all those involved in the development process.

The voestalpine cup design with integrated functional structures and textures was realized through close cooperation in product design, tool design and the injection molding process. Thanks to a holistic approach, the cycle time could be reduced while at the same time improving the part quality. This was made possible by incorporating conformal cooling into the tool design at an early stage and optimizing the cooling medium distribution and the integration of sensors. The increased cooling capacity of conformal cooling also allows a higher mold wall temperature in specific areas, which ensures improved and reproducible molding of the microstructures without negatively affecting warpage. The coating process, which is tailored to the microstructures, protects them against wear without impairing their function.