See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

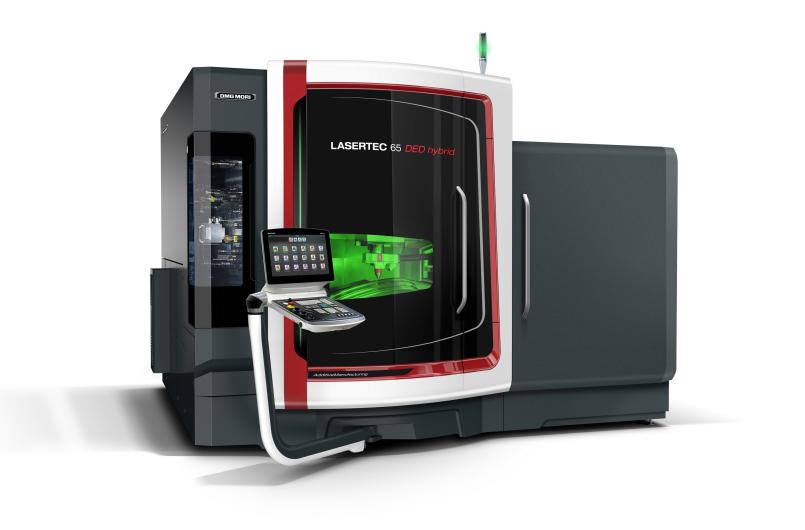

LASERTEC 65 DED hybrid

LASERTEC 65 DED hybrid

Description

Hybrid Complete Machining: Additive Manufacturing and Milling in one machine

Flexibility through combination of additive and milling machining process for 3D-parts in finished quality

- The laser head is handled by a fully automatic shuttle - without manual intervention

- 5-axis material deposition by coaxial nozzle for homogeneous powder distribution, independent from direction of laser deposition welding

- Full 5-axis milling machine in rigid monoBLOCK-design with < 129.2 ft² footprint

- Process monitoring and adaptive process-control (Closed Loop)

- User friendly and specifically developed software with operator-orientated user interface and CELOS integration

Process monitoring for highest process safety and quality management

- Continuous measuring and monitoring of the laser buildup process as well as automatic regulation of the laser power in real-time for homogeneous part qualities

Siemens NX: Complete Hybrid CAD / CAM – Module for additive and subtractive programming

- One software package for the complete process chain (design, additive process, substractive machining, finishing)

- Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine and movements for collision prevention

- Shorter time-to-market due to completeted integrated PLM software integration

Completely new product design potential

- 5-axis controlled laser deposition welding in machining centers makes new products possible

- New part features possible due to alternating material deposition and machining strategies

- Improved part performance by utilizing new material combinations (e.g. Copper + Inconel)

- Parts with inner channels for innovative, improved cooling