See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

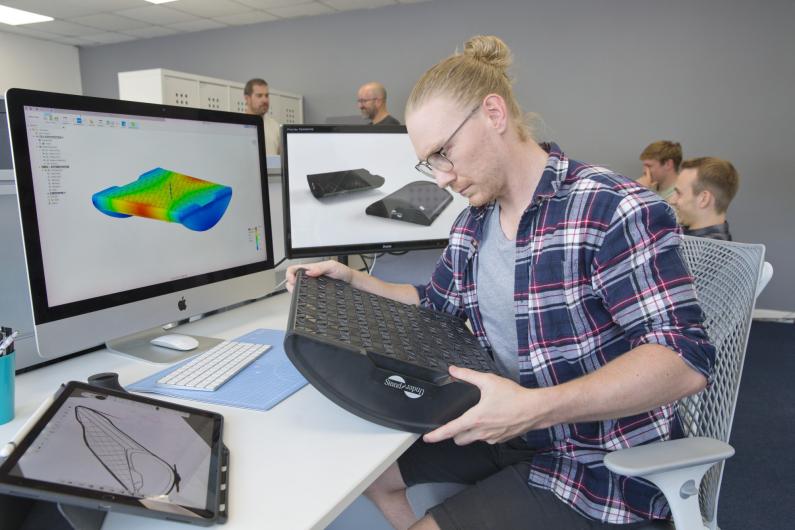

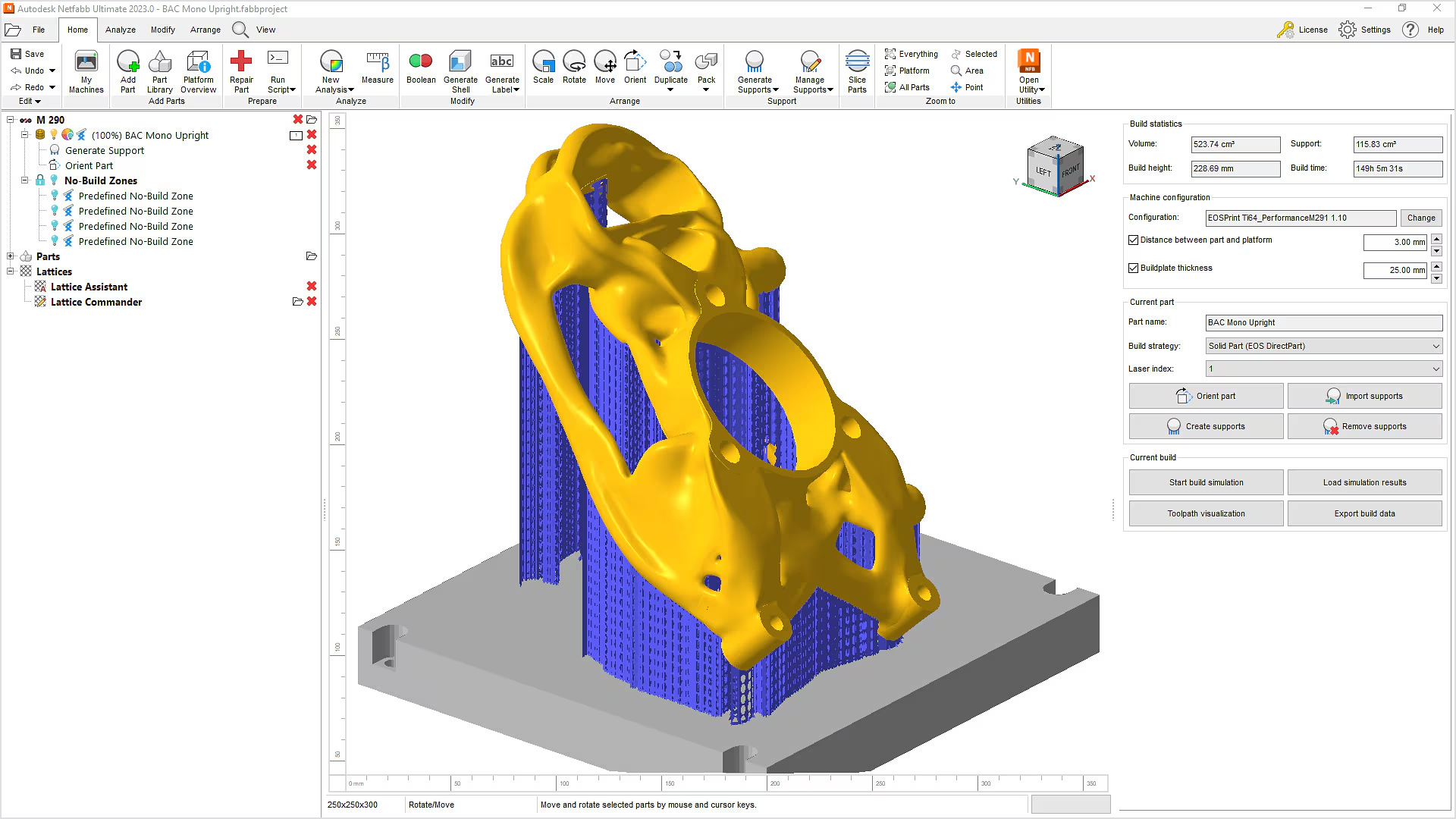

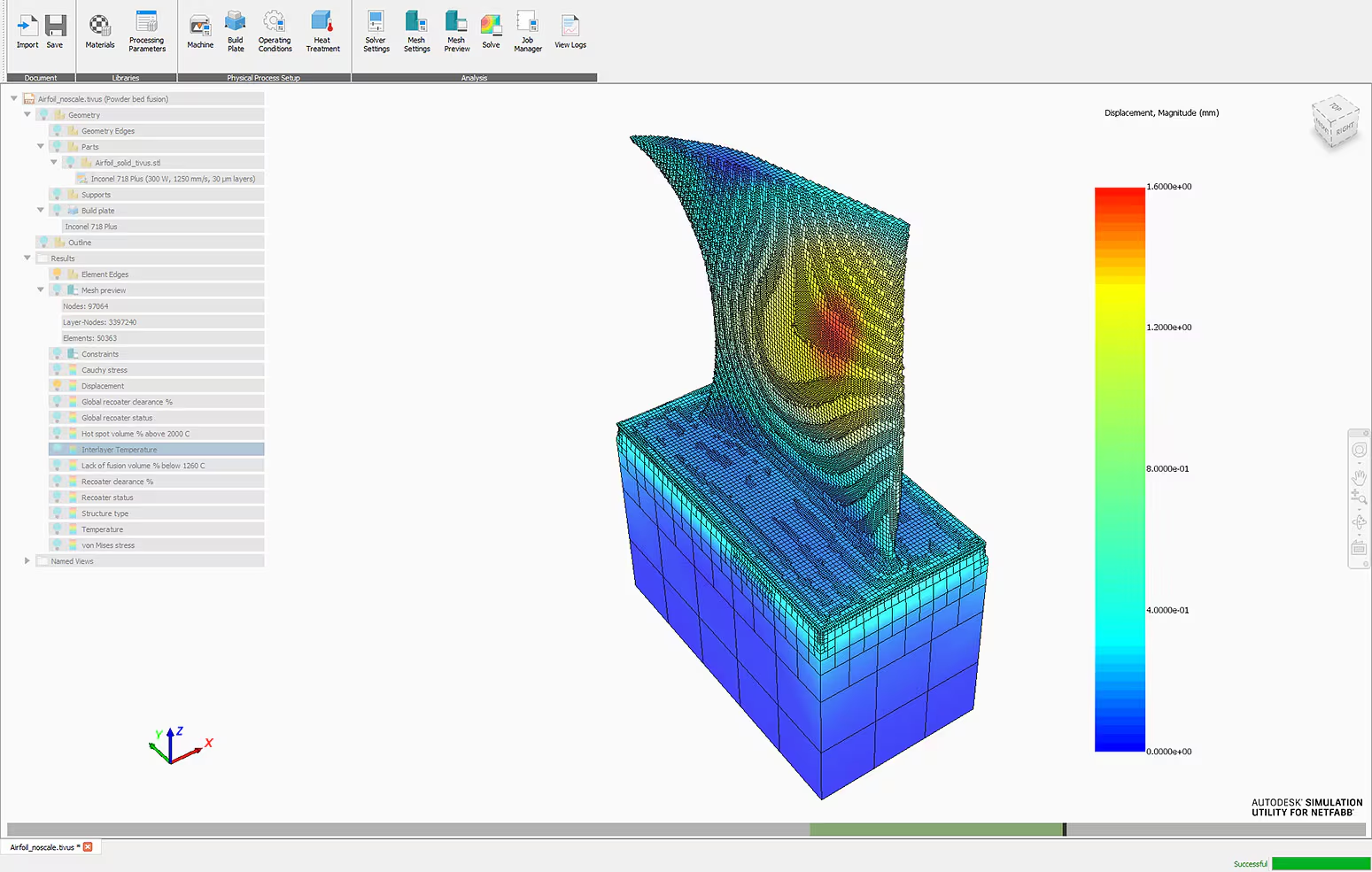

Description

Autodesk Fusion is the first and only integrated cloud CAD, CAM, CAE, and PCB software platform of its kind. With fusion you can streamline your product development, unify your team on one platform, save time and cost with automated workflows.

Further information in this product:

https://www.autodesk.com/products/fusion-360/overview