See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

AUTHENTISE LTD

Address

AUTHENTISE LTD

33 Foley Street

LONDON

W1W 7TL

Grossbritannien und Nordirland

Discover more from us

Follow us on

About us

SCALE YOUR OPERATIONS EFFICIENTLY AND RELIABLY

Data-Driven workflow management solutions for manufacturers to operate more efficiently and effectively across the entire supply chain.

Heres' a Rota for our Presentations:

TUE 2PM (Andre) Flows - Data Driven Production Management for Additive

WED 11AM (Andre) Digital Design Warehouse - Design Sharing, Insipiration and Additive Viability Assessment (with Castor)

WED 2PM (Tex) Threads - Engineering Collaboration and automated, AI-driven Technical Data Packages

THR 2PM (Vic) Material Management - End-to-end Powder Genealogy for Metal AM Production Use Cases

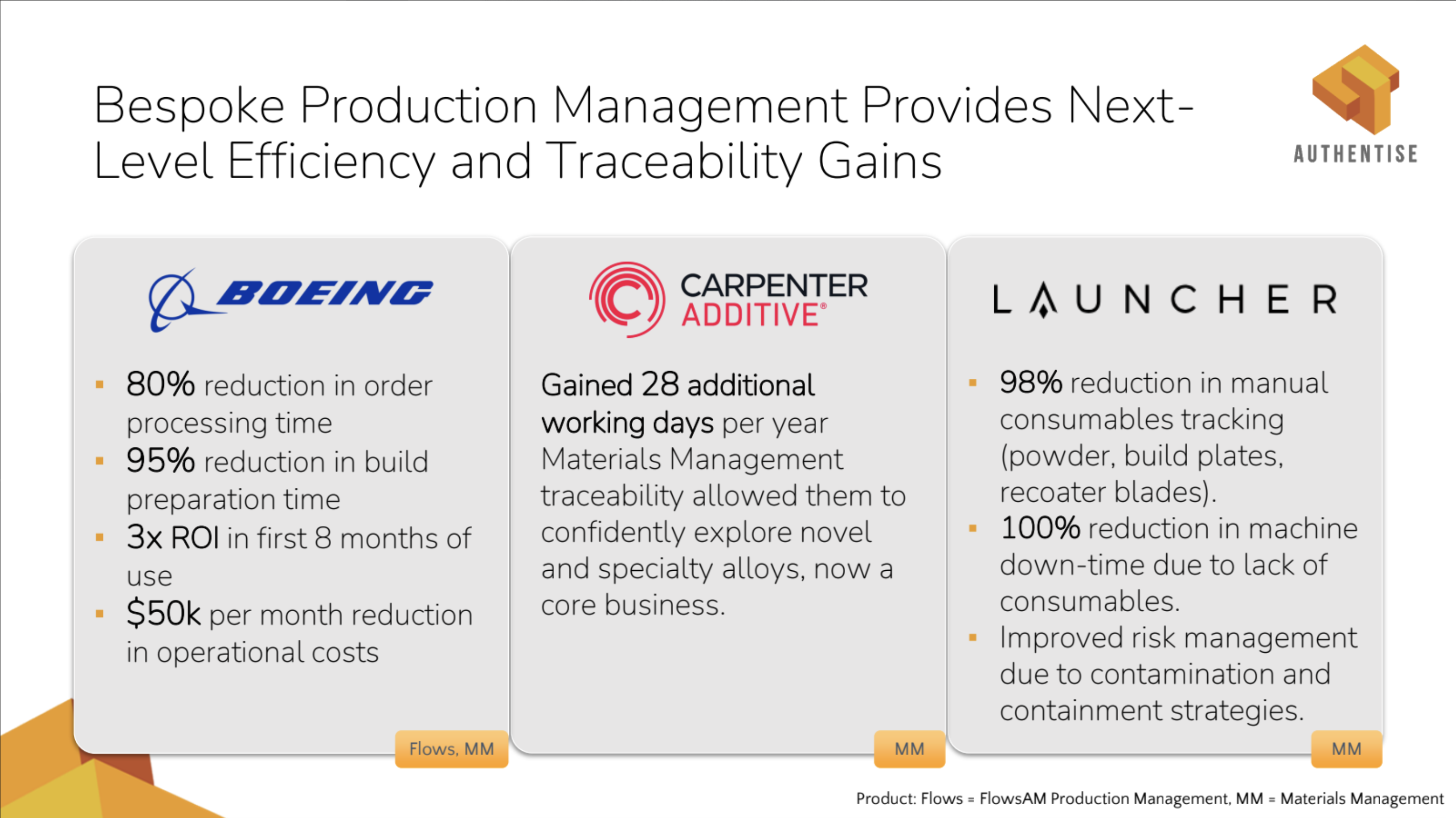

With over a decade of experience, our platform empowers global leaders to streamline complex processes, ensuring transparency, efficiency, and compliance at every step.

Trusted by Fortune 500 companies, our cutting-edge technology is backed by rigorous data security protocols, giving you confidence in the integrity of your operations.

Easily Plan, Manage, Execute & Track Industrial Engineering and Manufacturing Operations

Reduce cycle times with automation.

Industry Leading Material Tracking and Traceability with Real-Time Monitoring.

Manage your Digital Spare Parts & your Additive Initiatives in One Place

Allow different departments to develop & share their own designs

Quickly share new ideas by uploading any file, in any format

Share designs quickly without the need for 3D CAD software

Our Digital Material Genealogy Management module provides advanced Material Workflow Management for Additive Manufacturing.

Automatically track utilization history by material

Number of reuses, amount used, data of first use, user action

Track real-time material status, utilization, and quantity remaining

Virgin and reused powder cycles

VMI actively monitors and replenishes Build Plate Stock, ensuring you always have enough plates on hand.

Queue Build Plates

Dashboard Visibility

Effortless Verification

Traceability Reporting

Record key plate measurements including Thickness, Flatness, and Parallelism for confidence in build plate quality.

Bring your organisation together.

There's a reason why so many are switching to Flows.

Multi-location reporting, compliance and process improvements becomes a breeze, and with its partner integrations it offers the best in class tools, to help companies in the industry improve traceability and deliver quality!

Partner with Authentise to leverage our expertise and transform your manufacturing processes into a seamless, scalable, and secure ecosystem!

Keywords

- Additive

- manufacturing operations

- workflow software

Our Products

Flows

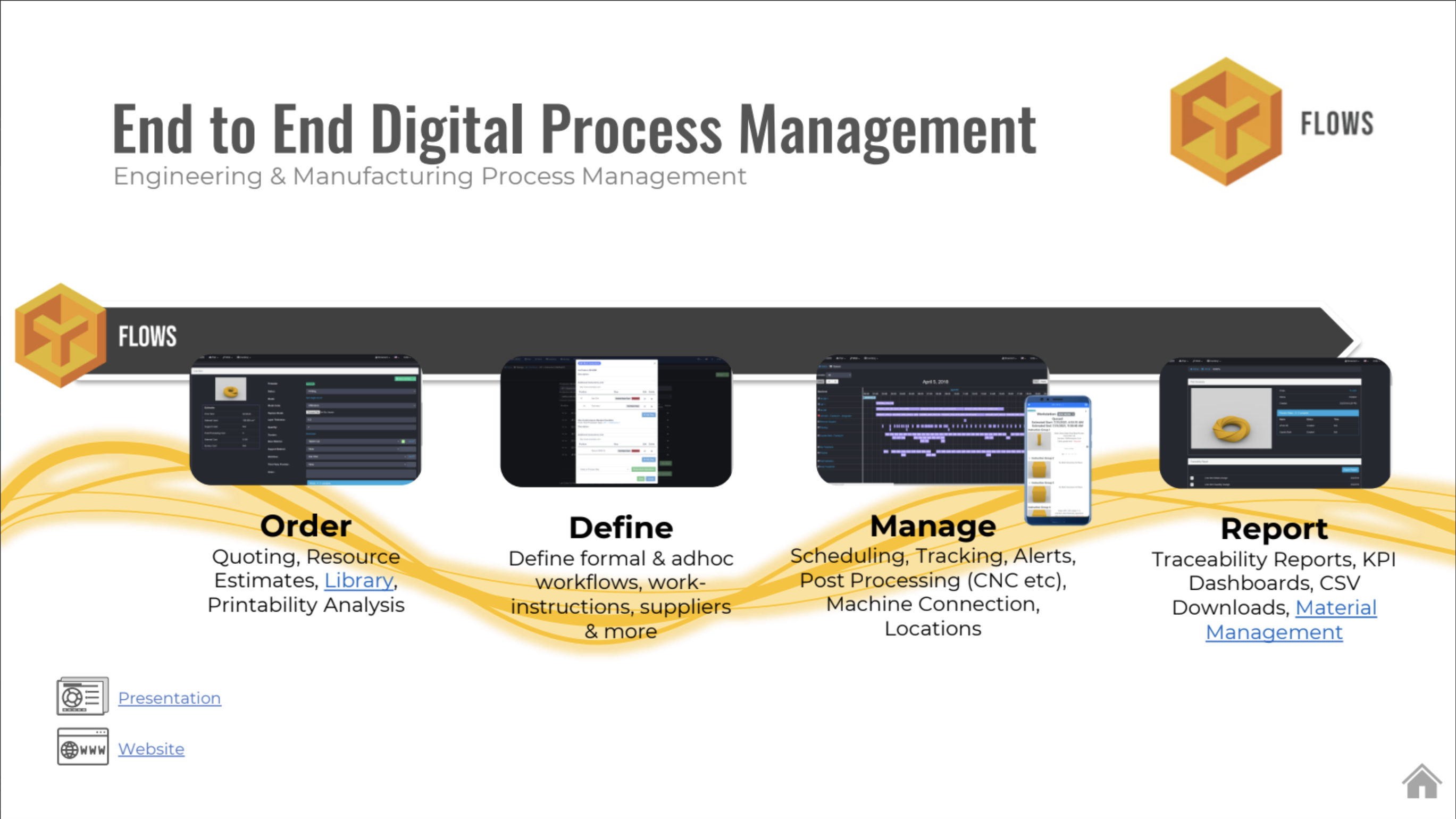

MANAGE YOUR ADDITIVE WORKFLOWS WITH FLOWS AM

Whether you're making prototypes or production parts, Authentise helps manage your processes efficiently, ensure processes are followed and capture all resulting data.

Leverage the digital thread to bring transparency and efficiency to your fingertips. Multi-location reporting, compliance and process improvements becomes a breeze, and with Authentise's partner integrations you'll always be sure to have best in class tools.

Centralized Order Intake and Outsourcing

All the data you need to stay informed and act nimbly on your orders in one, user-friendly platform.

Manage orders internally, across multiple locations or through third parties, without skipping a beat.

Production Planning & Scheduling

Let production data power your scheduling process.

Flows AM knows when your equipment is booked and schedules new runs at the earliest open slot, with their attached workflow steps following suit.

On-Demand Digital Parts Catalog

Features like the Model Library make it immediate and reliable to reorder parts for production, based on CAD and print parameters. For customer showcase or lab testing, just pick and choose.

Real-time Machine Monitoring

Direct machine connection gives you access to past and live production data. Store data from past orders to process into analytical KPIs and get live updates on machine status like error messages and more right in your inbox.

Create any report or dashboard you need with our unique integration with Microsoft Flow, or via API.

Quality Assurance & Reporting

Data never leaves the pipeline in FlowsAM: Machine data is captured as is operator feedback through the app.

Now, custom automated reports can be downloaded with a single click or sent directly to customers. Filter by processing step or user change, it’s never been easier to learn from your operations.

Guidelines Rules Engine

Create a template resource that is provided to a user when required

Thresholds trigger suggested changes in behaviour or parameters that will ensure a more successful production outcome.

Material Management

Our Digital Material Genealogy Management module provides advanced material workflow management for additive manufacturing.

Comprehensive Materials Genealogy Visualisation & Reporting

- Simple visualization of all actions/events and material history

- Automatically track utilization history by material

- Number of reuses, amount used, data of first use, user actions

- Captured in Traceability Report for every Part

- Online or Downloadable version

- API access to report for reuse

Intelligent Powder Management & Inventory Level Tracking

- Automatically track material availability across inventories and in-machine

- Track real-time material status, utilization, and quantity remaining

- Virgin and reused powder cycles

- List all builds/orders completed with material

- Automatic material Traceability Report generation

- Show material history & QA data

- Ability to attach reports

Real Time Material & Machine Association

- Ability to load and unload material from machine using Web & QR app

- Track history of material actions (split, blend, sieve, test)

- create material genealogy which tracks the evolving batches

- Associate material history to build

- Recorded in material traceability & part traceability reports

- Keep track of employee actions on the production floor

- When was material added, how much, by whom

Simplifying Material Handling on the Shop Floor

- Machines and material actions tracked using QR app

- Select action by scanning qr code on material + machine

- Create customized material handling & process steps with Work Instructions

- New powder shipments

- Post-printing activities

- Operator actions automatically captured in traceability report

- Keep track of material levels, history and status with material travelers

Automated Reordering

- Set threshold inventory level per material and location

- Automated reorder when threshold is reached

- Simple reconciliation upon receipt

- Easy integration with ERP systems for Purchase Orders

Threads

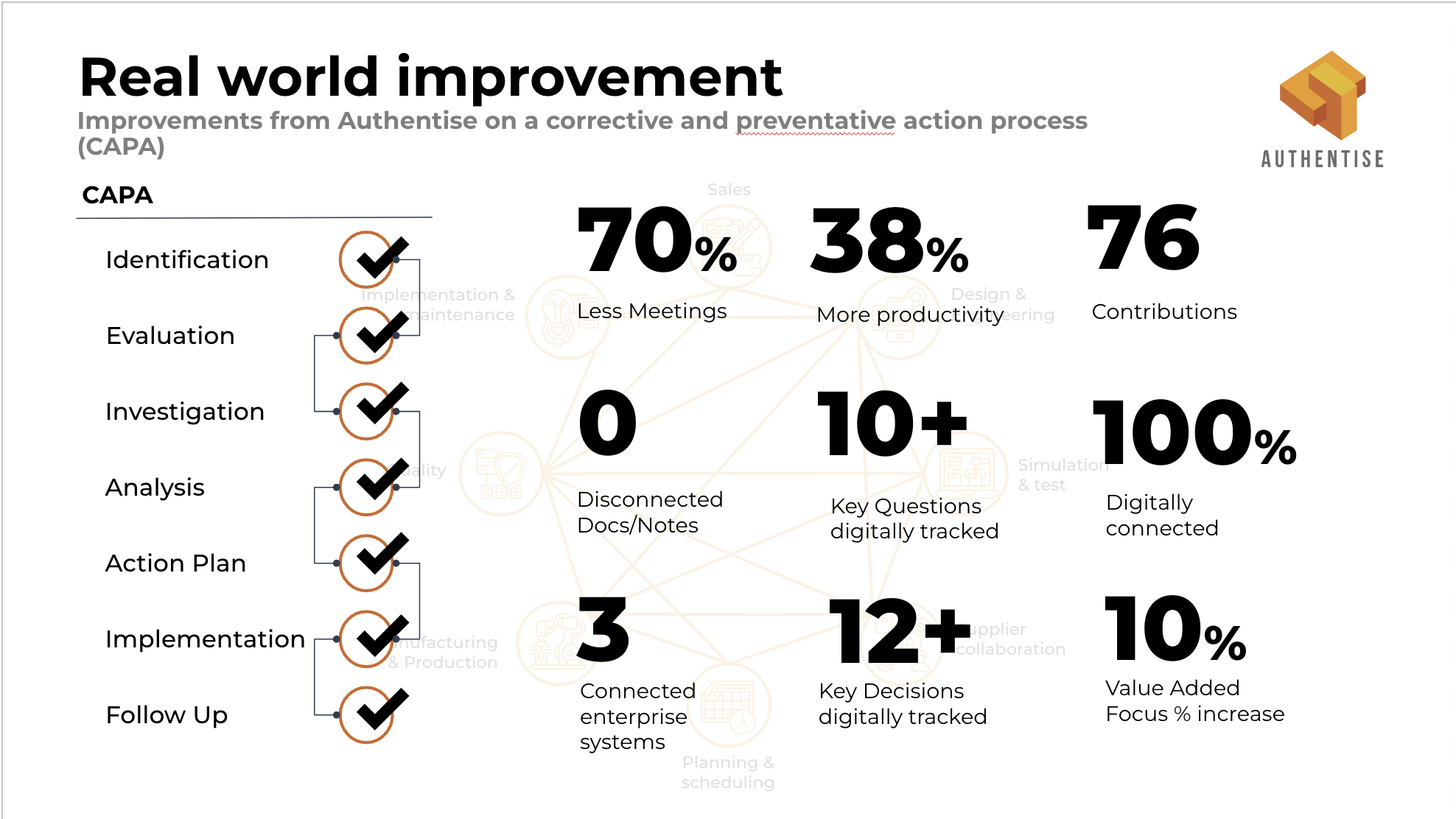

EFFECTIVE, ON-TIME, ENGINEERING PROJECTS

Unlock hidden project data in a single place so that your product collaborators are painlessly onboarded and stay in-sync.

Unlock Hidden Data with ThreadsBot

Quickly navigate project history and understand decision-making processes, for informed actions and fast project timelines.

Rapid Understanding with AI

Team members no longer bombard you with a million questions. Now ThreadsBot can find them project statuses, decisions, documents and timelines. All they need to do is ask it.

Collaborate on cad models with Threads3D

Never misinterpret feedback again. Use Threads3D to add detailed notes to 3D designs and discuss feedback visually, in real-time.

You Cannot Afford Knowledge Loss

All your knowledge captured transparently. Be they ideas, documents, decisions or events, all organised into contextualised Threads that allow you to see the bigger picture...

Role-Based Access Control

- Granular Permissions: Users are assigned roles (e.g., operator, manager, admin), each with different levels of access to sensitive data or features.

- User Authentication: Controls who can access specific threads, documents, or workflow data, preventing unauthorized personnel from viewing sensitive information.

Secure Collaboration Channels

- Private and Encrypted Communication: Ensures that all communication within threads (chat, comments, file sharing) is secure and private, visible only to authorized users.

- Tamper-Proof Messaging: Prevents modification of communication records to ensure that any actions taken within threads are traceable and secure.

Audit Trails and Activity Logs

- Detailed Logs: Every user action (file access, modifications, thread participation) is logged to track who accessed what and when.

- Compliance and Accountability: Helps ensure compliance with industry standards (e.g., ISO, ITAR) and holds users accountable for their actions within the system.